High-performance base mortar

A mortar and basic technology, applied in the field of high-performance basic mortar, can solve the problems of low measurement accuracy, cracking and falling off, low tensile strength, etc., to protect the environment, promote commercialization, and save energy.

Inactive Publication Date: 2010-04-21

北京艺高世纪科技股份有限公司

View PDF0 Cites 53 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Traditional solid brick wall materials mostly use cement-based mortar, but with the popularization and application of new lightweight wall materials, such as aerated concrete blocks, slag blocks, lime sand bricks, ceramsite bricks, etc., due to the The properties have changed. The thermal conductivity and linear shrinkage of ordinary mortar and these new wall materials are quite different. However, the construction mortar itself prepared by the construction site has large shrinkage and low bond strength due to low measurement accuracy and poor quality stability. Low, low tensile strength, small ultimate elongation, significant brittleness, the mixture does not have enough time to form tensile strength to resist the capillary shrinkage stress due to rapid evaporation under the conditions of sunshine, wind, etc., so the difference causes The stress generated by the thermal expansion and contraction of the new wall material causes large-scale cracking and peeling off of the wall plaster layer of the new wall material after one or two years, which seriously affects the project quality and normal use, and also seriously restricts the application of the new wall material. Popularization and application, but also cause waste of materials and pollution of the construction environment

With the rapid development of the country's urbanization process, the continuous improvement of modern building technology requirements and the urgent need for green environmental protection, traditional mortar has not adapted to the requirements of social development, nor can it meet the needs of diversified mortar varieties.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

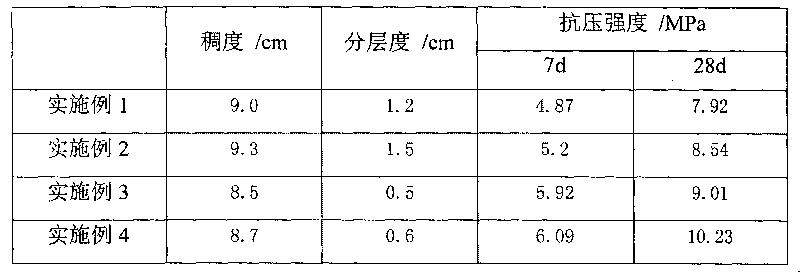

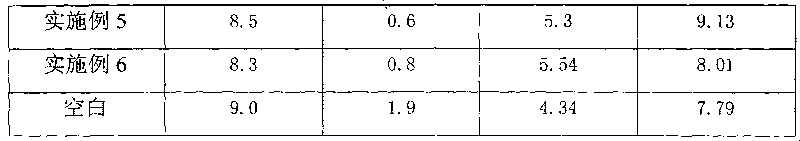

Effect test

Embodiment 2

[0023] raw material

Embodiment 3

[0025] raw material

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention aims at providing a low-cost multipurpose base mortar which comprises the following ingredients in proportions: 15-50 percent of cement, 50-85 percent of sand, 1-20 percent of inorganic composite material, 0.05-10 percent of organic composite material and 0.1-5 percent of fibrous material. The invention generates a super-composition effect by utilizing a multi-compositing design thinking and adding a plurality of inorganic and organic functional materials and enables that the mortar performance is greatly prompted, different types of prepared mortars satisfy the rigorous requirement for the mortar performance from various corresponding novel materials, the cost is not increased remarkably, and factory-produced dry-mixed mortar can be used in engineering construction actually.

Description

technical field [0001] The invention relates to the field of building materials, in particular to a high-performance basic mortar used for building construction through composite modification of organic and inorganic materials. Background technique [0002] Common building mortars widely used are divided into masonry, plastering and ground mortars according to their uses. Traditional solid brick wall materials mostly use cement-based mortar, but with the popularization and application of new lightweight wall materials, such as aerated concrete blocks, slag blocks, lime sand bricks, ceramsite bricks, etc., due to the The properties have changed. The thermal conductivity and linear shrinkage of ordinary mortar and these new wall materials are quite different. However, the construction mortar itself prepared by the construction site has large shrinkage and low bond strength due to low measurement accuracy and poor quality stability. Low, low tensile strength, small ultimate el...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/00C04B28/04C04B28/08C04B14/06

CPCC04B28/08C04B28/04Y02P40/10Y02W30/91C04B7/02C04B7/26C04B14/102C04B14/104C04B14/106C04B14/28C04B14/42C04B16/0625C04B16/0633C04B16/0658C04B18/08C04B18/26C04B22/064C04B24/02C04B24/16C04B24/18C04B24/223C04B24/226C04B24/38C04B24/383

Inventor 田辉宋德强

Owner 北京艺高世纪科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com