Method for synthesizing lithium ferrous phosphate in solution

A lithium ferrous phosphate solution technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of harsh liquid phase control conditions, and avoid product impurity, low energy consumption, ions and electrons The effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

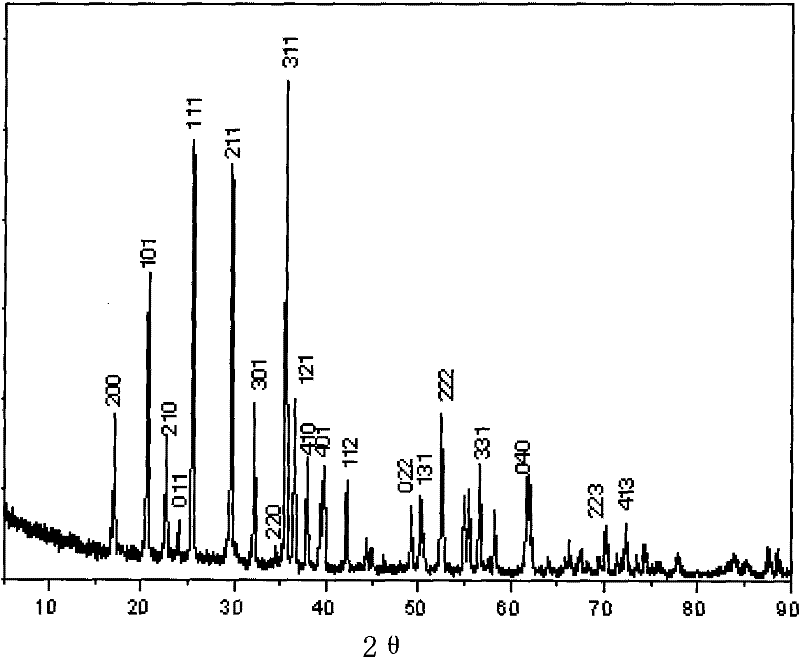

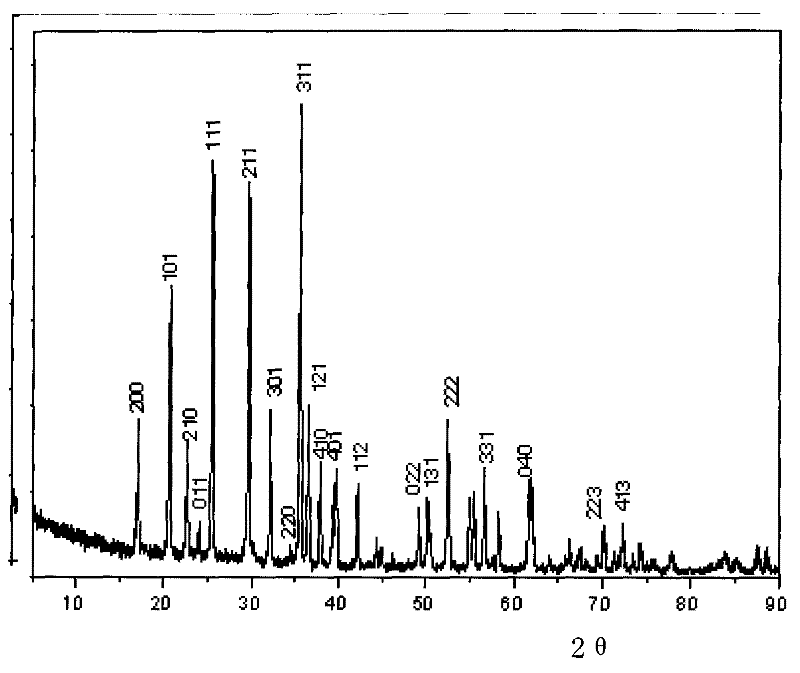

Image

Examples

specific Embodiment approach

[0029] 1) Under the protection of 1-10L / mim N2, mix 0.1mol phosphoric acid and ferric oxide at 70°C for 1 hour; then add reduced iron powder and react for 4 hours; where phosphoric acid: ferric oxide: moles of reduced iron powder Ratio = 3.05:1:1.03.

[0030] 2) Under the protection of N2, add a phenolic resin with a carbon content of 5 wt% in the lithium ferrous phosphate powder material to a lithium hydroxide solution with a concentration of 0.1 mol; react at 90° C. for 4 hours;

[0031] 3) Cool the reaction solution to room temperature, vacuum filter to obtain lithium iron phosphate wet material, and then dry it in a vacuum drying oven at 120°C for 12 hours;

[0032] 4) Under the protection of 1-10L / mim N2, heat in a tube furnace at 200°C for 3h, and sinter at 700°C for 4h to obtain lithium iron phosphate powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com