Process for smelting tin-lead alloy by tin enriched slag reduction and reduction-smelting reflecting furnace

A technology of tin-lead alloy and tin slag, which is applied to the improvement of process efficiency, lighting and heating equipment, etc., can solve the problems of many processes, high production cost, and difficult to completely separate lead and tin, and achieve high heat utilization rate and low coal consumption. Low, good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

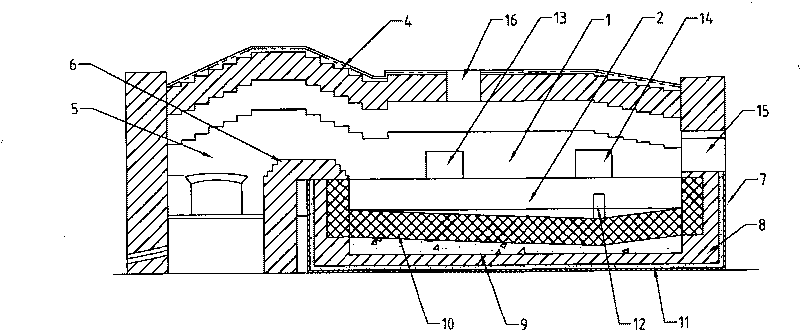

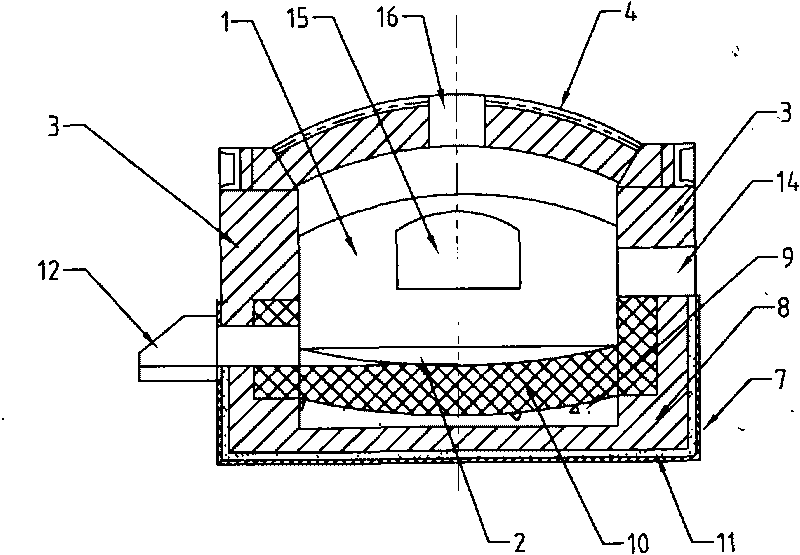

[0037] The present invention will be described in detail below with specific embodiments in conjunction with the accompanying drawings.

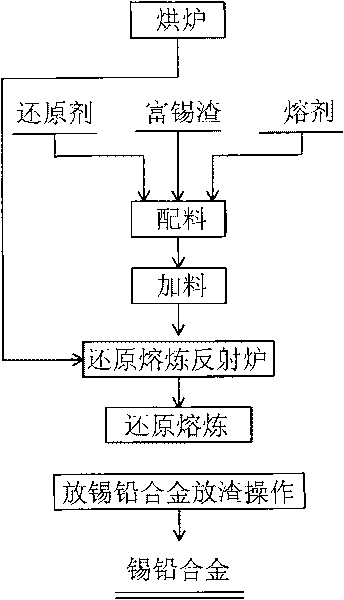

[0038] A tin-rich slag reduction smelting process for tin-lead alloys adopts discontinuous smelting operations and is carried out in batches; it includes ovens, batching, feeding, reduction smelting and tin-lead alloy slag discharge operations, see the attached figure 1 As shown, the specific steps are as follows:

[0039] ① Oven

[0040] The oven should be baked in strict accordance with the method of low fire first, then high fire, and slow heating. When the furnace temperature rises, the pull rod should be adjusted to make the tightness of the rebar sleeve fixing the refractory material on the surface of the furnace body suitable; baking 6~ After 10 hours, gradually lower the temperature of the furnace to normal temperature; at this time, also adjust the tie rods to make the tightness of the rebar cover for fixing the refractory material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com