Wet etching method of barium-strontium titanate and bismuth zinc niobate composite films

A technology of zinc-bismuth niobate and strontium-barium titanate, which is applied in the field of microwave medium processing, can solve difficult problems such as substrate surface precipitation, and achieve the effects of high graphics conversion accuracy, wide application range, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and embodiments.

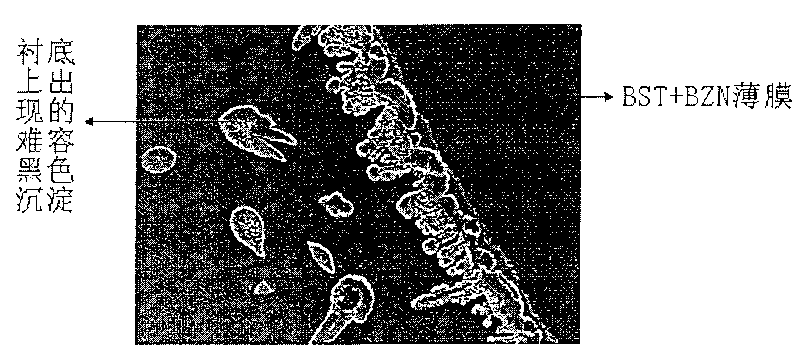

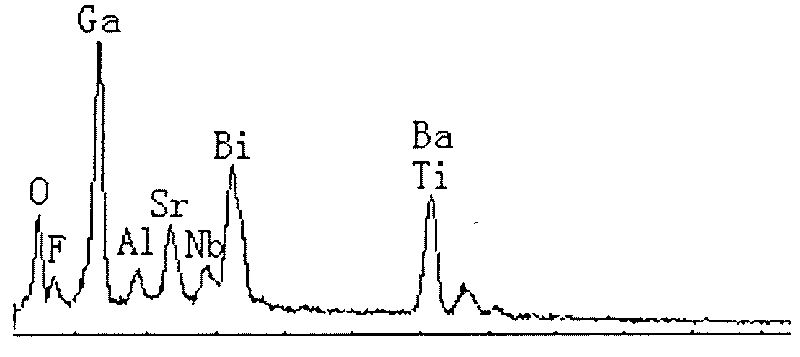

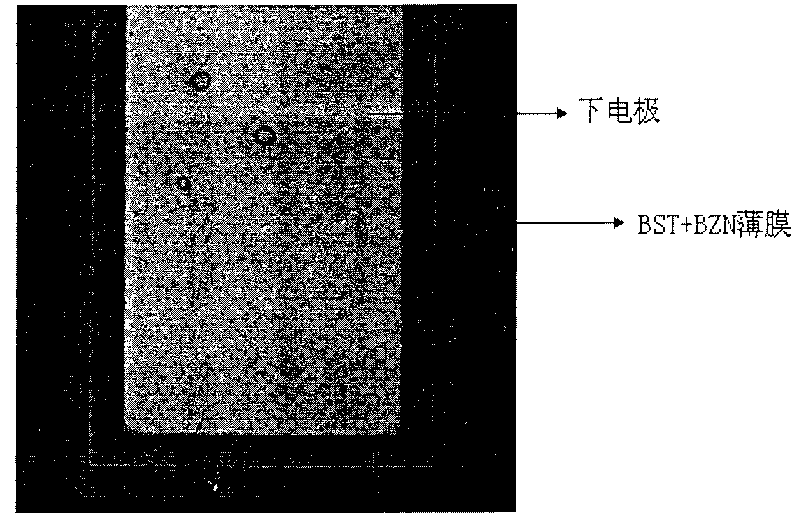

[0030] A manufacturing method of barium strontium titanate (BST) and bismuth zinc niobate (BZN) composite film, the main steps are as follows: firstly prepare HF / HNO according to a certain proportion 3 / CA / H 2 O and HF / HCl / H 2 O etching solution; then the BST+BZN composite thin film samples were etched in two etching solutions respectively. After etching, there must be insoluble reactants remaining on the lower surface substrate and the steps between the lower electrode metal and the substrate. And the film under the photoresist mask will be etched to a certain extent; then the photoresist is removed with acetone / ethanol, and the photoresist mask is re-prepared; then the BST+BZN film sample is etched in HF / HNO 3 / CA / H 2 Perform low-power ultrasonic treatment in O etching solution to remove residual substances; finally remove photoresist with acetone / et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com