Universal material testing machine for variable rotating speed pump control hydraulic servo loading system

A material testing machine, hydraulic servo technology, applied in the direction of analyzing materials, servo motors, mechanical equipment, etc., can solve the problem of pollution-sensitive whole machine failure rate and other problems, achieve excellent energy saving effect, reduce the probability of failure, and simplify the hydraulic circuit. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

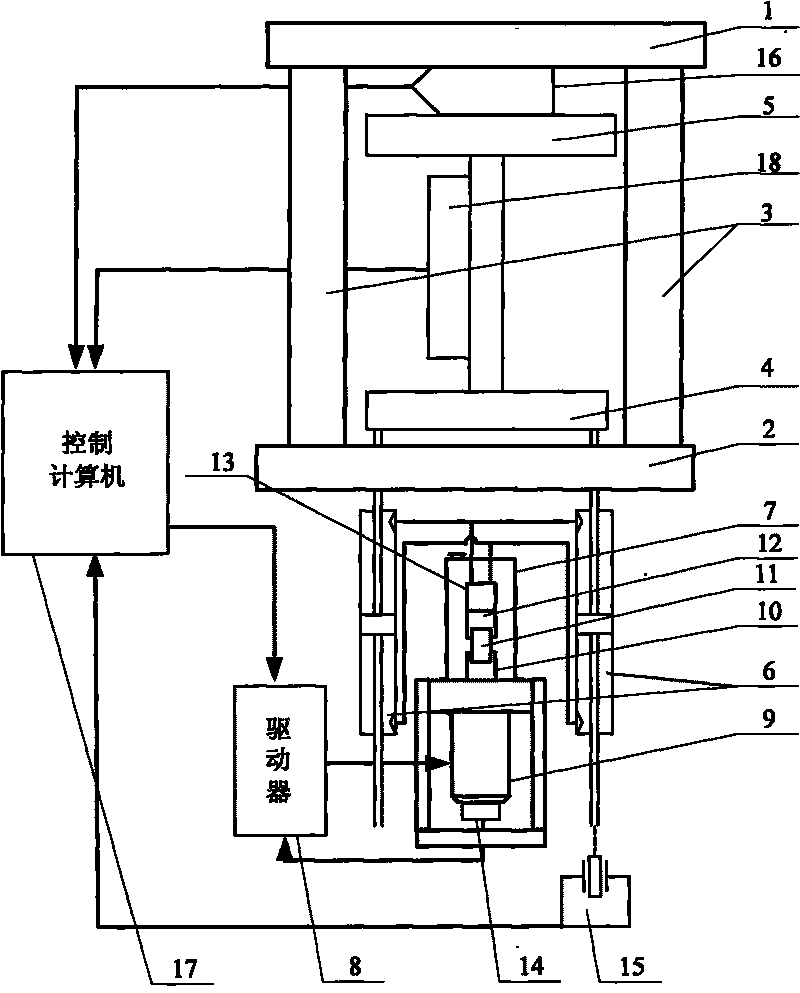

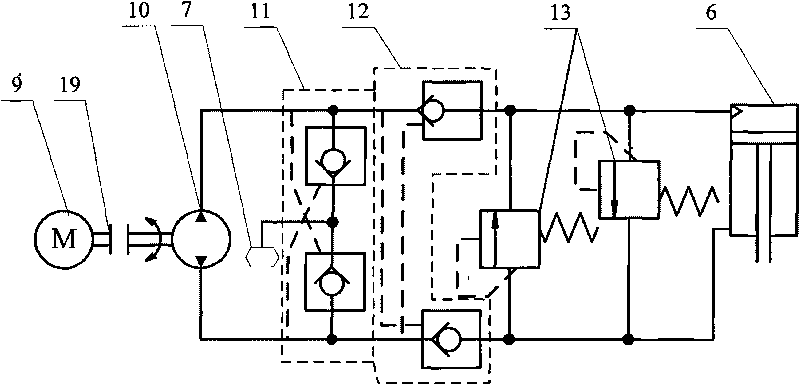

[0010] Specific implementation mode one: the following combination figure 1 and figure 2 Describe this embodiment. This embodiment includes an upper beam 1, a lower beam 2, two columns 3, a workbench 4, a clamping mechanism 5, and an extensometer 18. The two columns 3 form a frame with the upper beam 1 and the lower beam 2. , the frame is supported by the base and bracket of the whole machine, and it also includes two hydraulic cylinders 6, closed oil tank 7, driver 8, motor 9, bidirectional quantitative pump 10, oil replenishment valve 11, bidirectional lock valve 12, two A relief valve 13, an encoder 14, a displacement sensor 15, a pressure sensor 16 and a control computer 17,

[0011] The power output shaft of the motor 9 is connected to the power input shaft of the two-way quantitative pump 10 through a coupling 19, and the two-way quantitative pump 10 and the two hydraulic cylinders 6 form a closed circuit through two oil circuits, and one end of one oil circuit simult...

specific Embodiment approach 2

[0015] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the oil replenishment valve 11 is composed of two hydraulic control check valves, and the two hydraulic control check valves are connected in parallel between the two oil circuits. The oil inlets of the two hydraulic control check valves communicate with the oil inlets and outlets of the closed oil tank 7 at the same time. Other components and connections are the same as those in Embodiment 1.

[0016] The oil outlets of each of the hydraulic control check valves are respectively connected to different oil passages, and the control oil ports of each hydraulic control check valve are respectively connected to the oil outlets connected to the oil outlets of another hydraulic control check valve. The roads are connected.

[0017] The oil replenishment valve 11 is connected in parallel on the closed circuit and communicated with the closed oil tank 7. Its function is to replenish oil from the clo...

specific Embodiment approach 3

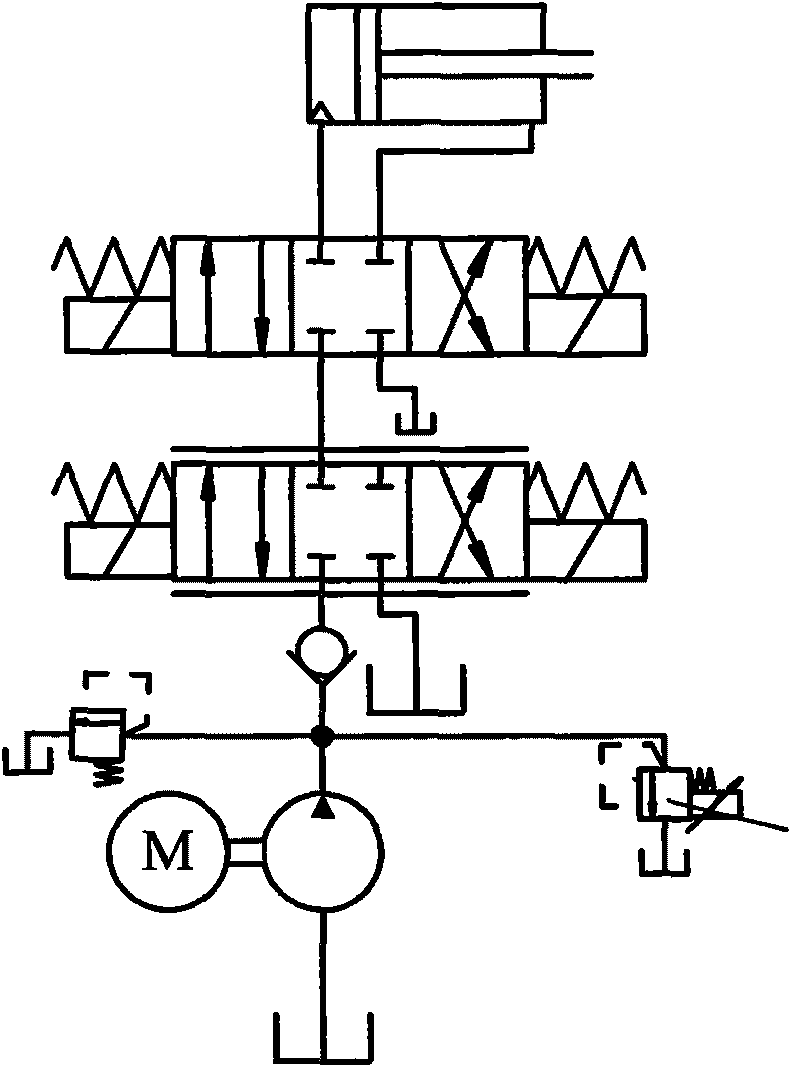

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the two-way lock valve 12 is composed of two hydraulically controlled one-way valves. Other compositions and connections are the same as those in the first or second embodiment.

[0019] The oil outlets of the two hydraulically controlled one-way valves described in this embodiment are respectively connected with two different oil ports of the hydraulic cylinder 6, and the oil inlets of the two hydraulically controlled one-way valves are connected with the two-way quantitative pump 10 respectively. Two different oil ports are connected, and the control oil port of each hydraulic control check valve is respectively connected with the oil passage connected with the oil inlet port of the other hydraulic control check valve. The function of the two-way lock valve 12 is to keep the pressure of the hydraulic cylinder 6 in the non-working state, and then prevent the piston rod of the hydraulic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com