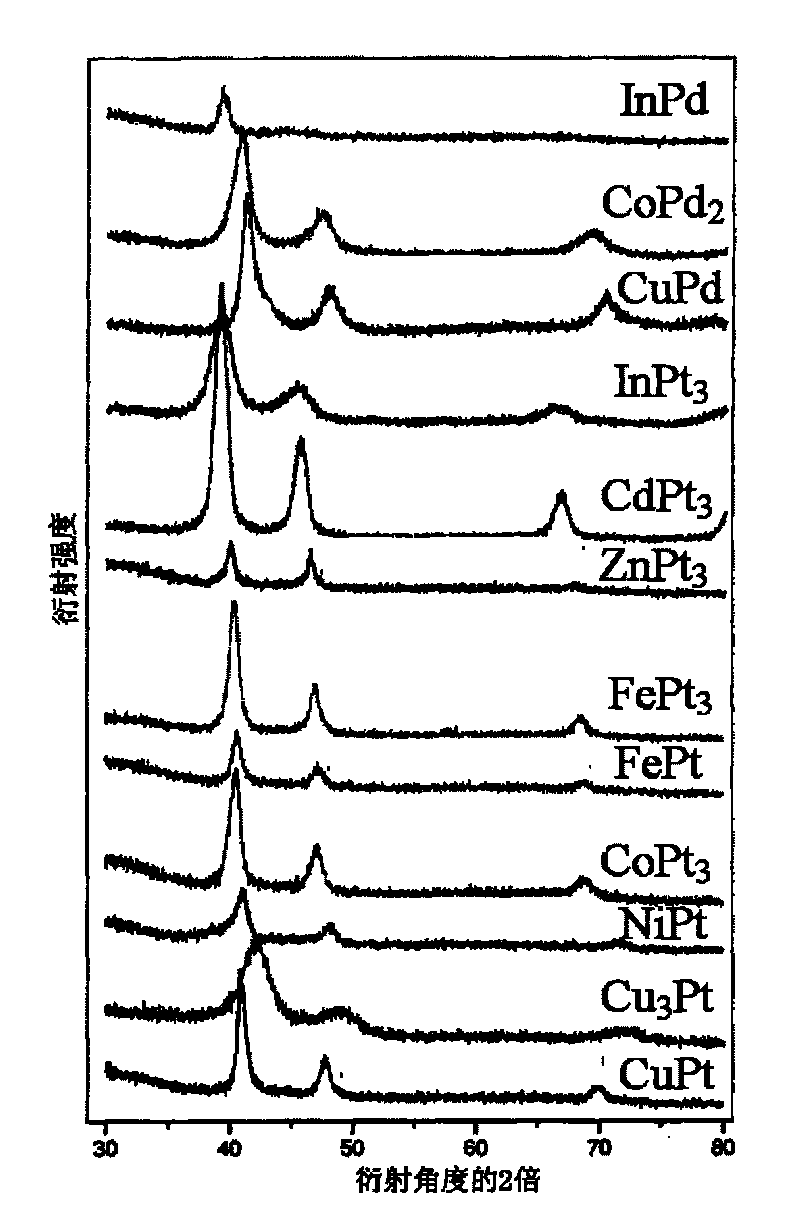

Method for synthesizing series alloy nanometer crystals

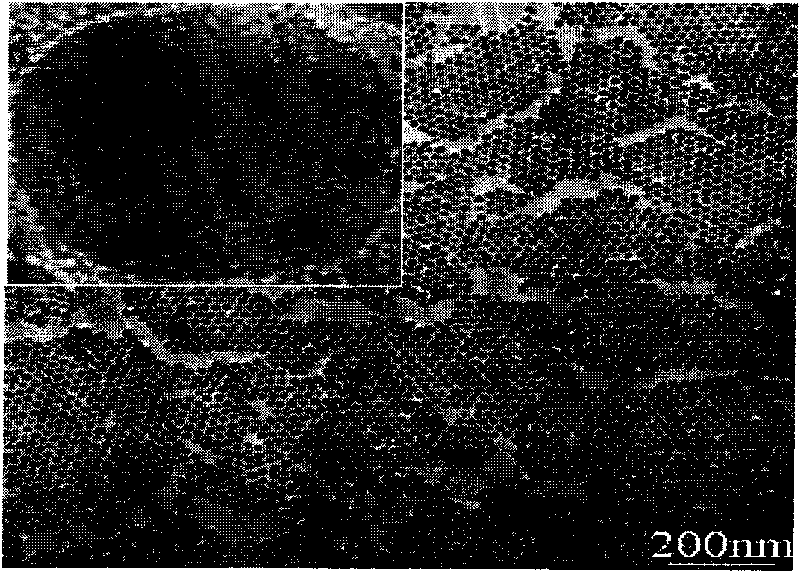

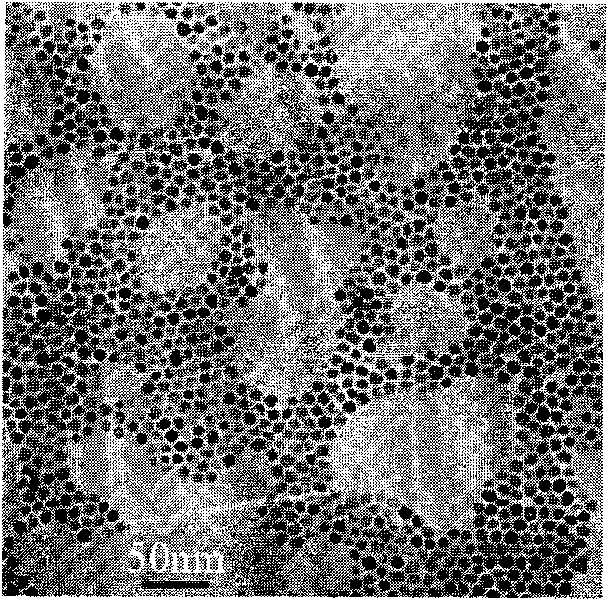

An alloy nanocrystal and a series of technologies, applied in nanotechnology, nanotechnology, nanostructure manufacturing and other directions, can solve the problems of unfavorable popularization and high cost of alloy nanocrystals, and achieve adjustable size, narrow particle size distribution, and uniform morphology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take 10ml of octadecylamine and heat it to 260°C, put into it the molar ratio of 1:1, copper nitrate and chloroplatinic acid with a total mass of 0.1g, react for 10 minutes, pour out the octadecylamine solvent and wash the precipitate with ethanol, Dry at 40°C to obtain CuPt alloy nanocrystals.

Embodiment 2

[0034] Take 10ml tetradecylamine and heat it to 180°C, put into it copper acetate and chloroplatinic acid with a molar ratio of 0.1:1 and a total mass of 0.01g, react for 60 minutes, pour out the oleylamine solvent and wash the precipitate with ethanol, 80 ℃ drying, CuPt alloy nanocrystals can be obtained.

Embodiment 3

[0036] Take 10ml of hexadecylamine and heat it to 200°C, put into it the molar ratio of 10:1, copper nitrate and chloroplatinic acid with a total mass of 1g, react for 60 minutes, pour out the hexadecylamine solvent and wash the precipitate with ethanol, 60 ℃ drying, CuPt alloy nanocrystals can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com