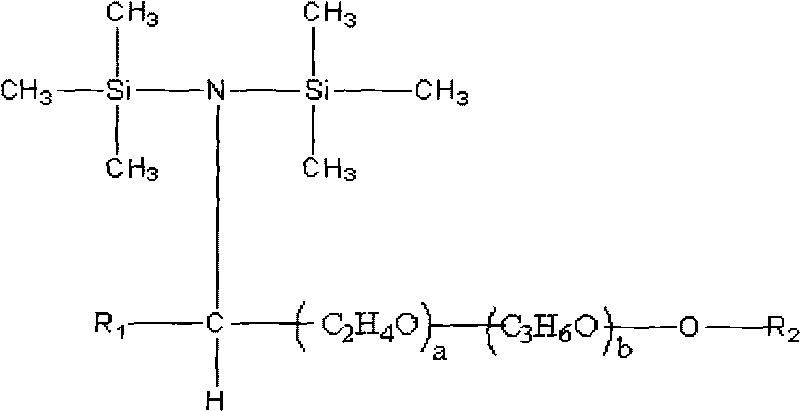

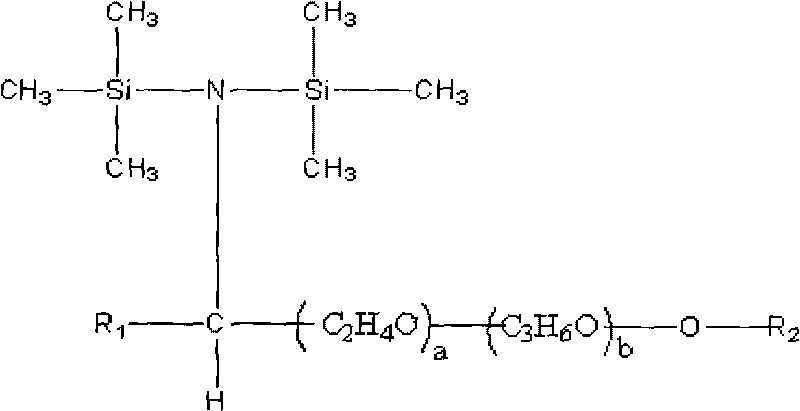

Organic silicon pesticide synergist and preparation method thereof

A technology of organosilicon and synergist, which is applied in the field of preparation of polyether-modified trisiloxane, can solve the problems of reduced yield and achieve the effects of less side reactions, high yield, and good physiological safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

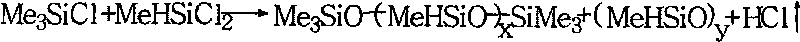

Method used

Image

Examples

Embodiment 1

[0061] a. Synthesis of special polyether:

[0062] 1.1

[0063] Put 81g of sodium methoxide and 162g of methanol into a 1L stainless steel reaction kettle to completely dissolve the sodium methoxide, then add 550g of ethylene oxide, stir at high speed, heat up to 100°C, and the pressure of the autoclave is 1 to 2.0 atm. With the progress of the reaction, the pressure gradually decreased. When the pressure in the kettle was 1.2 atm, the temperature was lowered to normal temperature to obtain the sodium salt of polyoxyethylene ether end-capped with methoxy groups:

[0064]

[0065] 1.2 Move the obtained polyoxyethylene ether sodium salt to the normal pressure reaction kettle, after steaming the methanol, add 160 g of ethylene dichloride in the kettle, stir at a high speed, be warming up to the reflux temperature, react for 2.5 hours, steam out The reacted dichloroethane was decolorized and filtered to obtain the chlorine-terminated polyether:

[0066]

[0067] C, the syn...

Embodiment 2

[0076] a1. Synthesis of special polyether:

[0077] 1.1 Add 27g of sodium methoxide into the autoclave, then add 60g of methanol and stir to fully dissolve it, add 210g of propylene oxide, stir at high speed, heat up to about 105°C, and the pressure in the kettle rises to 1.7atm. With the progress of the reaction, the pressure gradually decreased. When the pressure dropped to 1.1-1.2 atm, it was lowered to room temperature, then 201 g of ethylene oxide was added, and the temperature was raised to about 110 °C. The pressure in the kettle was 1.8-2.0 atm. When the pressure in the kettle drops to 1.1 to 1.2 atm, the temperature of the kettle is lowered to room temperature, and methanol is evaporated to obtain a methanol solution of methoxy-terminated epoxy polyether sodium salt:

[0078]

[0079] 1.2 The obtained methoxy-terminated epoxy polyether sodium salt (390g) was moved to the normal pressure reaction kettle, after steaming the methanol, 55g of ethylene dichloride was ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com