High volume fraction grain enhanced aluminum-base compound material brazing filler metal and preparation method thereof

A particle-reinforced aluminum, high volume fraction technology, used in welding equipment, welding/cutting media/materials, welding media, etc., can solve problems such as poor corrosion resistance and poor brazing, and achieve improved bonding quality, strength and plasticity. , the effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

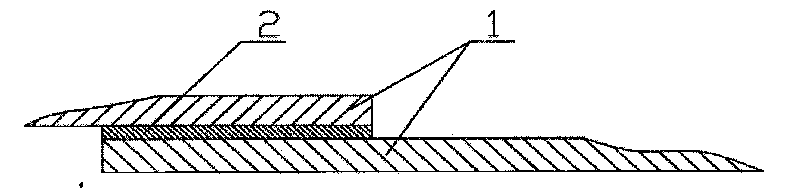

[0011] Specific embodiments: In this embodiment, the high volume fraction particle reinforced aluminum matrix composite material brazing self-brazing filler metal is characterized in that the high volume fraction particle reinforced aluminum matrix composite material brazing self-brazing filler metal is foil-shaped, and its composition is as follows The mass percentage is made of 15%-26% Cu, 4%-10% Si, 0.5%-2% Mg, 0.05%-0.1% Bi, 0.01%-0.03% La, 0.5%-1.0% Li and the balance of Al become.

[0012] The use of this brazing material to braze high volume percentage particle-reinforced aluminum matrix composite materials needs to be carried out in a vacuum state, and the surface of the composite material before welding must be as smooth and flat as possible, after grinding and polishing, the brazing temperature 550~570℃, the vacuum degree is 10×10 -3 Pa, apply a certain pressure.

[0013] The invention is suitable for the brazing of the silicon carbide particle reinforced aluminum ...

specific Embodiment approach 2

[0014] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the composition of high volume fraction particle reinforced aluminum matrix composite brazing self-brazing filler metal is from 18% to 22% Cu, 5% to 8% by mass percentage %Si, 1.0%~1.8%Mg, 0.06%~0.08%Bi, 0.015%~0.025%La, 0.6%~0.8%Li and the balance Al.

specific Embodiment approach 3

[0015] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the composition of high volume fraction particle reinforced aluminum matrix composite material brazing self-brazing filler metal is composed of 20% Cu, 6% Si, 1.5% Mg by mass percentage , 0.07% Bi, 0.02% La, 0.7% Li and 71.71% Al.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com