Polyethylene material and polyethylene pipe

A technology of polyethylene and high-density polyethylene, applied in the field of polymer materials, can solve problems such as unstable pipe quality, affecting pipe quality, and difficulty in uniform dispersion, so as to improve anti-sag performance, improve overall performance, and increase the degree of dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

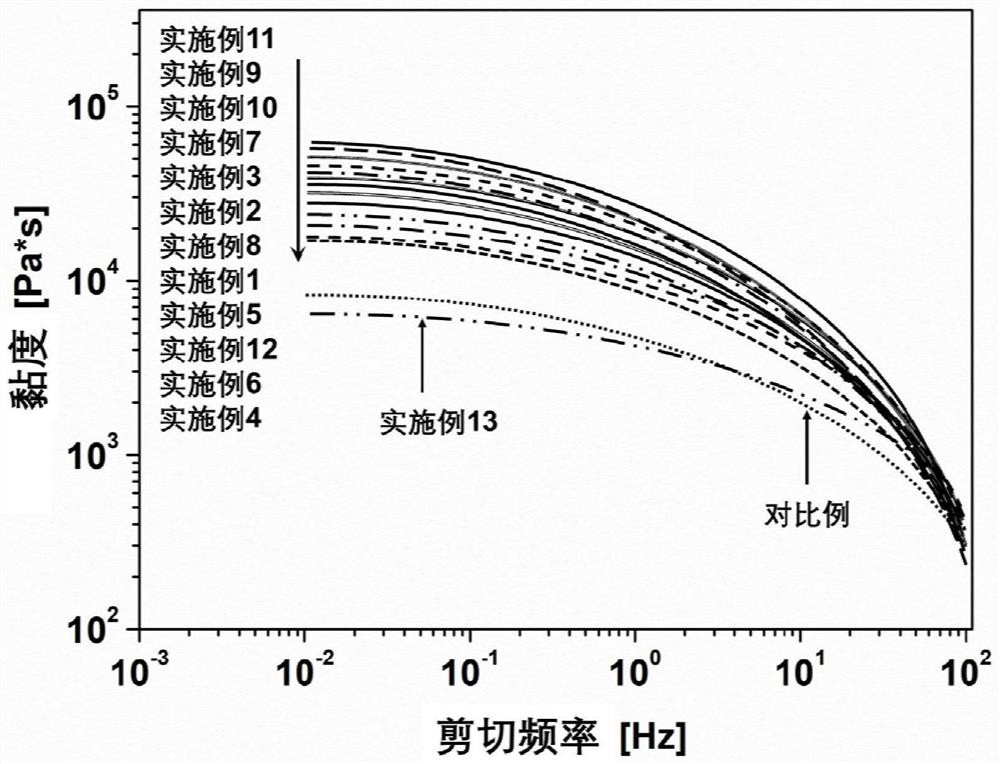

Image

Examples

Embodiment 1

[0061] Embodiment 1 prepares polyethylene material by following method:

[0062] Add POSS, malonic acid, glycerol, and 4-dimethylaminopyridine into the reaction vessel at a molar ratio of 0.1:1:1:0.001, protect with nitrogen, heat up, melt and stir for 4 hours, the reaction temperature is 120°C, and stir Speed 1000rpm. Add MDI by 1% of glycerol molar number, continue to react for 2h, obtain hyperbranched polyester. After drying the microcrystalline cellulose at 80° C. for 4 hours, it is directly added to the above-mentioned reaction vessel and subjected to vacuuming for 2 hours to obtain the cellulose modified by hyperbranched polyester.

[0063] Simultaneously, the reaction temperature and stirring speed remained unchanged. Weigh polyethylene resin, carbon black masterbatch, KH560 and cellulose modified by hyperbranched polyester according to the mass ratio of 100:5:0.1:1, mix them evenly, and then process granulation through twin-screw extrusion. The twin-screw extrusio...

Embodiment 2

[0066] The experimental process is basically the same as in Example 1, the difference is that: KH560 is adjusted to 2% of the polyethylene resin mass, the carbon black content in the carbon black masterbatch is adjusted to 45%, and the high-density polyethylene is adjusted to be 190 ° C and a pressure of 5 kg The melt index under the condition is 0.3g / 10min.

[0067] The carbon black dispersion grade of the final compound was 2.5.

Embodiment 3

[0069] The experimental process is basically the same as in Example 1, the difference is that the addition of hyperbranched polyester modified cellulose is 5% of the polyethylene resin quality, the carbon black content in the carbon black masterbatch is adjusted to 30%, and the high-density polyethylene The melt index is 0.03g / 10min at 190°C and a pressure of 5kg.

[0070] The carbon black dispersion grade of the final compound was 2.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com