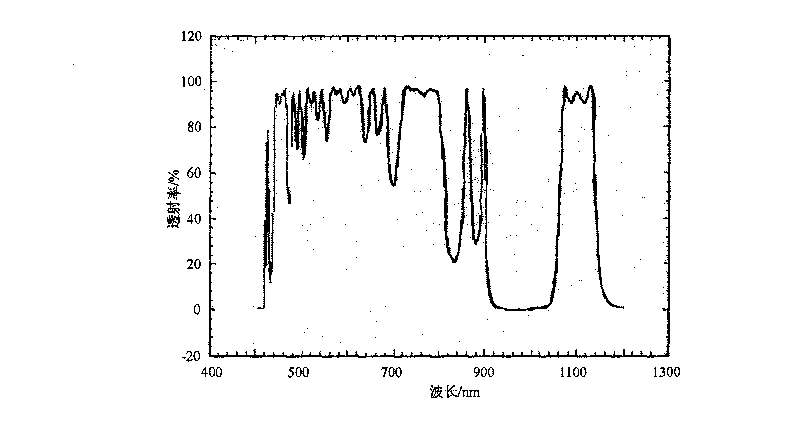

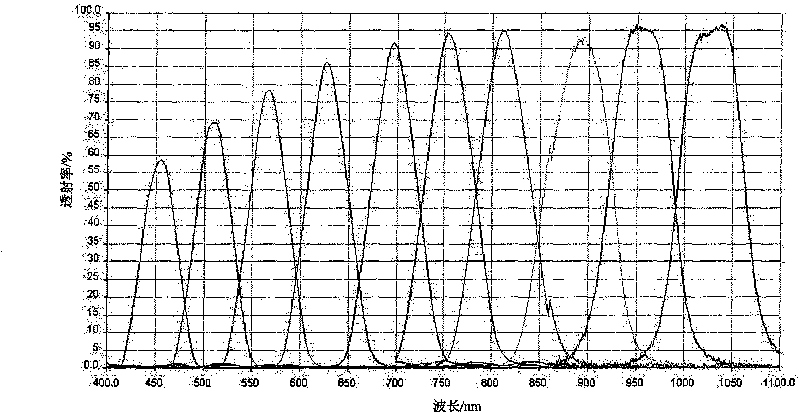

Linear gradient optical filter of 0.4 to 1.1 micrometers and preparation method thereof

A linear gradient filter and substrate technology, which is applied in the field of optical systems, achieves the effects of simple manufacturing process, portability and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The linear gradient filter of a 0.4-1.1 micron linear gradient filter of the present invention uses K9 glass as a coating base, and titanium dioxide and silicon dioxide as coating materials. The film system adopts three-half-wave film system, and the designed film system is

[0024] K9 / (LHLH2LHLH) 3 / Air.

[0025] Wherein H and L are the 1 / 4 wavelength optical thicknesses of titanium dioxide and silicon dioxide of high and low refractive index materials respectively.

[0026] Its concrete preparation method is as follows:

[0027] (1) Clean the vacuum chamber: Use a vacuum cleaner to remove the film layer that has fallen off in the vacuum chamber, and then wipe the inner wall of the vacuum chamber with a degreasing gauze dipped in absolute ethanol;

[0028] (2) Ultrasonic cleaning of the substrate: put the substrate into a glass container, ultrasonically clean the substrate with analytical pure acetone for 10 minutes, then ultrasonically clean it with analytical pure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com