Method for preparing black berry wine by combing yeast deacidification technology with ultrahigh pressure processing technology

A processing technology and ultra-high pressure technology, applied in the field of brewing industry, can solve the problems of damage of nutrients, loss of volatile aroma, intensified discoloration, etc., and achieve the effects of increasing the content of flavor substances, prolonging the shelf life and simplifying the production steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

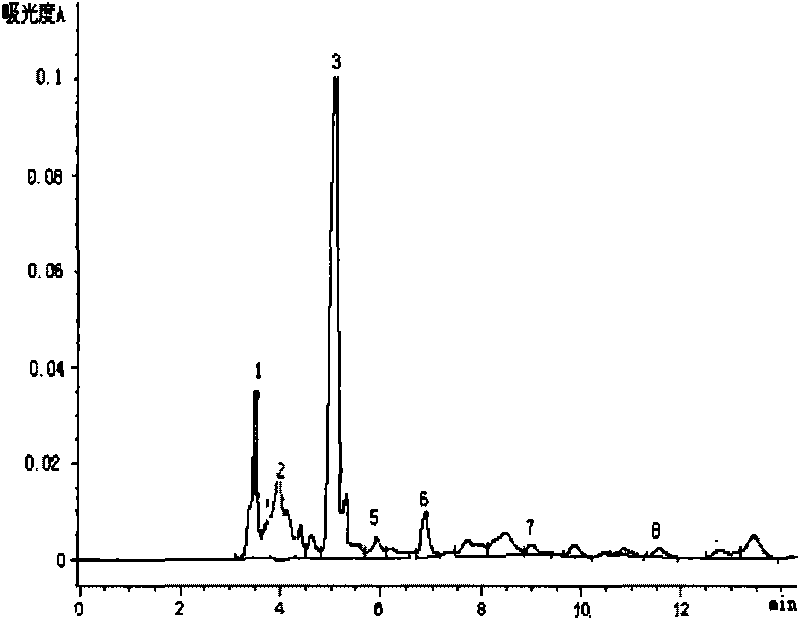

Embodiment 1

[0030] The blackberry frozen fruit of Boysen variety was naturally thawed at room temperature, then beaten, and the pomace was separated. After measuring the sugar content Y (unit: g / L) of the juice and the volume V (unit: L) of the blackberry juice, according to the target alcohol content of 12 degrees, Calculate the amount of added sugar (grams) X=(17×12-Y)×V. Add fruit pomace when melting sugar, keep at 100°C for half an hour for sugar melting and hot leaching, cool the melted sugar residue mixture to about 50°C, add it to the fermentation container, and mix it with blackberry juice evenly, according to the volume ratio Add 0.01% low-temperature acid pectinase and 0.025% acid-reducing yeast (Saccharomyces cerevisiae). Before the yeast is added to the fermentation vessel, it needs to be activated with 180g / L sugar solution at 35°C for 2 hours. When fermented at 20°C to a residual sugar of 4g / L, filter and remove the slag to obtain raw wine, and adjust its alcohol content and...

Embodiment 2

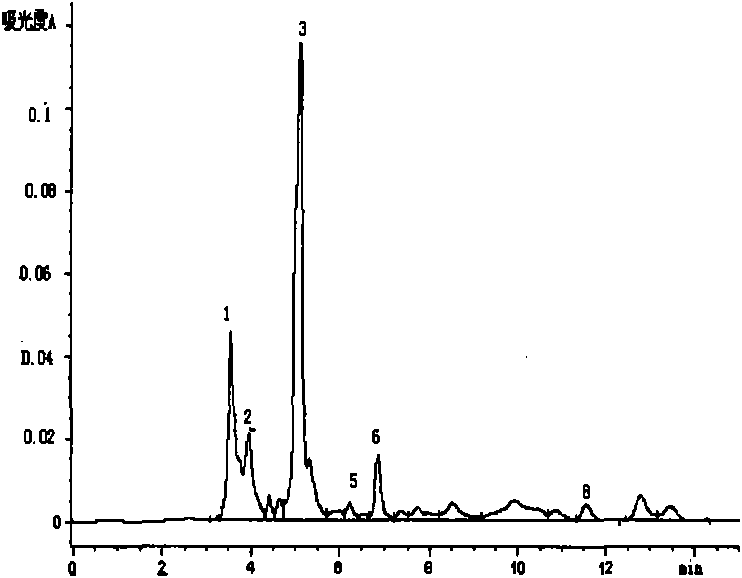

[0034] The preparation method of blackberry wine fermented liquid, low-temperature acid pectinase addition, fermentation conditions and ultra-high pressure treatment are all the same as in Example 1. The acid-reduced yeast, ie Saccharomyces cerevisiae, is added in an amount of 0.03% of the volume of the fermentation broth. The results of sensory evaluation and acidity measurement of the prepared blackberry wine are shown in Table 2.

Embodiment 3

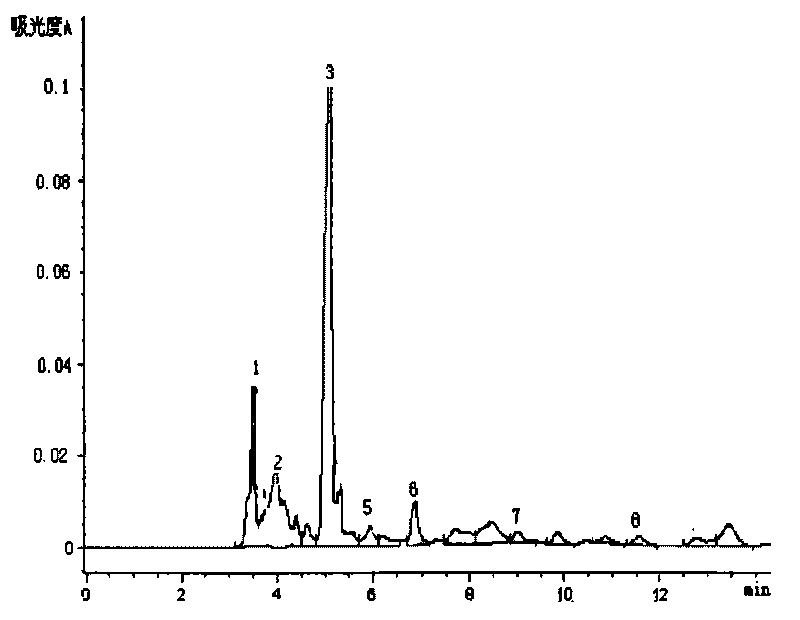

[0036] The preparation method of blackberry wine fermentation liquid, the amount of acid-reducing yeast (Saccharomyces cerevisiae) added, fermentation conditions and ultra-high pressure treatment are all the same as in Example 1. The added amount of the low-temperature acid pectinase is 0.02% of the volume of the fermentation broth. The results of sensory evaluation and acidity measurement of the prepared blackberry wine are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com