Method for industrially preparing sodium alginate micro-capsule loading high-density cells

A sodium alginate, high-density technology, applied in microcapsules, capsule delivery, pharmaceutical formulations, etc., can solve the problem of not being able to meet the needs of industrial production, wide particle size distribution of sodium alginate microcapsules, and failure to achieve high-density microencapsulation Cells and other problems, to achieve the effect of narrow particle size distribution range, uniform particle size distribution of microcapsules, and concentrated particle size distribution of microcapsules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of sodium alginate solution

[0024] Weigh 20 g of sodium alginate, dissolve it in 100 ml of sterilized physiological saline, and filter aseptically through a 0.22 μm microporous membrane to obtain a 2% sodium alginate solution.

[0025] (2) Cells are mixed with sodium alginate solution

[0026]Divide the total number of cells to 5 x 10 7 One bovine adrenal medulla chromaffin cells (BCC) and 10ml of 2% sodium alginate solution were prepared into a suspension by stirring.

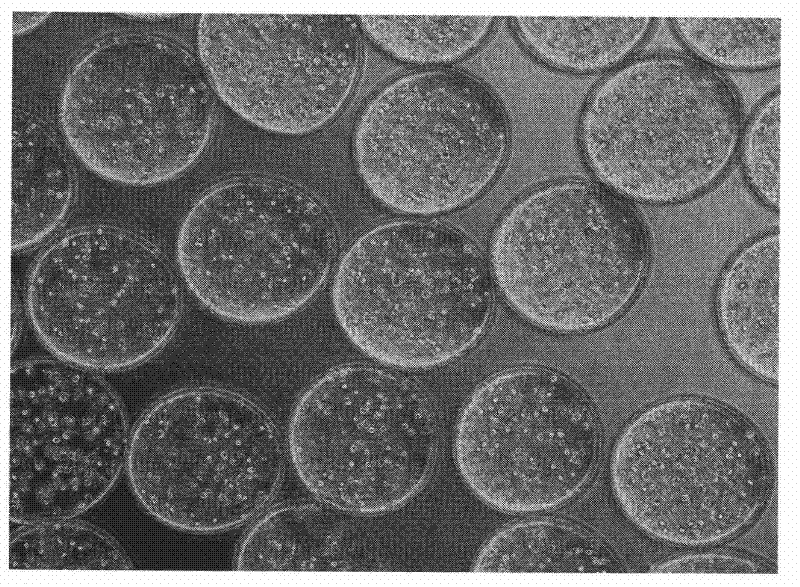

[0027] (3) Preparation of calcium alginate microspheres

[0028] Using the Inotech IE-50R Encapsulator microcapsule instrument, using the vibrating nozzle method (Vibrating jetbreakup), by adjusting the size of the nozzle, controlling the flow rate, vibration frequency and other process parameters, spray the suspension to 300ml with a concentration of 100mmol / L containing 0.5% polo Sham(F68)CaCl 2 In the solution, calcium alginate microspheres with a diameter in the range of 200-40...

Embodiment 2

[0037] (1) Preparation of sodium alginate solution

[0038] Weigh 22 g of sodium alginate, dissolve it in 100 ml of sterilized physiological saline, and filter aseptically through a 0.22 μm microporous membrane to obtain a 2.2% sodium alginate solution.

[0039] (2) Cells are mixed with sodium alginate solution

[0040] Divide the total number of cells to 10 x 10 7 One bovine adrenal medulla chromaffin cells (BCC) and 10 ml of 2.2% sodium alginate solution were prepared into a suspension by stirring.

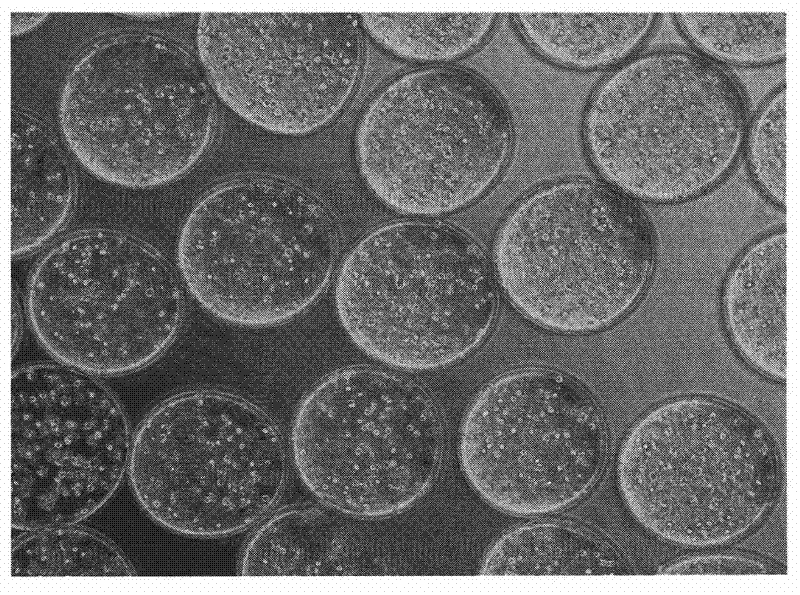

[0041] (3) Preparation of calcium alginate microspheres

[0042] Inotech IE-50R Encapsulator microcapsule instrument, using the vibrating jet breakup method (Vibrating jet breakup), by adjusting the size of the nozzle, controlling the flow rate, vibration frequency and other process parameters, spray the suspension to 300ml with a concentration of 100mmol / L containing 0.2% HSA (for injection) CaCl 2 In the solution, calcium alginate microspheres with a diameter in the range ...

Embodiment 3

[0050] Embodiment 3: each step is equal to embodiment 1 or 2, but different therefrom, the concentration of the sodium alginate solution obtained in the preparation of step (1) sodium alginate solution is 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com