Non-cyanide gilding saline solution

A technology of cyanide-free gold plating and salt solution, which is applied in the field of preparation of cyanide-free gold-plating salt solution, and can solve problems such as potential safety hazards, environmental pollution, and stability restrictions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

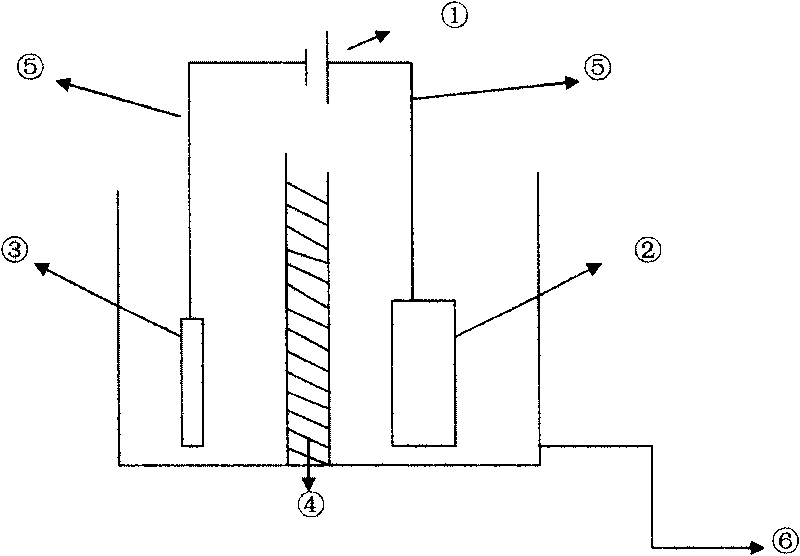

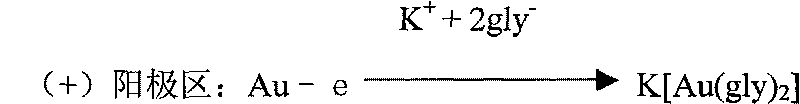

[0014] Prepare 900 milliliters of a mixture of 200 grams of aminoacetic acid and several grams of deionized water, adjust its pH to 9.5-10.2 with 35% sodium hydroxide solution, and finally fill it with deionized water to 1 liter, and place the solution in The cathode area and anode area of the IEMEC device as shown in the attached figure, wherein ① is a DC power supply, ② is a gold anode, ③ is a cathode plate, ④ is a cation exchange membrane, ⑤ is a wire, ⑥ is an IEMEC tank, and the cathode plate is made of 30 square centimeter stainless steel plate, the anode is 20 square centimeter gold, adjust the output voltage of the DC power supply at 12V±0.5V, keep the temperature of the solution in the cathode and anode areas in the range of 40-55°C, and test the solution in the anode area after 6 hours. The gold concentration is greater than 0.5 g / L, which means that the gold solution without cyanide can be prepared by this method.

Embodiment 2

[0016] Prepare 900 milliliters of a mixture consisting of 75 grams of aminoacetic acid, 75 grams of sulfoalanine, 50 grams of glutamic acid, 50 grams of potassium hydroxide and several grams of deionized water, and adjust its pH to 9.1-10.3, finally fill up to 1 liter with deionized water, and place the liquid in the cathode area and anode area of the IEMEC device as shown in the attached figure, where ① is a DC power supply, ② is a gold anode, and ③ is a cathode plate , ④ is a cation exchange membrane, ⑤ is a wire, ⑥ is an IEMEC tank body, the cathode plate is made of 25 square centimeter stainless steel plate, the anode is 25 micron thick and 25 square centimeter gold foil, and the output voltage of the adjustable DC power supply is in the range of 9V-11.5 , keep the temperature of the solution in the anode and cathode regions below 50°C, and after 8 hours, the anode region solution is detected to find that its gold concentration reaches 0.6 grams per liter, indicating that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com