Preparation method of composite cathode material of lithium iron phosphate and carbon nano-tubes

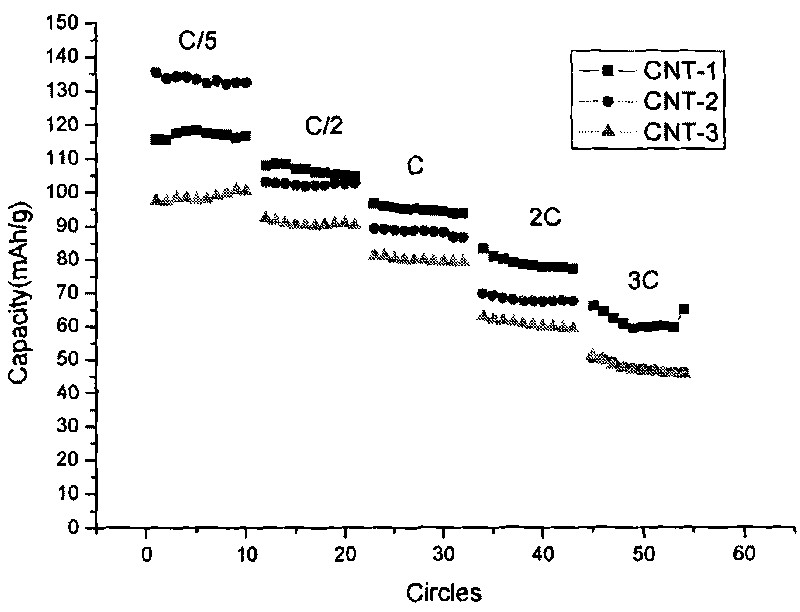

A carbon nanotube composite and lithium iron phosphate technology, which is applied in battery electrodes, electrical components, circuits, etc., can solve the problems of low lithium ion diffusion speed and low conductivity of pure lithium iron phosphate, and achieve improved contact and strengthened conductive network , Improve the effect of electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preparation method of lithium iron phosphate and carbon nanotube composite cathode material comprises the following steps:

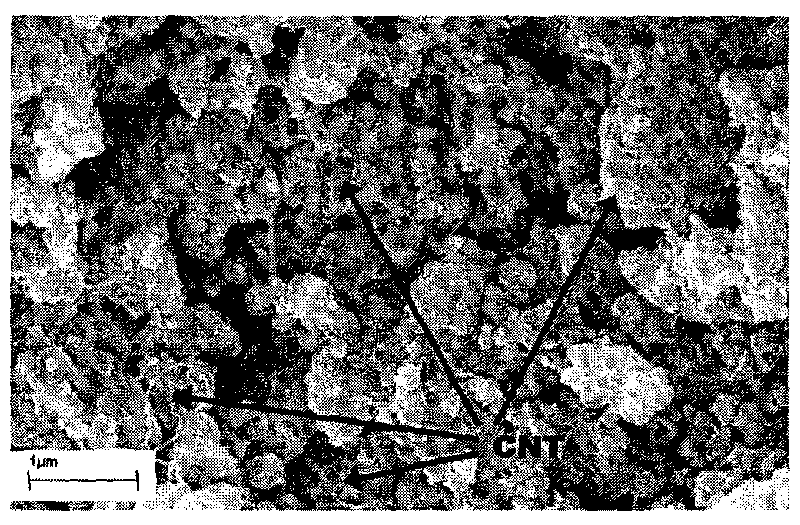

[0016] 1) Impurities in nanotubes mainly include amorphous carbon, iron, etc., so they need to be purified before use: heat carbon nanotubes in 4M nitric acid at 80°C for about 6 hours, and then undergo ultrasonication, filtration, and repeated cleaning until they are cleaned The pH value of the liquid is about 5.8;

[0017] 2) Prepare the precursor with citric acid, lithium nitrate, iron nitrate and ammonium dihydrogen phosphate as reactants. The specific process is: dissolve citric acid in an appropriate amount of deionized water, heat and stir at 80-90°C, and then add lithium nitrate and nitric acid in sequence The aqueous solution of iron and ammonium diammonium phosphate, the solution is brown and transparent, and the precursor is obtained;

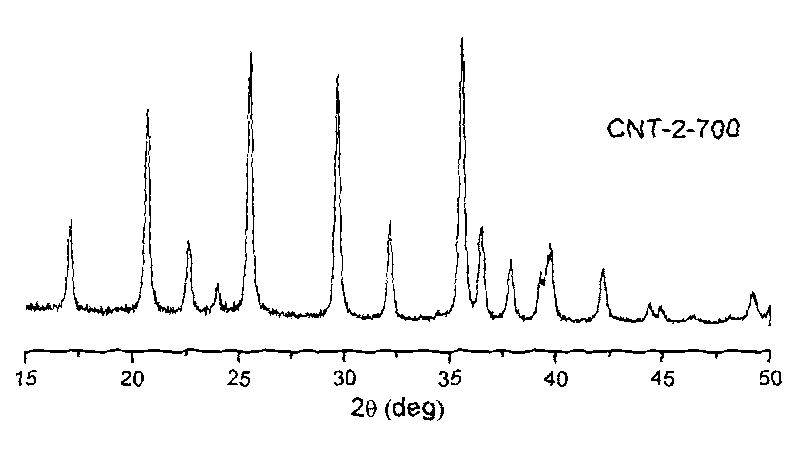

[0018] 3) Take the above three parts of the same precursor, add carbon nanotubes to the precurso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com