Method for preparing biodegradable polyester catalyst

A technology of biodegrading polyester and catalyst, applied in the field of polymer materials, can solve the problems of yellowish color and poor transparency of the product, and achieve the effect of good hue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

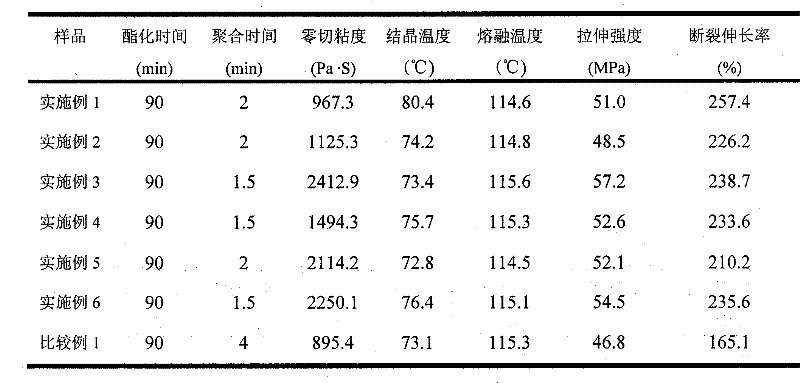

Examples

Embodiment 1

[0030] Preparation of Catalyst A

[0031] Add 18.9 g (0.1 mol) of titanium tetrachloride into a reactor equipped with a stirrer, then dilute with a certain amount of distilled water until no white smoke is generated, and mix well. Add cobaltous chloride 0.39g (0.003mol) in this solution again, stir and dissolve for 2 hours, adjust its pH with ammonia water to be 11, then precipitate and age for 8 hours, filter, and wash with distilled water until the solution does not contain chloride ions (with 0.1mol / L silver nitrate solution), dried, and calcined at 600°C for 4 hours to obtain a titania-cobalt oxide carrier. In a reactor equipped with a stirrer, a condenser and a thermometer, add 34g (0.1mol) of n-butyl titanate, 1.32g (0.005mol) of ethylpropyl orthosilicate, and 0.326g (0.001mol) of triphenyl phosphate The reaction was carried out at 150° C. for 3 hours. Titanium compound B was obtained. Then, 7.8 g of titanium compound B was added to the titanium dioxide-cobalt oxide c...

Embodiment 2

[0036] Preparation of Catalyst B

[0037] Add 18.9 g (0.1 mol) of titanium tetrachloride into a reactor equipped with a stirrer, then dilute with a certain amount of distilled water until no white smoke is generated, and mix well. Add aluminum trichloride 0.4g (0.003mol) in this solution again, stir and dissolve 2 hours, adjust its pH with ammoniacal liquor to be 11, then precipitate and age for 8 hours, filter, and wash with distilled water until the solution does not contain chloride ions ( Use 0.1mol / L silver nitrate solution to detect), dry, and bake at 600°C for 4 hours to obtain a titanium dioxide-alumina carrier. In the reactor equipped with stirrer, condenser and thermometer, add 28.4g (0.1mol) of tetraisopropyl titanate, 1.60g (0.005mol) of n-butyl silicate, 0.326g (0.001mol) of triphenyl phosphate ) was reacted at 150° C. for 3 hours. Titanium compound B was obtained. Then, 7.8 g of titanium compound B was added to the titanium dioxide-alumina carrier, refluxed fo...

Embodiment 3

[0042] Preparation of Catalyst C

[0043] Add 18.9 g (0.1 mol) of titanium tetrachloride into a reactor equipped with a stirrer, then dilute with a certain amount of distilled water until no white smoke is generated, and mix well. Add nickel chloride 0.71g (0.003mol) in this solution again, stir and dissolve for 2 hours, adjust its pH with ammoniacal liquor to be 11, then precipitate and age for 8 hours, filter, and wash with distilled water until the solution does not contain chloride ions (with 0.1mol / L silver nitrate solution), dried, and calcined at 600° C. for 4 hours to obtain a titania-nickel oxide carrier. In a reactor equipped with a stirrer, a condenser and a thermometer, add 22.8g (0.1mol) of tetraethyl titanate, 0.76g (0.005mol) of tetramethyl silicate, and 0.326g (0.001mol) of triphenyl phosphate The reaction was carried out at 150° C. for 3 hours. Titanium compound B was obtained. Then, 7.8 g of titanium compound B was added to the titanium dioxide-nickel oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com