Aluminium electrolysis bath

An aluminum electrolytic cell and electrolytic cell technology, which is applied in the field of aluminum electrolytic cells, can solve the problems of low energy utilization rate, large floor space, and short service life, and achieve the effects of high energy utilization rate, small floor space and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

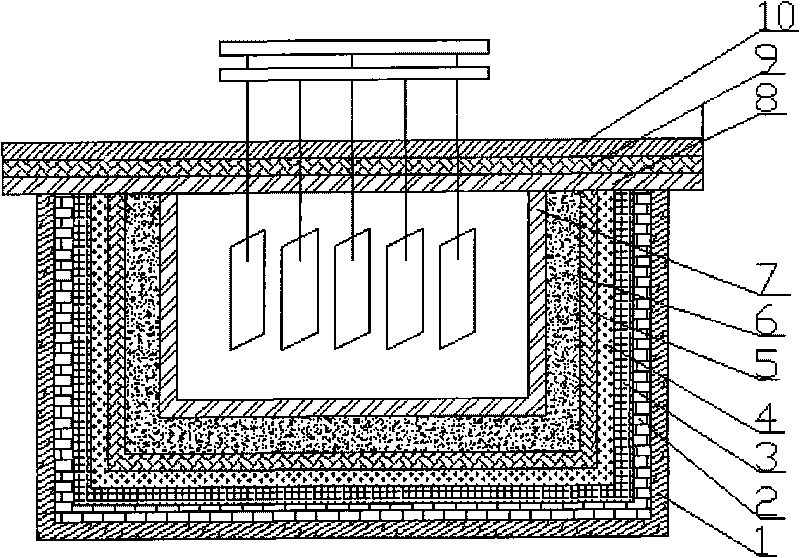

[0045] An aluminum electrolytic cell, the structure of the horizontal cell bottom and the vertical side cell wall of the electrolytic cell sequentially includes: a calcium silicate board layer 1, a light insulation brick layer 2, a refractory brick 3, an anti-seepage material layer 4, silicon Alumina fiber paper layer 5, alumina layer 6, silicon carbide brick or corundum brick or high alumina ceramic brick layer 7; aluminum electrolytic cell cover plate structure consists of corundum plate or high alumina ceramic plate or silicon carbide plate layer from bottom to top 8. Aluminum silicate fiber board layer 9. High alumina cement prefabricated board layer 10. see figure 1 .

Embodiment 2

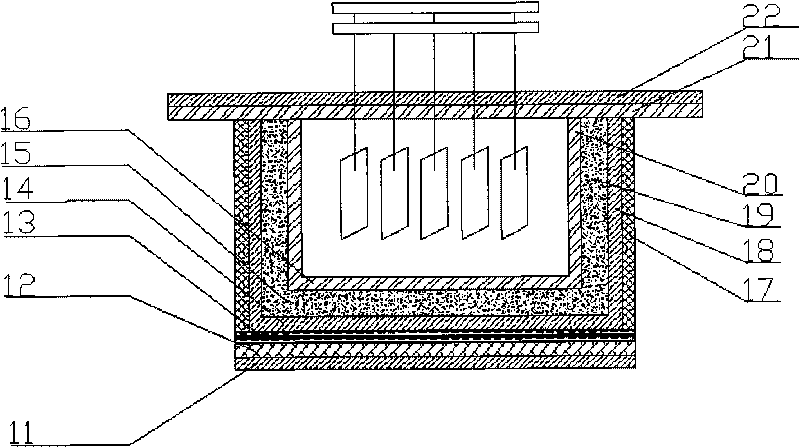

[0047] An aluminum electrolytic cell, the structural composition of the horizontal cell bottom of the electrolytic cell sequentially includes a calcium silicate board layer 11, an insulating brick layer 12, an anti-seepage material layer 13, a calcium silicate fiber paper layer 14, and an aluminum oxide layer 15 from outside to inside and high-alumina ceramic brick layer 16; the structure of the vertical side tank wall includes refractory brick layer 17, aluminum silicate fiber paper layer 18, alumina layer 19 and high-alumina ceramic plate layer 20 from outside to inside; aluminum electrolytic cell cover plate The structural composition includes a corundum plate layer 21 at the bottom layer and an aluminum silicate fiber plate layer 22 compounded with the corundum plate layer. see figure 2 .

Embodiment 3

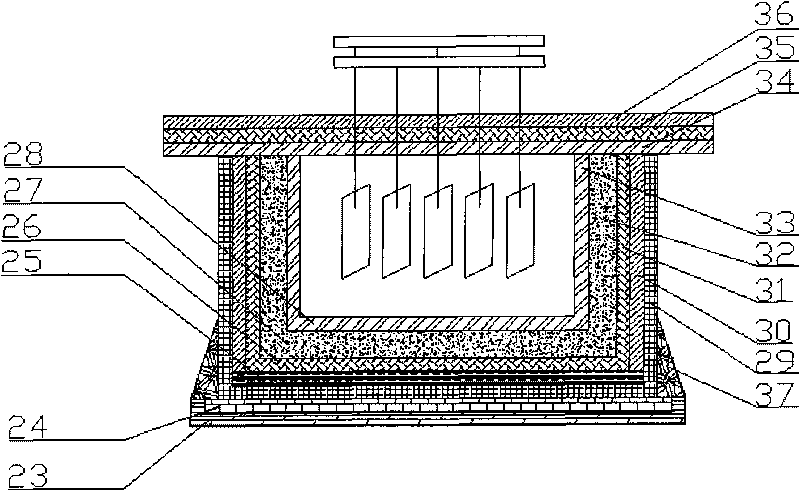

[0049] An aluminum electrolytic cell, the structure of the horizontal cell bottom of the electrolytic cell includes a calcium silicate board layer 23, an insulating brick layer 24, an anti-seepage material layer 25, a calcium silicate fiber paper layer 26, and an aluminum oxide layer 27 from outside to inside. and silicon carbide brick layer 28; the structure of the vertical side groove wall includes refractory brick layer 29, aluminum silicate fiber paper layer 30, high alumina ceramic plate layer 31, aluminum oxide layer 32 and silicon carbide-silicon nitride The plate layer 33; the structure of the cover plate of the aluminum electrolytic cell consists of high alumina ceramic plate layer 34, high alumina cement prefabricated plate layer 35 and aluminum silicate fiber plate layer 36 from bottom to top; Cement castable angular reinforcement 37 . see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com