Micro optical fiber biosensor for detecting nitric oxide concentration in organism

A biosensor, nitric oxide technology, applied in the field of biological detection and clinical medical detection, can solve the problems of difficult optical fiber processing, delicate structure, hard silica material, etc. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

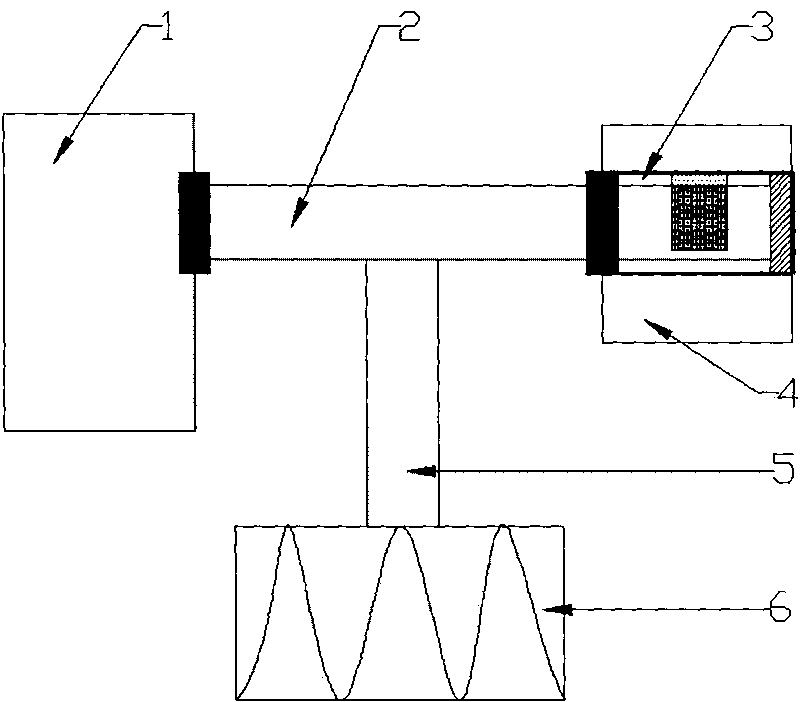

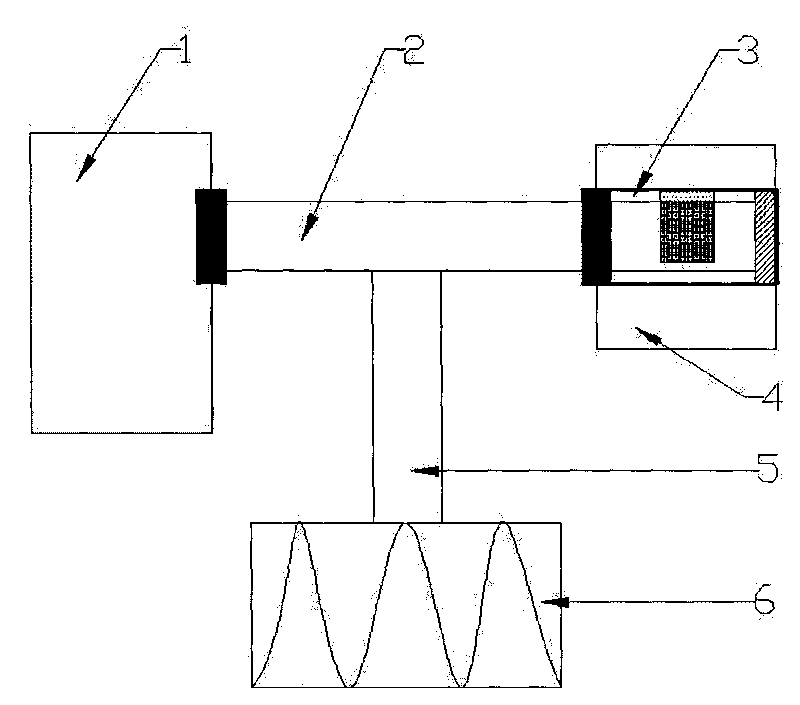

Method used

Image

Examples

Embodiment 1

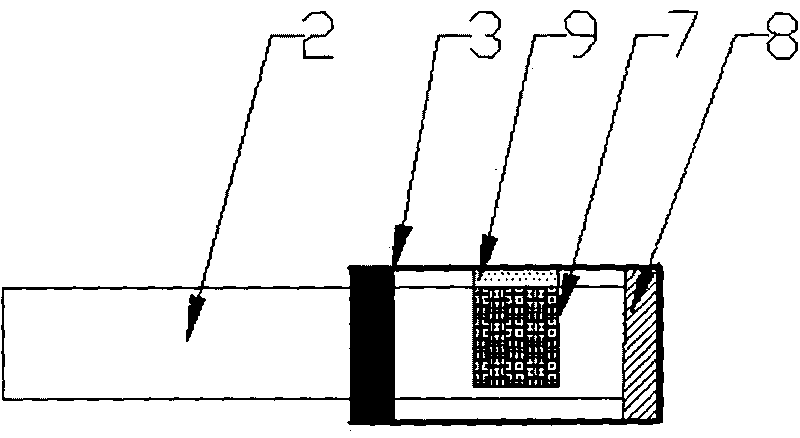

[0024] 1) Using a 157nm deep ultraviolet laser direct etching process to etch microgrooves on the multimode silica fiber, the etched microgrooves have a width of 20-40 μm and a groove length of about 100-120 μm. A Ag film is deposited on the end face of the fiber optic probe to form a reflective film by vacuum evaporation.

[0025] 2) Weigh 0.1g of cellulose acetate and dissolve it in 3.5mL of acetone, seal and stir for 2h, then add 0.25mL of diaminofluoresceins (DAFs) with a concentration of 0.5mmol / ml and 0.5ml of double distilled water to the mixture, and then seal Stir for 6 hours; pour the evenly stirred mixture into a glass biochemical culture dish with a diameter of Φ60 mm, seal the dish with plastic wrap, make holes of appropriate size and number on the plastic wrap, and place it on a horizontal platform at room temperature until the acetone is completely Volatile film can be.

[0026] 3) The NO-sensitive membrane prepared in step 2) is fixed in the optical fiber micr...

Embodiment 2

[0029] Except for replacing the NO fluorescent indicator, other implementation methods are the same as in Example 1.

[0030]Preparation of NO sensitive film: Weigh 0.1g of cellulose acetate and dissolve it in 3.5mL of acetone, and stir for 2h in a closed manner, then add 0.25mL of diaminorhodamines (DARs) with a concentration of 0.5mmol / ml and 0.5ml of double-distilled water, and then airtightly stir for 6 hours; pour the evenly stirred mixture into a glass biochemical culture dish with a diameter of Φ60mm, seal the dish with plastic wrap, make holes of appropriate size and number on the plastic wrap, and place it on a horizontal platform at room temperature Up until the acetone is completely volatilized to form a film.

Embodiment 3

[0032] 1) Using a 157nm deep ultraviolet laser direct etching process to etch microgrooves on the multimode silica optical fiber, the width of the etched microgrooves is about 20-40 μm, and the groove length is about 100-120 μm. The end face of the optical fiber probe is coated with Ag film by vacuum evaporation method to form a reflective film.

[0033] 2) Weigh 0.1g of cellulose acetate and dissolve it in 3.5mL of acetone, seal and stir for 2h, then add 0.25mL of diaminofluoresceins (DAFs) with a concentration of 0.5mmol / ml and 0.5ml of double distilled water to the mixture, and then seal Stir for 6 hours; absorb the evenly stirred mixture and drop it directly into the microgroove of the optical fiber probe described in 1), seal the probe with plastic wrap, and place it on a horizontal platform at room temperature until the acetone is completely volatilized to form a film.

[0034] 3) The optical fiber probe is packaged with a metal sleeve, and the micro-groove structure of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com