Method for treating zinc-containing electroplating wastewater and recovering zinc by electrolysis

A technology for electrolytic treatment and electroplating wastewater, applied in metallurgical wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of low removal rate, secondary pollution, complex process, etc., and reduce the side reaction of electrolysis hydrogen Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

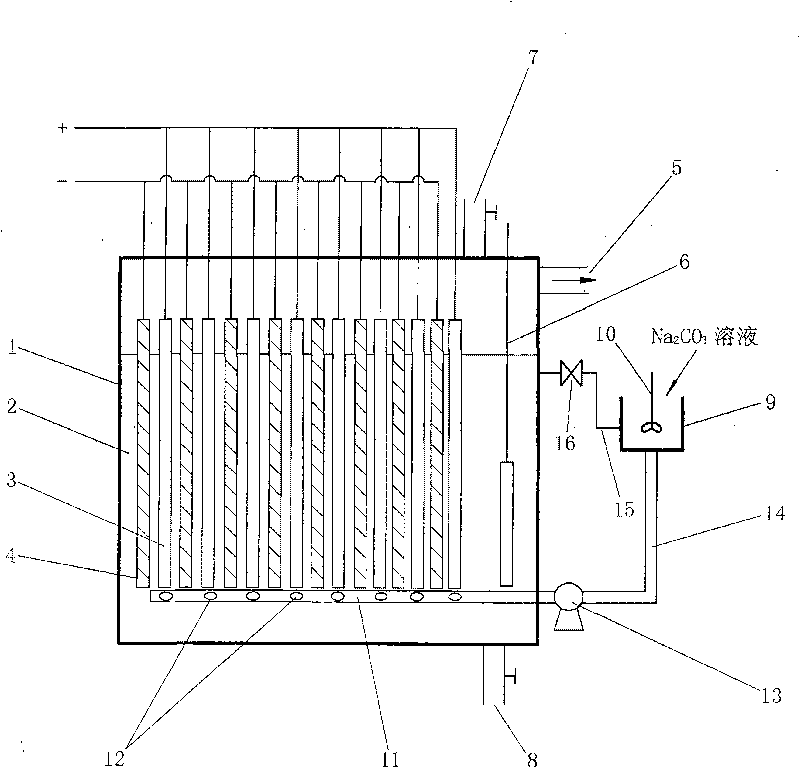

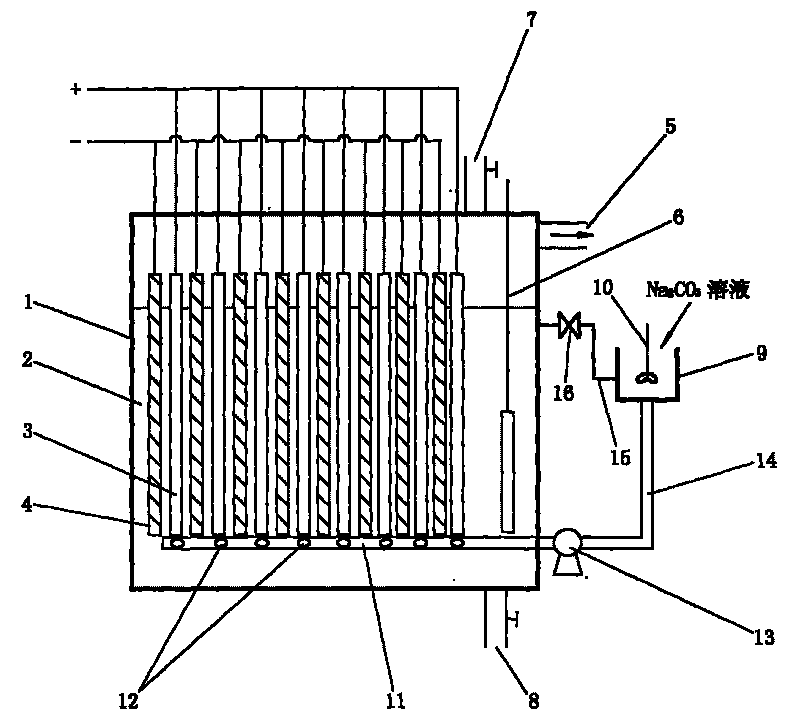

[0028] Refer to attached figure 1 , a method for electrolytically treating zinc-containing electroplating wastewater and recovering zinc. The electrolytic treatment of zinc-containing electroplating wastewater is carried out through an electrolytic treatment of zinc-containing electroplating wastewater. The electrolytic treatment of zinc-containing electroplating wastewater includes an electrolytic cell 1 and an electrolyte stirring device. The electrolytic cell 1 adopts a glass electrolytic cell, the anode 3 adopts a titanium-based platinum electrode, and the cathode 4 adopts a zinc electrode. The anode 3 and the cathode 4 are arranged alternately in a unipolar parallel manner, and the top of the electrolytic cell 1 is provided with an exhaust port 5 and a feed port 7. A valve is provided on the feed port 7, a pH meter 6 is provided in the electrolytic cell 1, a discharge port 8 is provided at the bottom of the electrolytic cell 1, and a valve is provided on the discharge port...

Embodiment 2

[0031] Refer to attached figure 1 , The electrolytic treatment of zinc-containing electroplating wastewater device for electrolytic purification of zinc-containing ion electroplating wastewater is the same as in Example 1. The method for electrolytic treatment of zinc-containing electroplating wastewater is: the electroplating wastewater with a zinc concentration of 150.0 mg / L enters the electrolytic cell 1 through the feed port 7 as the electrolyte 2, and an appropriate amount of Na is added to the electrolyte 2 2 C O 3 solution to adjust the pH value of the electroplating wastewater to 6.0, and the distance between the anode 3 and the cathode 4 is 20 mm. During electrolysis, through 15V DC, Na 2 CO 3 Add the solution into the pH adjustment tank 9 of the electrolyte stirring device, and slowly add 5 mol / L Na 2 CO 3 The solution makes the pH value of the electroplating wastewater reach 6.8, and the electrolysis time is 4 hours; in the electrolysis process, the interval ti...

Embodiment 3

[0033] Refer to attached figure 1 , The electrolytic treatment device for electrolytic treatment of zinc-containing electroplating wastewater is basically the same as that of Example 1, wherein the cathode 4 uses a graphite electrode. The method for electrolytic treatment of zinc-containing electroplating wastewater is: the electroplating wastewater with a zinc concentration of 150.0 mg / L enters the electrolytic cell 1 through the feed port 7 as the electrolyte 2, and an appropriate amount of Na is added to the electrolyte 2 2 CO 3 The solution adjusts the pH value of the electroplating wastewater to 6.1, and the distance between the anode 3 and the cathode 4 is 22mm; during electrolysis, 10V direct current is passed, and Na 2 CO 3 Add the solution into the pH adjustment tank 9 of the electrolyte stirring device, and slowly add 5 mol / L Na 2 CO 3 The solution makes the pH value of the electroplating wastewater reach 7.0, and the electrolysis time is 2 hours; in the electrol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com