Mothproof fabric and preparation method thereof

A fabric and surface layer technology, applied in botany equipment and methods, biochemical fiber treatment, biocide, etc., can solve the problems of inability to manufacture diameters, etc., and achieve the effect of strong insect attack ability, short production process, and long-lasting anti-mosquito effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

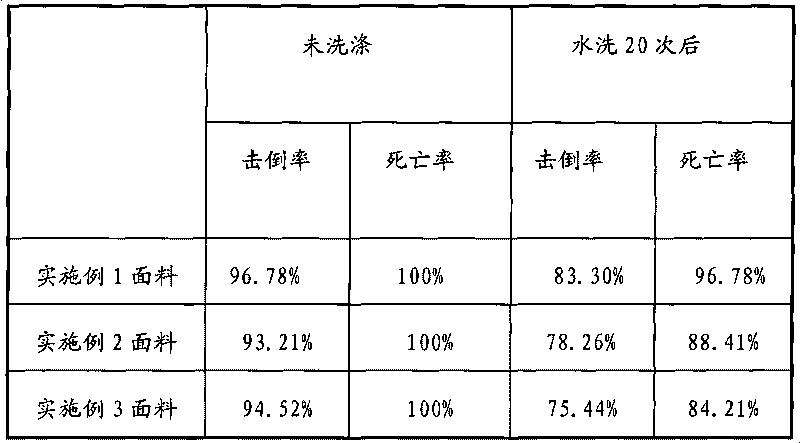

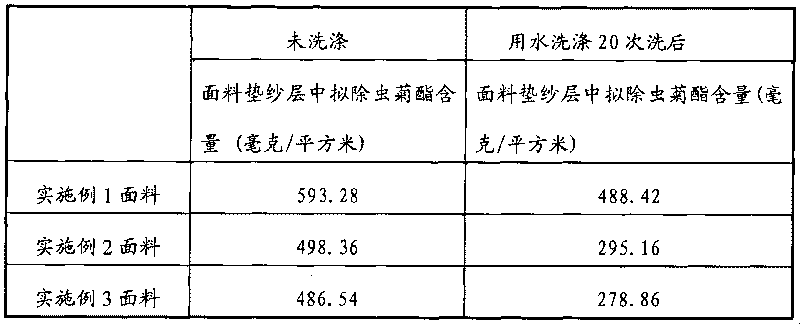

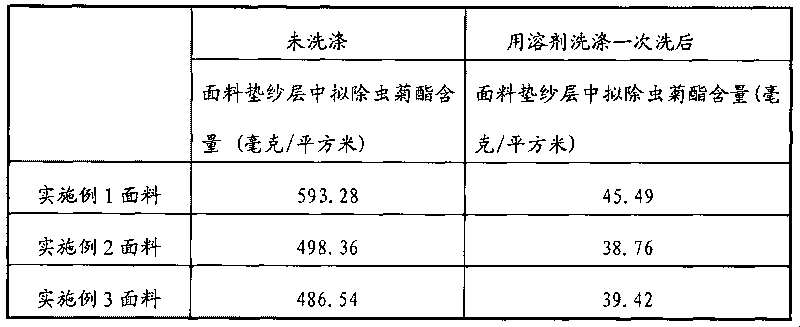

Examples

Embodiment 1

[0057] 1. Raw materials:

[0058] Inner layer material, inner yarn 1 and 2, use 60 / 2 combed army green cotton fiber;

[0059] Yarn layer material, yarn layer yarn 3, choose 33dTex / 1F polyethylene monofilament fiber, the diameter is about 0.09 mm;

[0060] Surface material, veil 5 and 6, choose 83dTex / 144F army green polyester low elastic fiber.

[0061] 2. Warping:

[0062] The warping machine is DS21 of Karl Mayer Company of Germany, and the pan head specification is 21 inches. Lining yarns 1 and 2, laying yarn layer 3, and veils 5 and 6 correspond to pan heads with the same number respectively. No. 1, 2, 5, and 6 pan heads have 230 fiber grains, No. 3 pan head fibers have 460 grains, and 1, 2, 3, 5, and 6 each use 4 pan heads. The machine speed is 400 rpm.

[0063] 3. Cream preparation:

[0064] Add 1 kg of deltamethrin into 10 kg of ethylene glycol butyl ether solvent, heat to 50°C, stir until the deltamethrin is completely dissolved, and then stir for 10 minutes to m...

Embodiment 2

[0075] 1. Raw materials:

[0076] Inner layer material, inner yarn 1 and 2, use 83dTex / 18F army green rayon fiber;

[0077] Yarn layer material, yarn layer yarn 3, choose 20D polypropylene fiber monofilament;

[0078] Surface material, veil 5 and 6, select 150D144F army green polyester (polyester) filament.

[0079] 2. Cream preparation:

[0080] Add 1 kg of cyhalothrin into 5 kg of ethylene glycol butyl ether solvent, heat to 50°C, stir until the cyhalothrin is completely dissolved, and then stir for 10 minutes to make an emulsifiable concentrate.

[0081] 3. Dip dyeing:

[0082] Dye the layered yarn 3, veil 5 and 6 respectively in the dyeing solution in the form of skeins or bobbins, the temperature of the dipping is raised to 60°C at a rate of 1.5°C / min, and the holding time of the dipping is 40min; The liquid mass ratio is 1:20, and the amount of emulsifiable concentrate is 10% of the yarn mass.

[0083] 4. Warping:

[0084] The warping machine is DS21 of Karl Mayer ...

Embodiment 3

[0091] 1. Raw materials:

[0092] Inner layer material, inner yarn 1 and 2, use 60 / 2 army green combed cotton fiber;

[0093] Yarn layer material, yarn layer yarn 3, choose 20D polypropylene fiber monofilament;

[0094] The surface layer material, veil 5 and 6, select army green acrylic fiber (polyacrylonitrile) 100D48F filament.

[0095] 2. Warping:

[0096] The warping machine is DS21 of Karl Mayer Company of Germany, and the pan head specification is 21 inches. Lining yarns 1 and 2, laying yarn layer 3, and veils 5 and 6 correspond to pan heads with the same number respectively. No. 1, 2, 5, and 6 pan heads have 230 fiber grains, No. 3 pan head fibers have 460 grains, and 1, 2, 3, 5, and 6 each use 4 pan heads. The machine speed is 400 rpm.

[0097] 3. Cream preparation:

[0098] Add 1 kg of deltamethrin into 20 kg of propylene glycol methyl ether solvent, heat to 55°C, stir until all deltamethrin is dissolved, and then stir for 10 minutes to make emulsifiable concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com