Preparation method of alpha-Sialon fluorescent powder

A technology of alpha-sialon and fluorescent powder, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of low color rendering index, long synthesis time, high temperature reaction, etc., and achieve simple equipment, low cost, and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

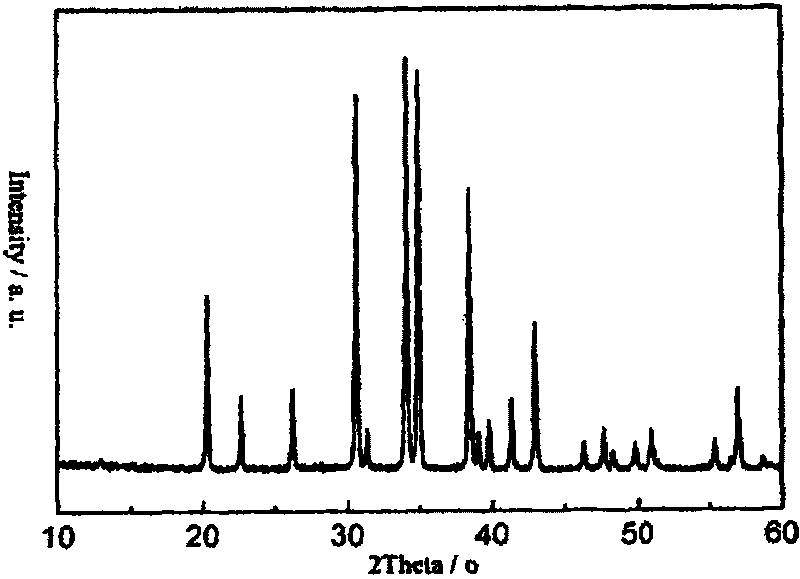

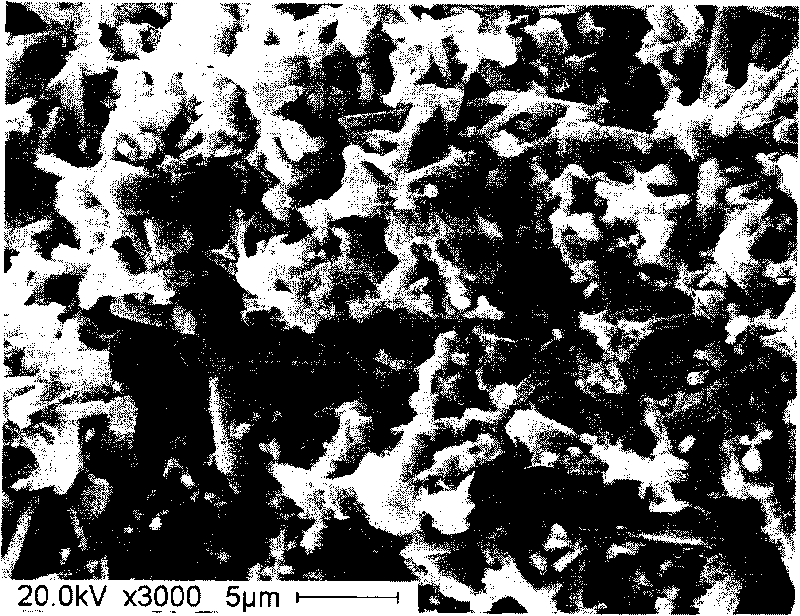

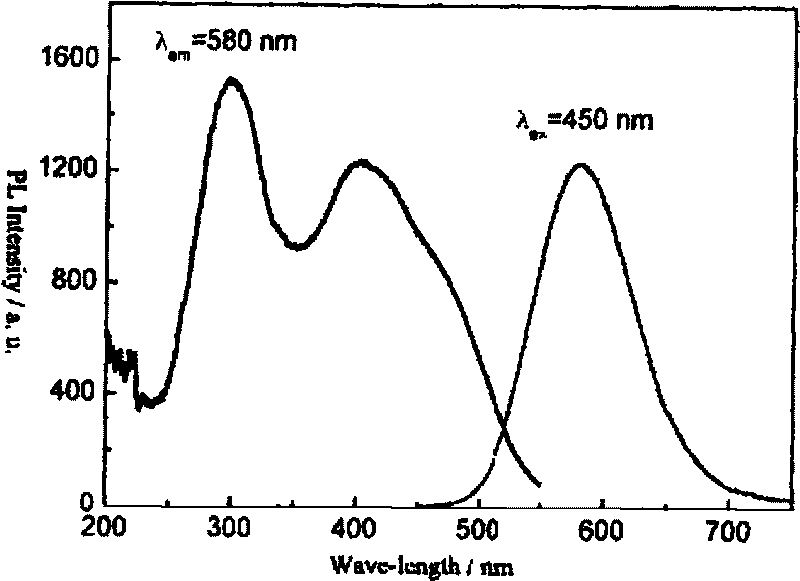

Image

Examples

Embodiment 1

[0026] A preparation method of Alpha-Sialon fluorescent powder, comprising the steps of:

[0027] m 1 Choose Ca and Mg, Ca:Mg=3:1, M 2 Choose Eu; determine: x=0.7, y=0.2, m=2, n=1, the chemical composition of α-Sialon phosphor is Ca 0.525 Mg 0.175 Eu 0.2 Si 9 al 3 ON 15 ; Select the raw material as: CaCO 3 , MgCO 3 、Eu 2 o 3 , silicon powder, aluminum powder and α-Sialon powder, wherein α-Sialon powder accounts for 15% of the total weight of raw materials; the weight ratio of each raw material is calculated as: CaCO 3 : MgCO 3 :Eu 2 o 3 : Silicon powder: Aluminum powder: α-Sialon = 2.1: 0.7: 1.4: 71.1: 9.7: 15; Weigh each raw material in proportion; put the weighed raw material into a ball mill barrel made of silicon oxide, and put nitrogen Silica grinding balls, the ball-to-material ratio is: 3:1, put in absolute ethanol as the dispersion medium, planetary ball milling for 10 hours, the speed is 120 rpm; take out the obtained slurry, after drying, pass through a...

Embodiment 2

[0029] A preparation method of Alpha-Sialon fluorescent powder, comprising the steps of:

[0030] m 1 Choose as Y, M 2 Choose Eu; determine: x=1, y=0.2, m=3.6, n=1.8, the chemical composition of α-Sialon phosphor is YEu 0.2 Si 6.6 al 5.4 o 1.8 N 14.2 ; Select the raw material as: Y 2 o 3 、Eu 2 o 3 , silicon powder, aluminum powder and α-Sialon powder, wherein α-Sialon powder accounts for 10% of the total weight of raw materials; the weight ratio of each raw material is calculated as: Y 2 o 3 :Eu 2 o 3 : Silicon powder: Aluminum powder: α-Sialon = 21.2: 6.6: 34.8: 27.4: 10; Weigh each raw material in proportion; put the weighed raw material into a ball mill barrel made of silicon oxide, and put it into silicon nitride Grinding balls with a ball-to-material ratio of 3:1, put in absolute ethanol as a dispersion medium, planetary ball milling for 12 hours, and the rotation speed is 100 rpm; the obtained slurry is taken out, dried, and passed through a 200-mesh sieve. ...

Embodiment 3

[0032] A preparation method of Alpha-Sialon fluorescent powder, comprising the steps of:

[0033] m 1 Choices are Ca, Y and Gd, M 2 Choose Eu and Yb; determine: x=1, y=0.2, m=3.6, n=1.8, the chemical composition of α-Sialon phosphor is Ca 0.3 Y 0.4 Gd 0.3 Eu 0.1 Yb 0.1 Si 6.6 al 5.4 o 1.8 N 14.2 ; Select the raw material as: CaCO 3 , Y 2 o 3 、Gd 2 o 3 、Eu 2 o 3 , Yb 2 o 3 , silicon powder, aluminum powder and α-Sialon powder, wherein α-Sialon powder accounts for 20% of the total weight of raw materials; the weight ratio of each raw material is calculated as: CaCO 3 : Y 2 o 3 :Gd 2 o 3 :Eu 2 o 3 :Yb 2 o 3 : silicon powder: aluminum powder: α-Sialon = 4.8: 7.2: 8.7: 2.8: 3.2: 29.8: 23.5: 20; Weigh each raw material in proportion; put the weighed raw material into a ball mill barrel made of silicon oxide , put silicon nitride grinding balls, the ball-to-material ratio is: 3:1, put in absolute ethanol as the dispersion medium, planetary ball mill for 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com