Process for pre-compacting prepreg overlay of resin-based composite material

A technology of composite materials and prepregs, applied in lamination, lamination devices, lamination auxiliary operations, etc., can solve problems such as large wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

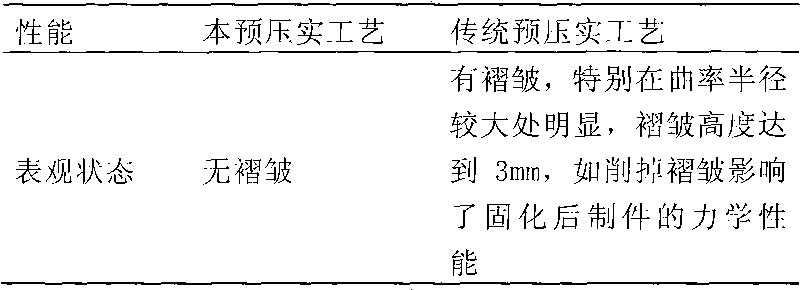

Embodiment 1

[0016] Choose the uniform pressure transmission layer as barbed wire mesh, the wire diameter is 0.5mm, and the hole is 2mm square, lay it on the surface of the hyperbolic male mold, then spread the PTFE cloth and air felt, use the vacuum bag and sealing tape to seal and pump Vacuum, stay at room temperature for 10 minutes and then open the vacuum bag. Lay the skin material according to the requirements of the drawings. The skin material is SW-280A / 3218. After laying 6 layers, then lay the non-porous film, iron wire uniform pressure transmission layer, PTFE cloth and air felt in turn, and use vacuum bag After sealing with the sealing tape, vacuumize, push into the autoclave, vacuumize at room temperature and raise the temperature to the mold temperature of 70°C±5°C, open the can and push out the mold after 30 minutes of heat preservation, keep the vacuum until the mold temperature is lower than 40°C, open Vacuum bag. The comparison of its pre-compacted quality with that of the...

Embodiment 2

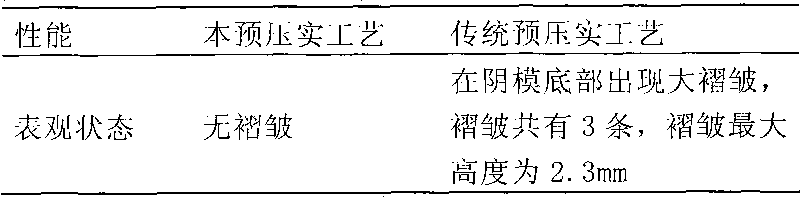

[0020] The uniform pressure-transmitting layer is selected as Nomex paper honeycomb, the grade is NH-1-1.83-48, which is a hexagon with a cell side length of 2.75mm, a density of 48kg / m3, and a honeycomb thickness of 2mm to 3mm. Lay the skin material according to the requirements of the drawings. The mold is a hyperboloid female mold, and the skin material is T700 / 3234. After laying 16 layers according to the angle, then lay the non-porous film, the honeycomb uniform pressure transmission layer, and the PTFE cloth in sequence. and air felt, use vacuum bags and sealing strips to seal and vacuumize, push into the autoclave, vacuumize at room temperature and heat up to the mold temperature of 70°C±5°C, open the can and push out the mold after 30 minutes of heat preservation, keep the vacuum, wait for the mold If the temperature is lower than 40°C, open the vacuum bag. The comparison of its pre-compacted quality with that of the traditional pre-compacted surface without a uniform ...

Embodiment 3

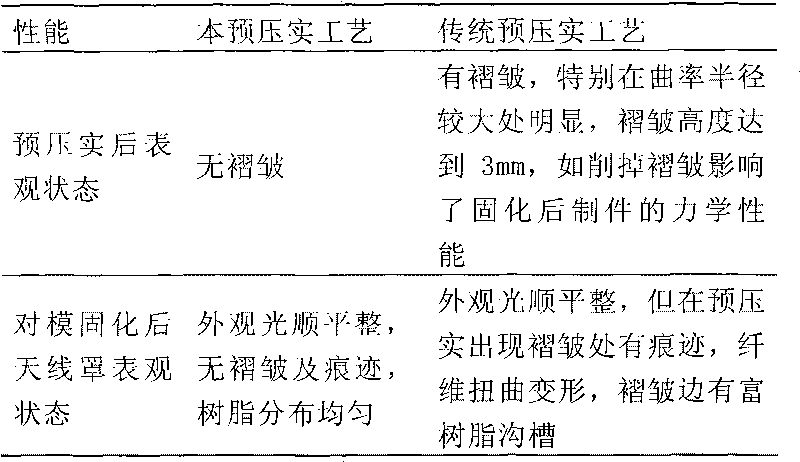

[0024] The uniform pressure transmission layer is selected as a copper wire mesh, the diameter of the copper wire is 0.3mm, and the hole grid is 2.5mm square. Cut the uniform pressure transmission layer according to the unfolded shape of the wing leading edge radome mold. According to the requirements of the drawings, lay up the radome material. The material is QW280 / 5528. After laying 12 layers, then lay the non-porous film, copper wire uniform pressure transmission layer, PTFE cloth and air felt in turn, and use vacuum bag and seal After sealing the rubber strip, vacuumize it, push it into the oven, heat it up to the mold temperature of 100°C±5°C by vacuuming at room temperature, and keep it warm for 10 minutes, then push out the mold and keep the vacuum. When the mold temperature is lower than 60°C, open the vacuum bag. The comparison of its pre-compacted quality with that of the traditional pre-compacted surface without a uniform pressure-transmitting layer is shown in Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com