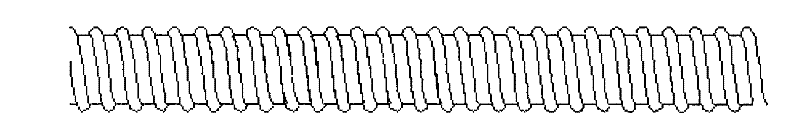

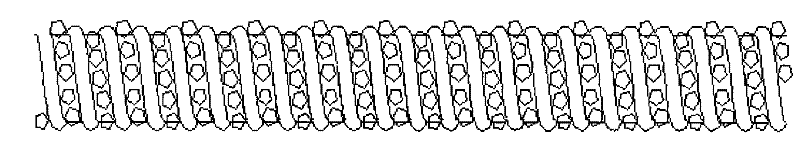

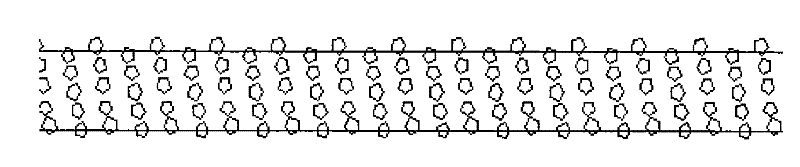

Brazing diamond fret saw with grinding materials being arranged in order in spiral shape and manufacturing process thereof

A diamond wire saw and a manufacturing process technology, applied in the field of abrasives manufacturing, can solve the problems of short life of the wire saw, easy falling off of abrasives, easy blocking and slipping of the wire saw, etc., and achieve long cutting life, high holding strength, and space for chips big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The brazed diamond wire saw of the present invention comprises a steel wire as a base, a brazing metal bond as an intermediate connection layer, and a diamond abrasive directly fixed by the brazing metal bond as an outer layer. Wire saws are used for cutting materials, and the substrate should be able to withstand tensile stress, alternating bending stress and grinding temperature. Therefore, the material of the matrix should have high tensile strength, high bending fatigue strength and high high-temperature mechanical properties. When brazing abrasives, the matrix itself should not experience significant performance attenuation when it is subjected to high temperature. Typical metal matrix materials Including iron, molybdenum, tungsten, and alloys containing any of them. When steel is subjected to brazing high temperature, the tensile strength will be significantly reduced. When the diameter is thicker, it is a feasible material. High carbon steel is relatively less aff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com