Zinc oxide crystals and preparation method thereof

A technology of zinc oxide and crystal, which is applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems that it is not easy to obtain large +c slices, and the area of +c slices is small, and achieve low cost, good crystal quality, and fast growth speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be described below by taking the hydrothermal method as an example.

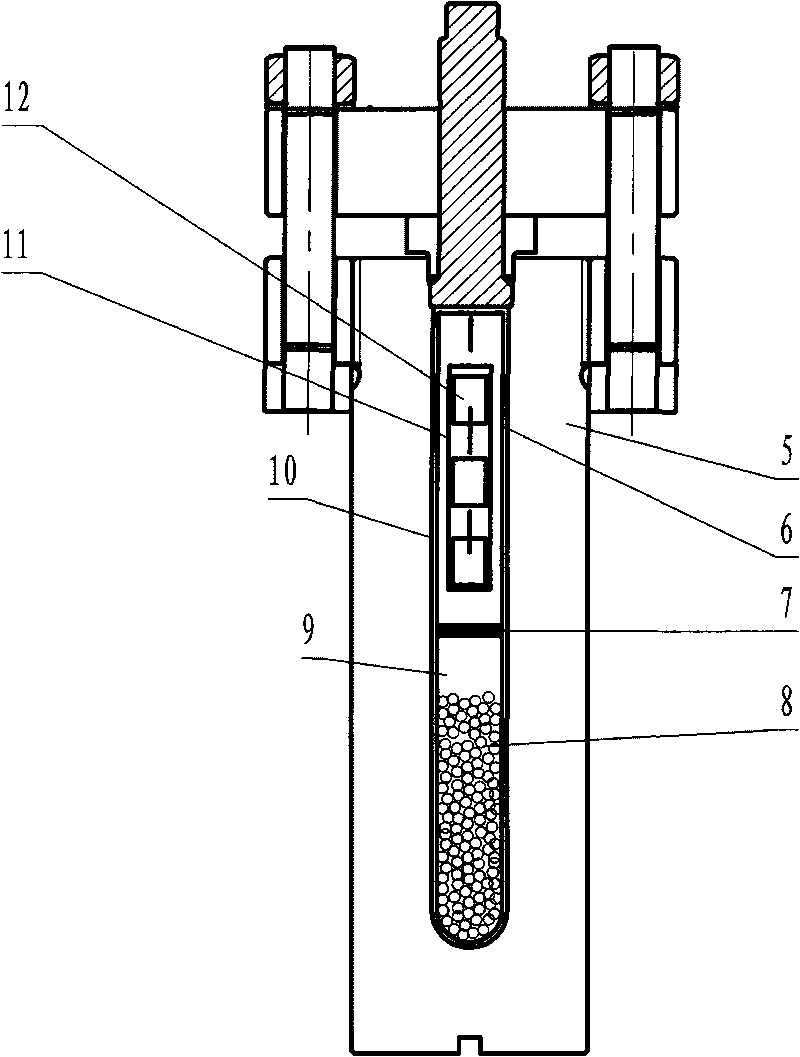

[0023] This embodiment uses image 3 The growth device shown is composed of an autoclave and a matching temperature difference well-type resistance furnace. The autoclave body 5 is provided with a gold bushing tube 6. In this embodiment, the inner cavity size of the gold bushing tube 6 is Φ38mm×750mm, tube wall thickness 0.8mm.

[0024] Sc: ZnO crystal is synthesized by hydrothermal method, the inner cavity of gold bushing tube 6 has a mixed solution of mineralizer and H2O, and the raw material of ceramic body made of unsintered ZnO powder and containing Sc 2 o 3 The compost 8 of composition is positioned at the bottom (that is, in the dissolving zone) of the gold liner tube 6 lumens, and the baffle plate 7 with holes is arranged on the compost 8 top, and the baffle plate 7 separates the gold liner tube 6 into the dissolution zone 9 and Growth z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com