Method for producing oxygen bridge material

A production method and oxygen bridge technology, applied in the direction of steroids, organic chemistry, etc., can solve the problems of easy explosion and low product quality, and achieve the effects of improving safety, increasing efficiency, saving costs and man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

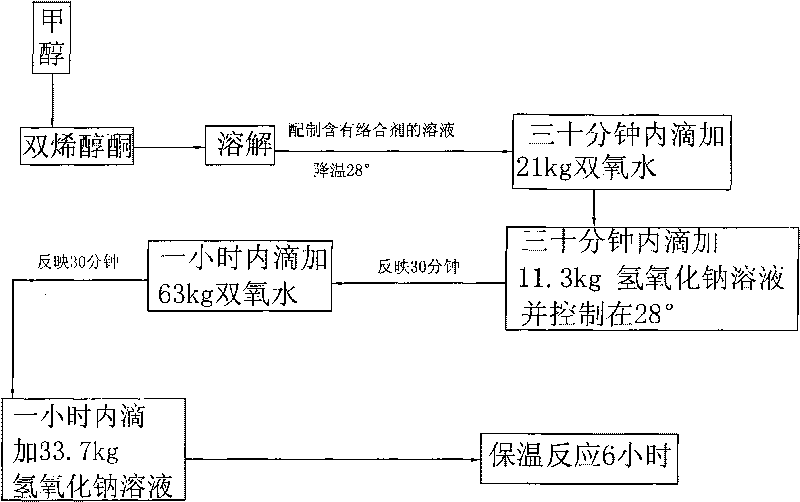

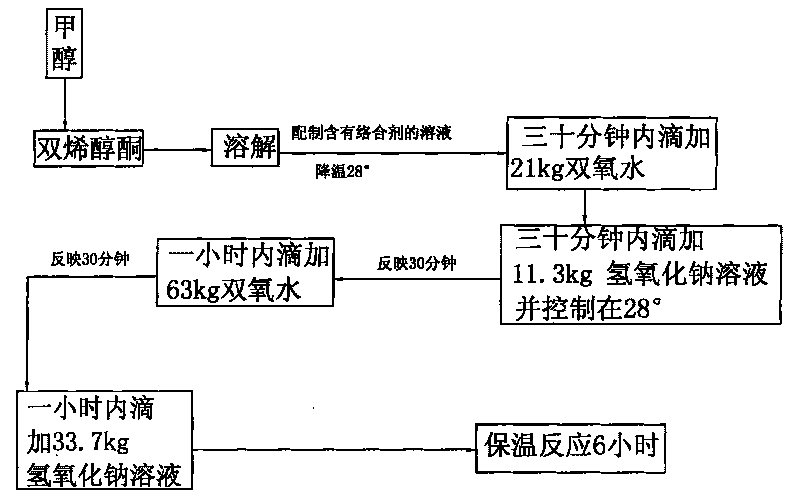

[0016] Such as figure 1 shown.

[0017] First, 1000L industrial methanol is pumped into the reaction tank, the content of methanol is ≥98%, and then 100kg of dienolketone with a content of ≥98.5% is put into the methanol solution, and the dienolketone is stirred and heated in the methanol solution to Dienolone is completely dissolved at 55±2°C, then the solution is cooled to 26°C±2°C, and an industrial sodium hydroxide aqueous solution is prepared during the cooling process, wherein the sodium hydroxide aqueous solution is 30kg of water and 15kg of solid sodium hydroxide Prepared, the content of sodium hydroxide is ≥ 95%, and 500g of industrial sodium silicate complexing agent with a content of ≥ 98% is added to the above alkaline water solution;

[0018] Next, add 21kg of hydrogen peroxide dropwise in the above solution in 30-35 minutes, after stirring for 10 minutes, then add 11.3kg of alkaline water dropwise in 30-35 minutes, the dropping rate is 0.38L / min, wherein alkalin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com