Silicon-aluminium aerogel composite material and manufacturing method thereof

A composite material and aerogel technology, applied in the field of materials, can solve the problems affecting high temperature thermal insulation performance, high temperature structural instability, etc., and achieve the effects of excellent mechanical properties, excellent thermal insulation performance, and low and high temperature thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

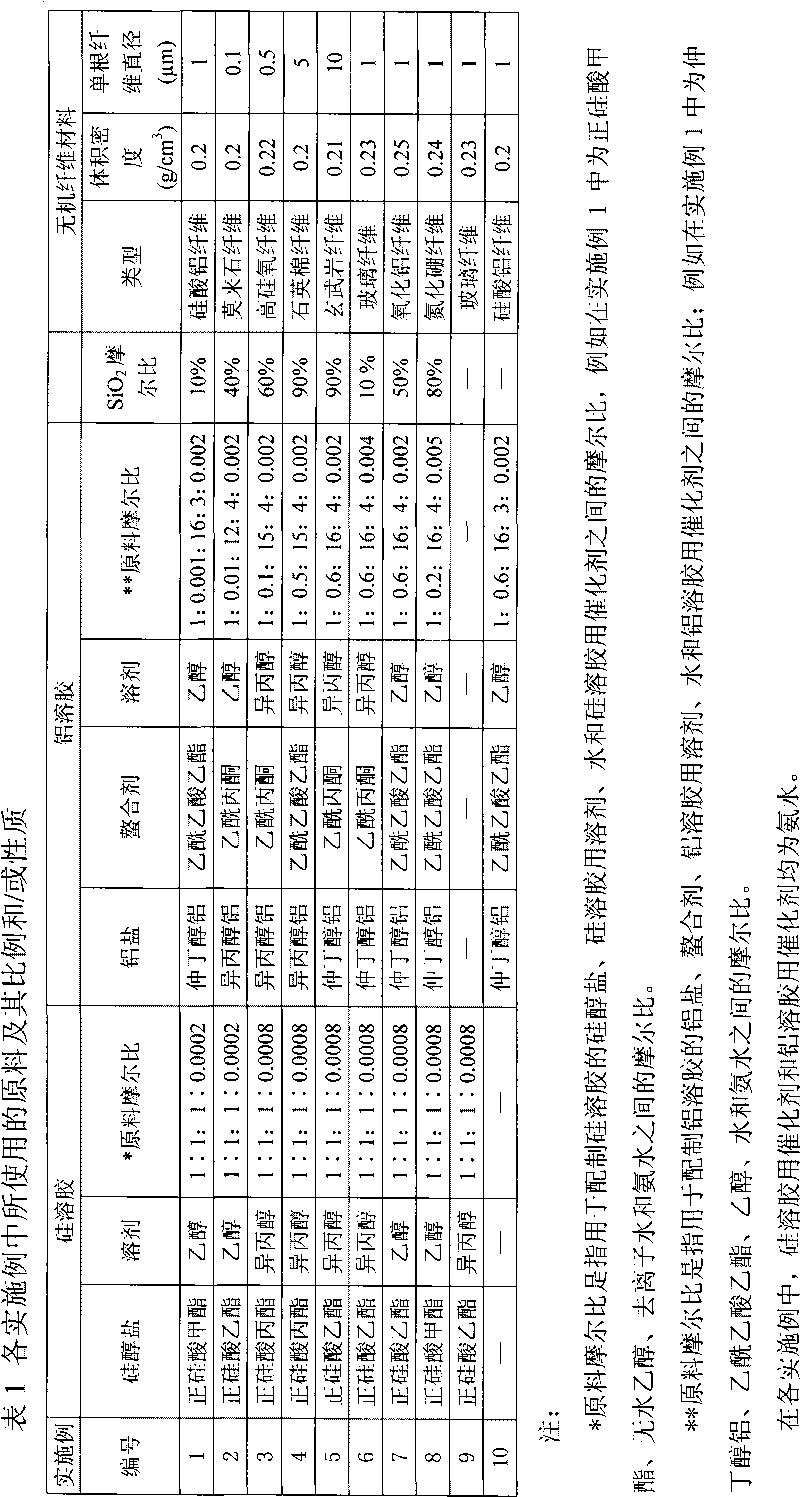

[0051] (1) Preparation of silica sol: silica sol is formulated with silicon alkoxide, solvent for silica sol, catalyst for silica sol and water;

[0052] (2) Preparation of aluminum sol: aluminum salt, chelating agent, solvent for aluminum sol and catalyst and water for aluminum sol are mixed with aluminum sol;

[0053] (3) Preparation of silicon-aluminum composite sol: mix the silica sol and the aluminum sol uniformly to obtain the silicon-aluminum composite sol, preferably, according to making the SiO in the silicon-aluminum composite aerogel 2 Mixing the silica sol and the aluminum sol in a ratio of 0.01% to 100% based on the moles of the silicon-aluminum composite airgel;

[0054] (4) Dipping: the silicon-aluminum composite sol is immersed in the inorganic fiber material through an impregnation process to obtain a mixture of the silicon-aluminum composite sol and the inorganic fiber material;

[0055] (5) Gelling: the mixture obtained in step (4) is placed in an environme...

Embodiment 1

[0083] The silica-alumina airgel composite material prepared in this example is an aluminum silicate fiber reinforced silica-alumina airgel composite material, and the SiO in the silica-alumina composite airgel 2 The molar ratio relative to the silicon-aluminum composite airgel is 10%. The silica sol is prepared under the following conditions: methyl orthosilicate, absolute ethanol, deionized water, and ammonia water in a molar ratio of 1:1:1:0.0002, and a basic catalyst to form a silica sol. The preparation conditions of the aluminum sol are that the molar ratio of aluminum sec-butoxide, ethyl acetoacetate, ethanol, water and ammonia water is 1: 0.001: 16: 3: 0.002, and the aluminum sol is formulated with a basic catalyst, and then the obtained Silica sol and aluminum sol are mixed evenly to prepare silicon-aluminum composite sol, and the mixing ratio of silica sol and aluminum sol is based on making the SiO in the silicon-aluminum composite airgel 2 The molar ratio relative...

Embodiment 2

[0085] The silicon-aluminum airgel composite material prepared in this embodiment is mullite fiber reinforced silicon-aluminum composite airgel, and the SiO in the silicon-aluminum composite airgel 2 The molar ratio relative to the silicon-aluminum composite airgel is 40%. The silica sol is prepared under the following conditions: tetraethyl orthosilicate, absolute ethanol, deionized water, and ammonia water in a molar ratio of 1:1:1:0.0002, and a basic catalyst to form a silica sol. The preparation conditions of the aluminum sol are that the molar ratio of aluminum isopropoxide, acetylacetone, ethanol, water and ammonia water is 1: 0.01: 12: 4: 0.002, and the aluminum sol is formulated with a basic catalyst, and then the prepared silicon The sol and the aluminum sol are uniformly mixed to prepare the silicon-aluminum composite sol. Directly add the silica-alumina composite sol to the container with a bulk density of 0.2g / cm 3 , In the mold of mullite fiber with a single fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Linear shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com