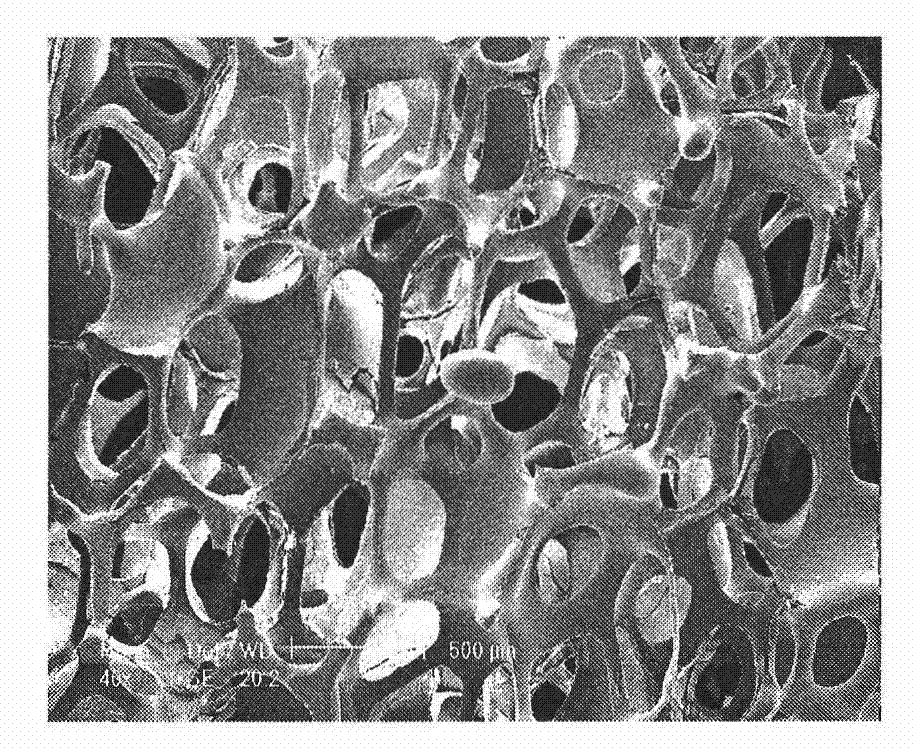

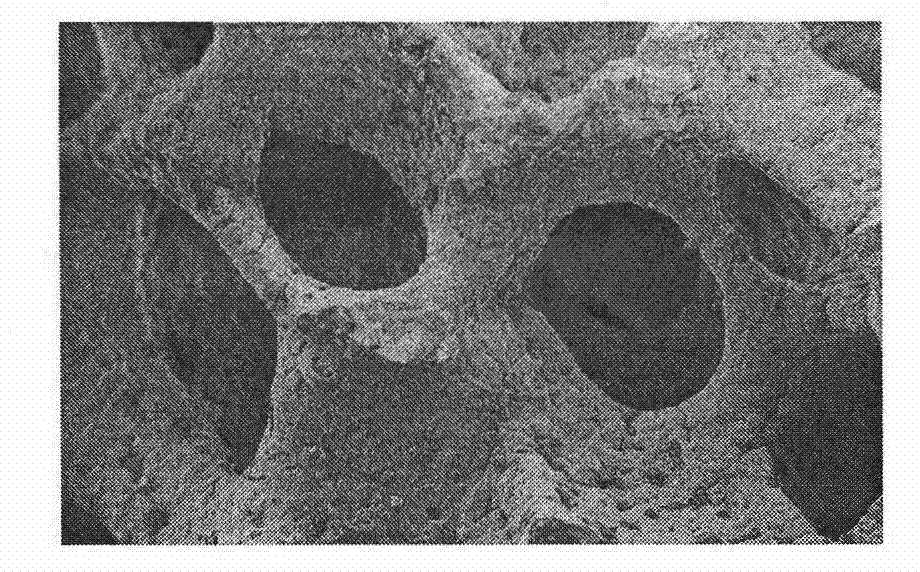

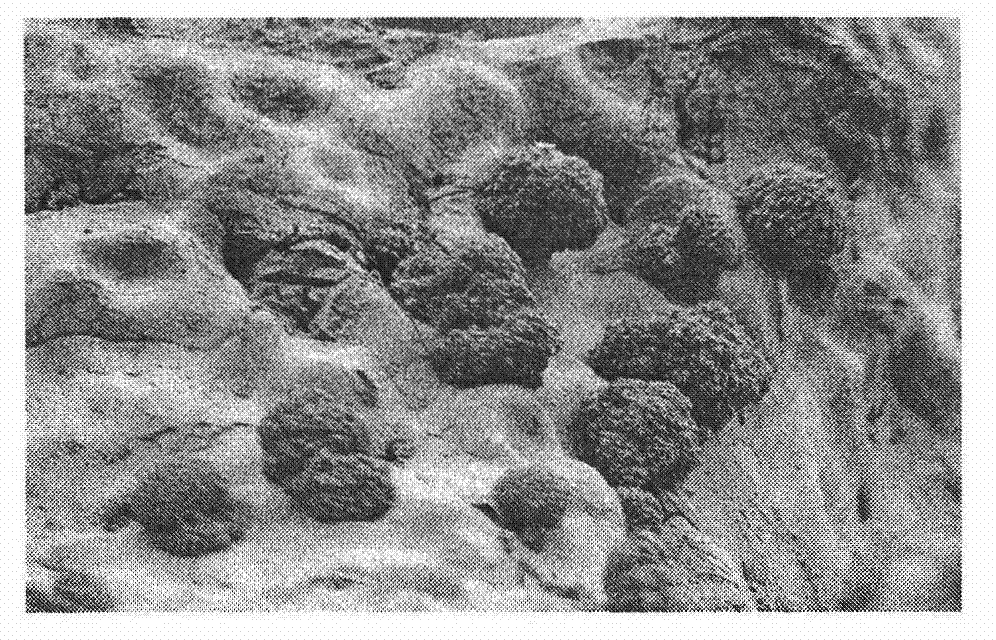

High-intensity porous bone repair material and method for preparing same

A technology for repairing materials and porous bone, applied in medical science, prosthesis, etc., can solve problems such as restricting the application of bone repair materials, and achieve the effect of improving contradictions, expanding the scope of application, and good pore penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of bioglass:

[0029] (1) will P 2 o 5 , CaO, Na 2 Grind O and MgO according to the mass ratio of 62:10:15:5.30, grind and mix evenly, add deionized water slowly, stir until no bubbles emerge, and melt at 940°C for 1.5 hours after drying to obtain a milky white block objects, ground into powder;

[0030] (2) Carry out the following heat treatment to the powder: keep warm at 710°C for half an hour, cool to room temperature; keep warm at 745°C for 1 hour, then keep warm at 800°C for 2 hours, and cool with the furnace. bioglass of magnesium salts;

[0031] (3) Add the bioglass whose composition is sodium pyrophosphate and sodium calcium magnesium salt into deionized water, stir constantly, remove the supernatant liquid in the container, repeat several times until the pH of the solution is 8.5, and then a kind of biological glass is made. Glass.

Embodiment 2

[0033] Preparation of bioglass:

[0034] (1) will P 2 o 5 , CaO, Na 2 O and MgO, according to the mass ratio of 41.4:9.8:18:4, grind and mix evenly, slowly add deionized water, stir until no bubbles come out, melt at 980°C for 1 hour after drying, and obtain a milky white block objects, ground into powder;

[0035] (2) Carry out the following heat treatment to the powder: keep warm at 710°C for half an hour, cool to room temperature; keep warm at 740°C for 1 hour, then keep warm at 800°C for 2 hours, and cool with the furnace. The resulting ingredients are sodium pyrophosphate and sodium calcium acid bioglass of magnesium salts;

[0036] (3) Add the bioglass whose composition is sodium pyrophosphate and sodium calcium magnesium salt into deionized water, stir continuously, remove the supernatant liquid in the container, repeat several times until the pH of the solution is 7, and then a kind of biological glass is made. Glass.

Embodiment 3

[0038] Preparation of bioglass:

[0039] (1) will P 2 o 5 , CaO, Na 2 O and MgO, according to the mass ratio of 50:13:12:3.50, grind and mix evenly, add deionized water slowly, stir until no bubbles come out, dry and melt at 900°C for 2 hours to obtain a milky white block objects, ground into powder;

[0040] (2) Carry out the following heat treatment to the powder: keep warm at 720°C for half an hour, cool to room temperature; keep warm at 750°C for 1 hour, then keep warm at 800°C for 2 hours, and cool with the furnace. The resulting ingredients are sodium pyrophosphate and sodium calcium acid bioglass of magnesium salts;

[0041] (3) Add the bioglass whose composition is sodium pyrophosphate and sodium calcium magnesium salt into deionized water, stir constantly, remove the supernatant liquid in the container, repeat several times until the pH of the solution is 8, that is, a biological glass is made. Glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com