Laser cutting system for pole piece of power battery

A technology of laser cutting and power battery, which is applied in the direction of laser, electrode manufacturing, laser welding equipment, etc., can solve the problems of unstable battery capacity, fast cutting die damage, and many metal scraps, so as to save the cost of cutting die consumption, The effect of cost saving and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

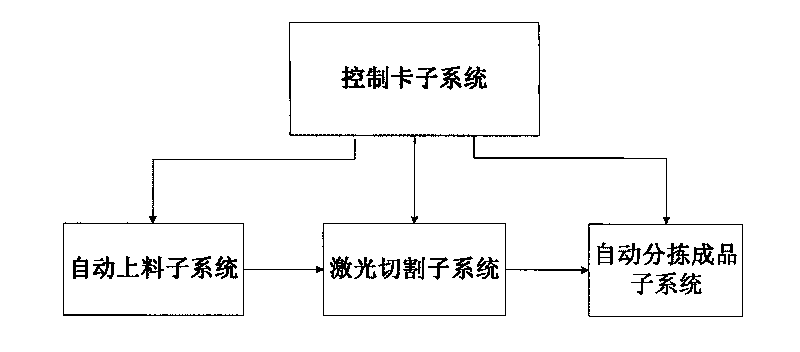

[0021] refer to figure 1 , Power battery pole piece laser cutting system, including automatic feeding subsystem, laser cutting subsystem, automatic sorting finished product subsystem and control card subsystem, automatic feeding subsystem will send the divided pole piece material into the laser cutting subsystem, laser cutting The subsystem will cut the incoming pole piece material according to a given size, and the automatic sorting finished product subsystem will put the cut pole pieces and side materials into the finished product box and waste recycling box respectively, and the control card system centrally controls the automatic feeding subsystem, laser Cutting subsystem, automatic sorting finished product subsystem.

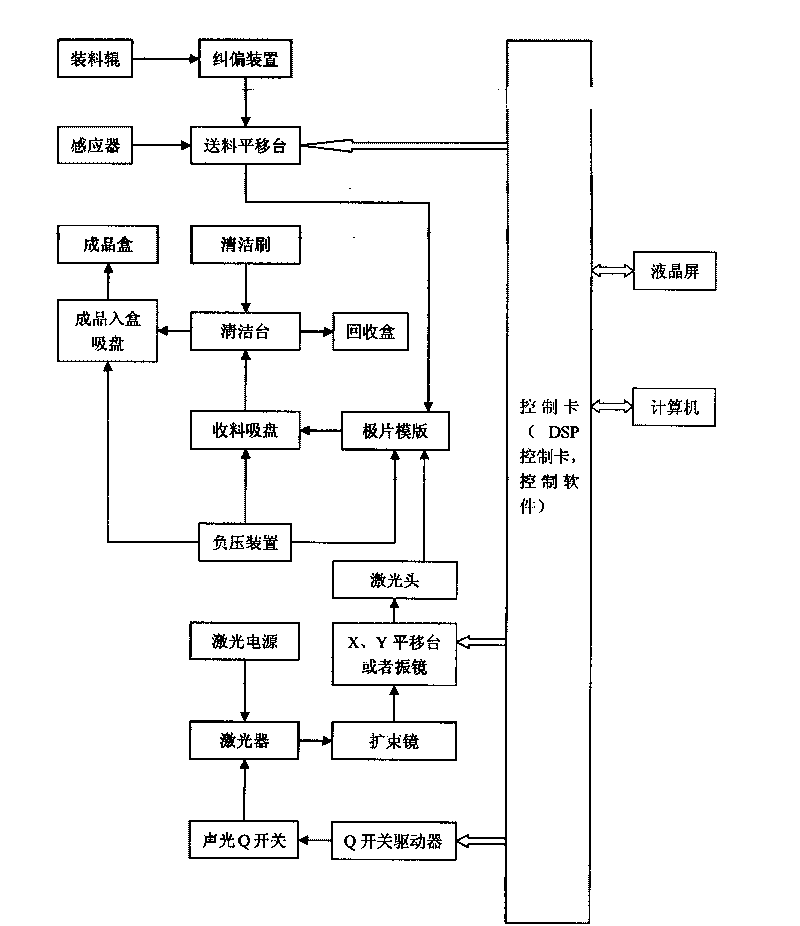

[0022] refer to figure 2 , further, the automatic feeding subsystem includes a charging roller, the output end of the charging roller is connected with a deviation correction device, the output end of the deviation correction device is connected with a fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com