Preparation method of polysiloxane-polyphenylether segmented copolymer for penetrative vaporization film material

A pervaporation membrane, polysiloxane technology, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology and other directions, can solve the problems of complex reaction process and high reaction requirements, achieve simple reaction process, wide application fields, The effect of good separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

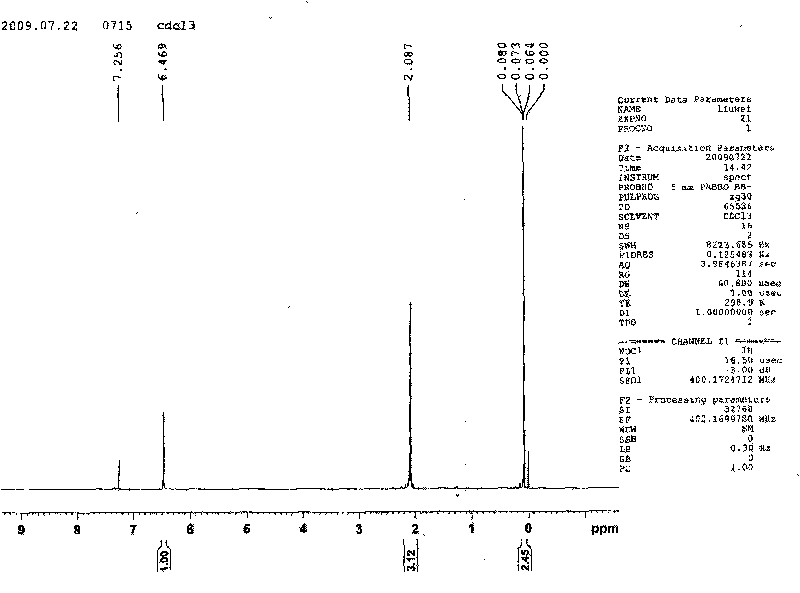

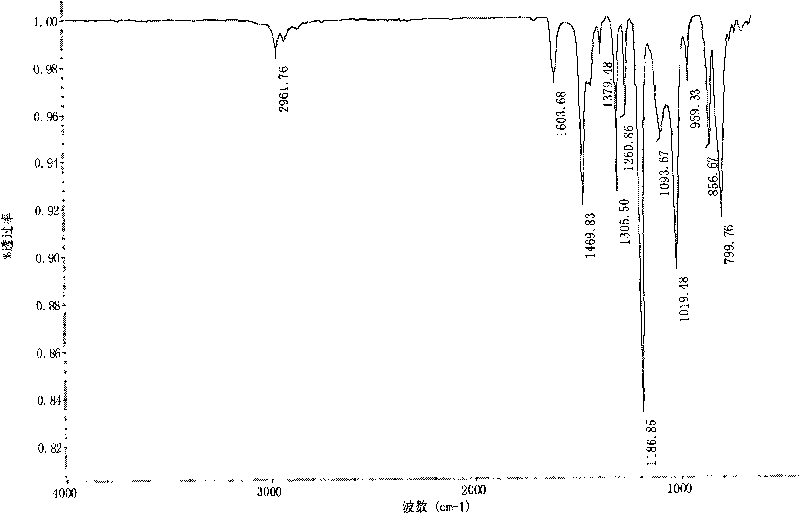

[0034] Get 15g carboxy-terminated poly-2,6-dimethylphenylene ether (molecular weight 12000g / mol) and dissolve it in chlorobenzene for subsequent use, get 81.8g hydroxyl-terminated polydimethylsiloxane (molecular weight 10040g / mol) and dissolve it in chlorine In benzene, add polydimethylsiloxane solution into a dry 500ml four-neck flask equipped with a thermometer, condenser and stirring, then add 0.5g of dilute nitric acid (1mol / L), and divide at 120°C Add poly-2,6-dimethylphenyl ether solution in 5 batches, add once every 90 minutes, and react for 8 hours in total; Wash and filter with suction to obtain 95.8 g of polydimethylsiloxane-poly-2,6-dimethylphenylene ether block copolymer.

[0035] The polyphenylene ether and polysiloxane structures are as follows

[0036]

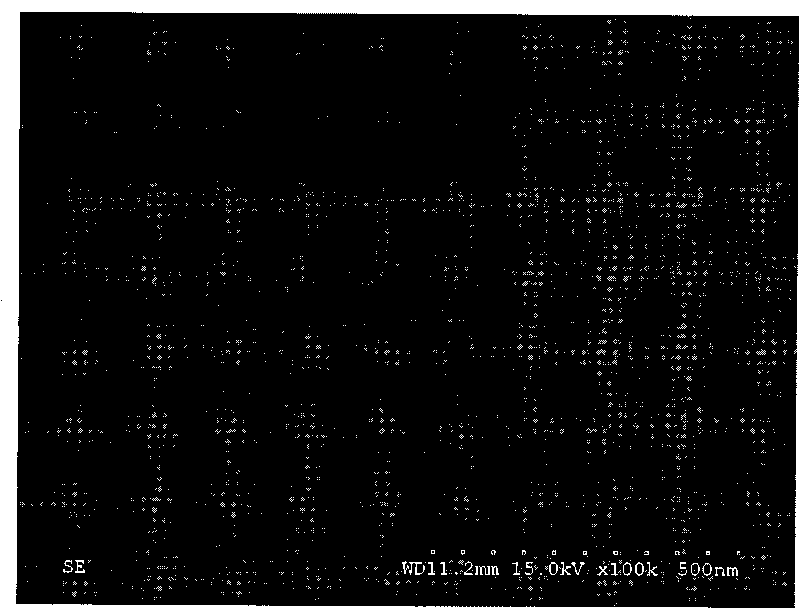

[0037]Dissolve polydimethylsiloxane-poly2,6-dimethylphenylene ether block copolymer in chloroform to prepare a casting solution, and evenly coat it on a glass plate, evaporate the solvent at room temperature...

Embodiment 2

[0042] Get 20g hydroxyl-terminated poly 2-methyl, 6-propylphenylene ether (molecular weight 16000g / mol) is dissolved in chlorobenzene for subsequent use, get 18.25g aminopropyl-terminated polymethylphenylsiloxane (molecular weight 11200g / mol) mol) was dissolved in chlorobenzene, and the polymethylphenylsiloxane solution was added to a dry 500ml four-necked flask equipped with a thermometer, a condenser tube and stirring, and then 0.24g of dilute nitric acid (1mol / L) was added, Add poly 2-methyl, 6-propylphenyl ether solution in 10 batches at 80°C, add once every 110min, and react for 24h in total; Precipitated, filtered, washed with water, washed with methanol, and suction filtered to obtain 34 g of polymethylphenylsiloxane-poly2-methyl, 6-propylphenylene ether block copolymer.

[0043] The polyphenylene ether and polysiloxane structures are as follows

[0044]

[0045] Dissolve polymethylphenylsiloxane-poly2-methyl, 6-propylphenylene ether block copolymer in trichlorethyl...

Embodiment 3

[0048] Get 20g aminopropyl-terminated poly-2,6-diphenylphenyl ether (molecular weight 16000g / mol) and dissolve it in chlorobenzene for subsequent use, get 30.75g carboxyl-terminated polydiphenylsiloxane (molecular weight 9200g / mol) to dissolve In toluene, add the polydiphenylsiloxane solution into a dry 500ml four-neck flask equipped with a thermometer, condenser and stirring, then add 0.1g trifluoroacetic acid (1mol / L), at 100°C Add poly-2,6-diphenylphenyl ether solution in 8 batches, add once every 100min, and react for 16h in total; after the reaction, filter to remove solid insoluble matter, precipitate the product from the reaction solution with methanol, filter, and wash with water , washed with methanol, and suction filtered to obtain 45.3 g of polydiphenylsiloxane-poly-2,6-diphenylphenylene ether block copolymer.

[0049] The polyphenylene ether and polysiloxane structures are as follows

[0050]

[0051] Dissolve polydiphenylsiloxane-polyphenylene ether block copo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Separation factor | aaaaa | aaaaa |

| Separation factor | aaaaa | aaaaa |

| Separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com