Method for preparing magnetic material taking leopard palm as matrix

A magnetic material, konjac technology, applied in the field of functional inorganic materials and nanoscience, can solve the problems of less research on nanomaterials, and achieve the effect of safe preparation process, good soft magnetic material properties, and environmental protection requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of the magnetic material of konjac substrate, it comprises the steps:

[0028] 1) get the ferrous salt and the nickel salt that the total molar number is 5mmol, wherein the molar percentage of the ferrous salt and the total molar number of the nickel salt is 20% (that is, the molar number of the ferrous salt is 1mmol), the The ferrous salt is F e SO 4 , the nickel salt is NiCl 2 ; Konjac 0.3g, water 50mL, hydrazine hydrate 20mL (ie 20.6g);

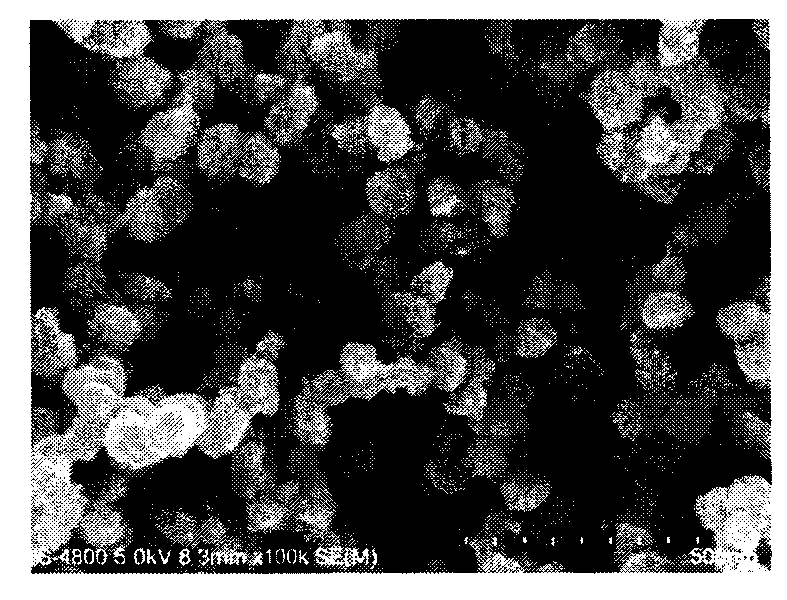

[0029] Mix ferrous salt, nickel salt, konjac and water, stir and disperse for 30 minutes, add hydrazine hydrate (strong reducing agent) at 80°C, stir and react for 30 minutes under alkaline conditions (adjust pH to 10 with NaOH), cool to room temperature, Magnetic separation, separation and washing with water and absolute ethanol were carried out three times respectively, and vacuum drying was carried out at room temperature to obtain FeNi magnetic nanoparticles synthesized with konjac as a template. ...

Embodiment 2

[0035] A kind of preparation method of the magnetic material of konjac substrate, it comprises the steps:

[0036] Step 1) is identical with embodiment 1.

[0037] 2) FeNi magnetic nanoparticles and konjac are added to water to obtain a mixed solution; the mass concentration of FeNi magnetic nanoparticles in the mixed solution is 0.7wt%, and the mass concentration of konjac in the mixed solution is 12.5wt%; Stir for 60 minutes, cool to room temperature, pour into a mold, transfer to an oven and dry at 80° C. for 10 hours to obtain a konjac-based magnetic material.

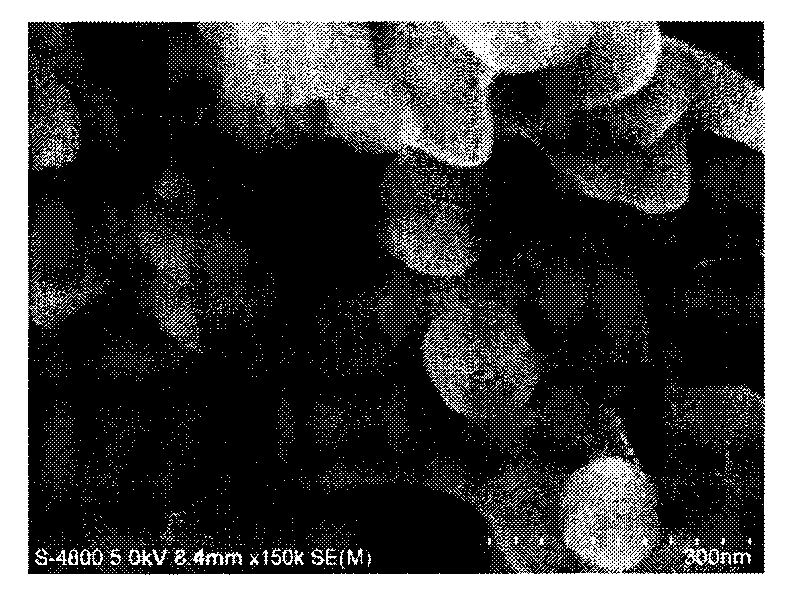

[0038] Figure 8 The FESEM figure of the magnetic membrane material of the konjac substrate synthesized by this embodiment is shown, Figure 8 It can be seen that the surface of the product is smooth as a whole, containing a small amount of small protrusion structures, and a large number of pore-like structures of about 30 nm are distributed in it.

Embodiment 3

[0040] A kind of preparation method of the magnetic material of konjac substrate, it comprises the steps:

[0041] Step 1) is identical with embodiment 1.

[0042] 2) FeNi magnetic nanoparticles and konjac are added to water to obtain a mixed solution; the mass concentration of FeNi magnetic nanoparticles in the mixed solution is 0.7wt%, and the mass concentration of konjac in the mixed solution is 15wt%; the mixed solution is stirred at 80°C After 60 minutes, cool to room temperature, pour into a mold, transfer to an oven and dry at 80° C. for 10 hours to obtain a konjac-based magnetic material.

[0043] Figure 9 The FESEM figure of the magnetic membrane material of the konjac substrate synthesized by this embodiment is shown, Figure 9 It can be seen that the surface of the product is uneven and concave-convex.

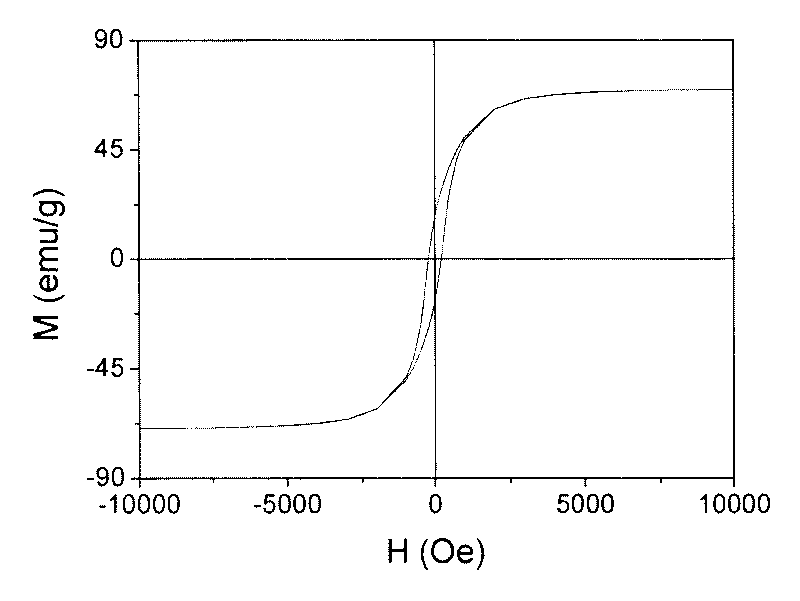

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com