Non-annular cavity type semiconductor laser

A ring cavity and semiconductor technology, used in semiconductor lasers, lasers, laser parts, etc., can solve the problems of reducing the electro-optical conversion efficiency of laser devices, reducing the optical output power of the device, and increasing the lasing threshold of the laser device. Conversion efficiency, the effect of improving optical output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

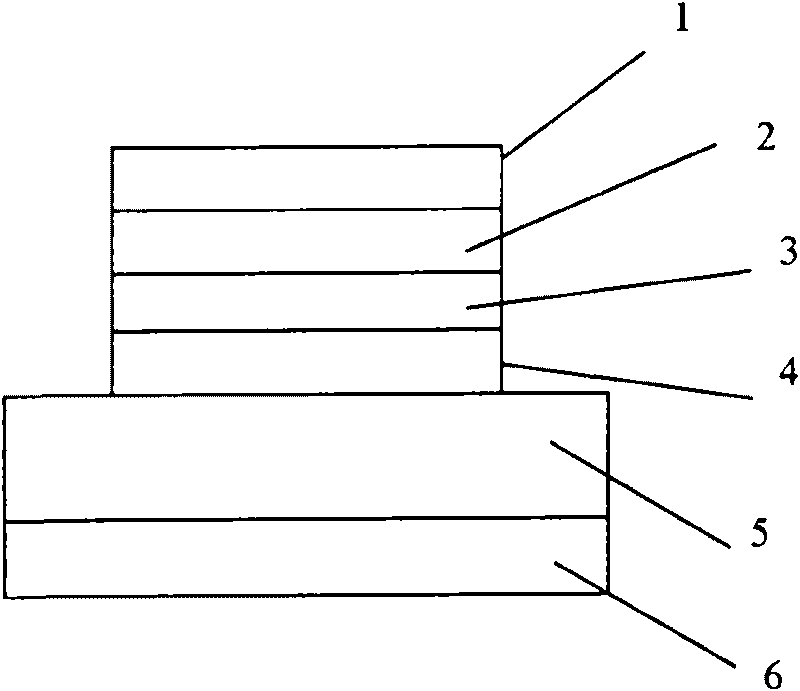

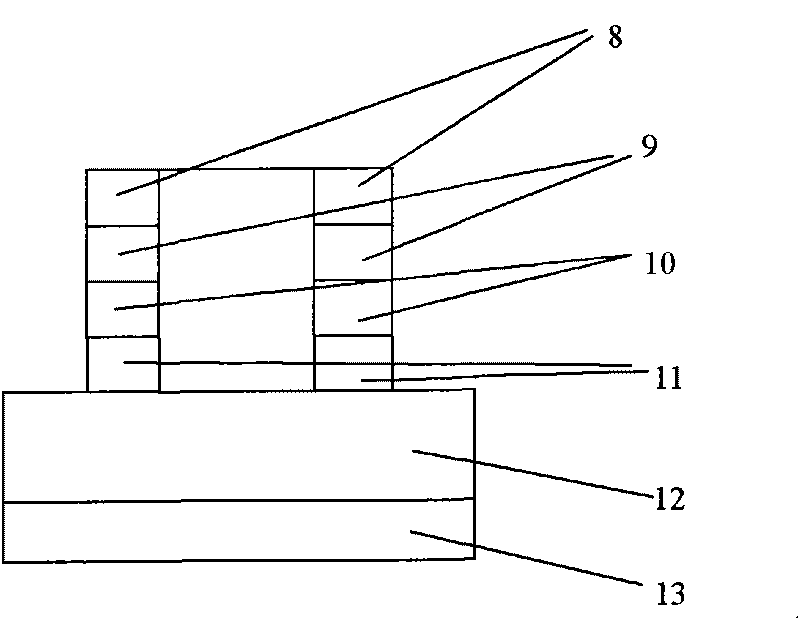

[0016] Such as Figure 3-4 As shown, the upper electrode 8 of the non-circular ring cavity is a gold electrode, the upper waveguide layer 9 is InGaAsP, the active gain region 10 is an InGaAs / InAlAs quantum well cascade structure, the lower waveguide layer 11 is InGaAsP, and the substrate 12 is InP And the lower electrode 13 is a gold electrode, the outer characteristic dimension R of the outer boundary 14 of the non-circular ring cavity 1 The radius is 100 microns, the deformation factor is 0.4, the emission wavelength of the device is 10 microns, and the inner feature size R of the inner boundary 15 of the non-circular ring cavity 2 It is 70 microns and the deformation factor is 0.4. The ring cavity is formed by reactive ion etching or wet etching. The inner and outer depths of the ring formed by the etching are the same, the active gain region 10 is exposed, the lower waveguide layer 11 is etched, and the substrate 12 is close. The lower electrode 13 of the non-circular ring ...

Embodiment 2

[0018] The inner boundary 15 of the non-circular ring cavity semiconductor laser is filled with insulating and heat-conducting material AlN; the others are the same as the first embodiment.

Embodiment 3

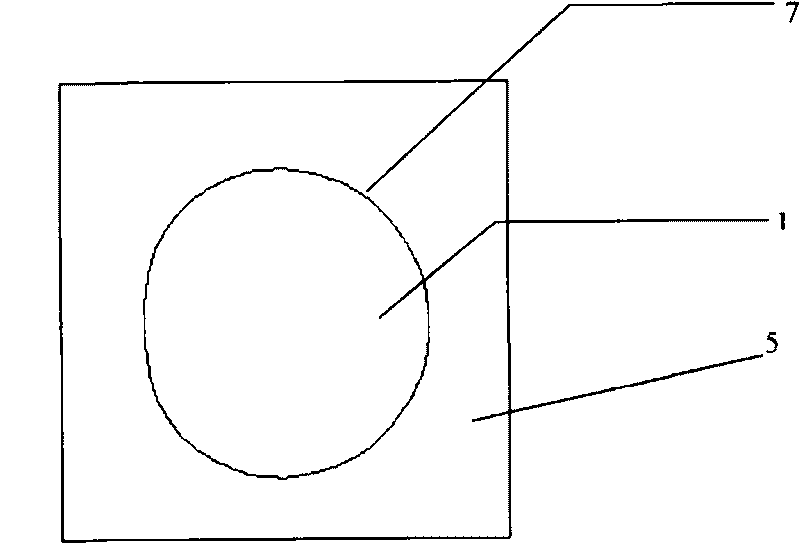

[0020] The upper electrode 8 of the non-circular ring cavity is a gold electrode, the upper waveguide layer 9 is InGaAsP, the active gain region 10 is an InGaAs / InAlAs quantum well cascade structure, the lower waveguide layer 11 is InGaAsP, the substrate 12 is InP and the lower electrode 13 is a gold electrode, the outer characteristic dimension R of the outer boundary of the non-circular ring cavity 14 1 The radius is 100 microns, the deformation factor is 0.4, the emission wavelength of the device is 10 microns, and the inner boundary 23 of the non-circular ring cavity is circular, such as Figure 5 As shown, the radius size is 70 microns, and the deformation factor is 0.4. The ring cavity is formed by reactive ion etching or wet etching. The inner and outer depths of the ring formed by the etching are the same, the active gain region 10 is exposed, the lower waveguide layer 11 is etched, and the substrate 12 is close. The lower electrode 13 of the non-circular ring cavity sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com