Magnetic flourescent nano material for magnetic-photo sensor and preparation method thereof

A fluorescent nanomaterial and nanomaterial technology are applied in the field of magnetic fluorescent nanomaterials and their preparation, which can solve the problems of reduced quantum yield and magnetic fluorescent nanoparticle quantum yield, and achieve the effect of improving the accuracy and sensitivity of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Prepare 20ml of FeCl with a molar concentration of 0.1mol / L 2 and 40ml of FeCl with a molar concentration of 0.1mol / L 3 Ethanol solution; take another 2.0 g of fluid-like carbon nanotubes with carboxylic acid functional groups, add them to 40 ml of absolute ethanol and stir for 30 min, place the two solutions in a shaker at 30-50 ° C for 24 h, and add mole The concentration is 17 ml of 1M ammonia water to obtain a composite solution in which magnetic nanoparticles grow on fluid-like carbon nanotubes; add gelatin or aspartic acid aqueous solution with a molar concentration of 0.1 mol / L to it according to a volume ratio of 2.5:1, and react for 4 hours , mixed and adsorbed repeatedly to obtain the fluid-like carbon nanotubes / MNPs nanomaterials coated with amphiphiles, which were dispersed in 40ml deionized water, and CdS@CdSe core-shell quantum dots dispersed in n-hexane at a molar ratio of 1:1 Ligand exchange is carried out to prepare fluid-like carbon nanotubes / MNPs / QDs...

Embodiment 2

[0024] Prepare 10ml of FeCl with a molar concentration of 0.1mol / L 2 and 20ml of FeCl with a molar concentration of 0.1mol / L 3 Absolute ethanol solution; take 3g of acidified carbon nanotubes and add them to 40ml of absolute ethanol and stir for 1h, mix the two and place them in a shaker at 30-50°C for 24h, add 20ml of NaOH solution with a molar concentration of 0.1M after dialysis, Continue to react for 5 hours to obtain an ethanol solution of acidified carbon nanotubes / MNPs nanoparticles, add 40ml of dendritic polyurethane aqueous solution with a molar concentration of 0.1mol / L to it according to the volume ratio of 2.5:1, and continue to react for 4h to obtain coated amphiphile molecules The acidified carbon nanotubes / MNPs nanoparticles were dispersed in 40ml deionized water, and the molar concentration of Au nanoparticles dispersed in dichloromethane was 0.1mol / L for ligand exchange to prepare acidified carbon nanotubes / MNPs MNPs / Au nanoparticle materials. Its quantum fl...

Embodiment 3

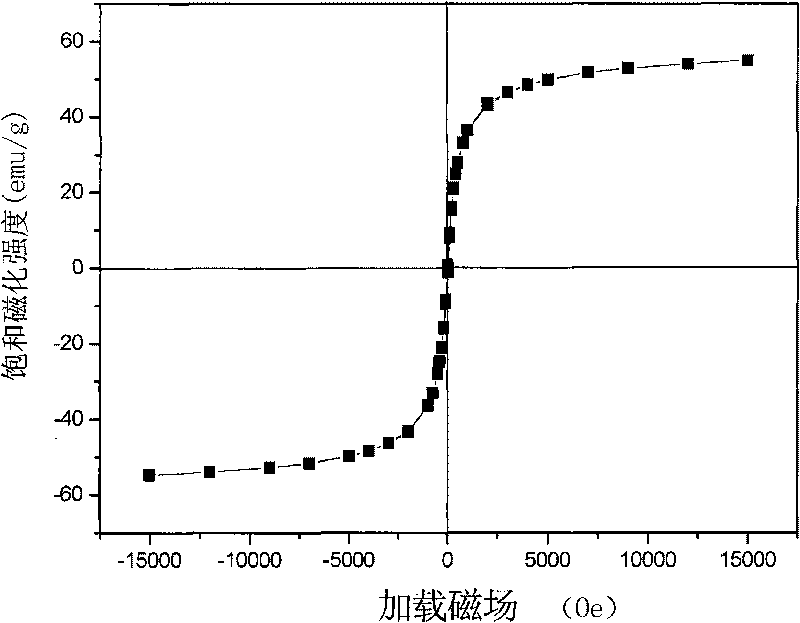

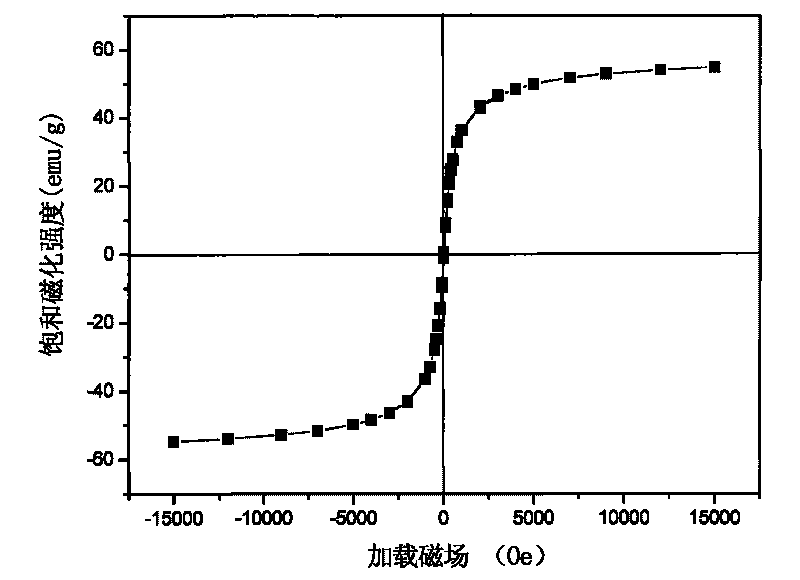

[0026] Dissolve 1.2g of polyaniline in 40ml of N-methylpyrrolidone, add 30ml of α-Fe with a molar concentration of 0.1mol / L 2 o 3 Stir in the N-methylpyrrolidone dispersion for 1 hour, place in a shaker at 30-50°C for uniform adsorption reaction for 24 hours, and then centrifuge for 3 times, each time for 15 minutes, at a speed of 5000 rpm. According to the volume ratio of 2:1, 35 ml of arginine aqueous solution with a molar concentration of 0.1 mol / L was added thereto, and after continuing to react for 4 hours, polyaniline / MNPs nanoparticles coated with amphiphilic molecules were obtained, which were dispersed in 35 ml of deionized water , Polyaniline / MNPs / QDs materials were prepared by ligand exchange with ZnS@CdSe quantum dots dispersed in n-hexane with a molar concentration of 0.15mol / L. Its quantum fluorescence yield is between 70%-80%, and its magnetic properties are 50-65emu / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com