Device and method for preparing oriented polysulfonamide superfine fiber by using magnetized electrostatic spinning method

An electrospinning method and technology of polysulfoneamide, which is applied in the field of devices for preparing orientation-arranged polysulfoneamide ultrafine fibers, achieves the effects of high repeatability, easy promotion, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

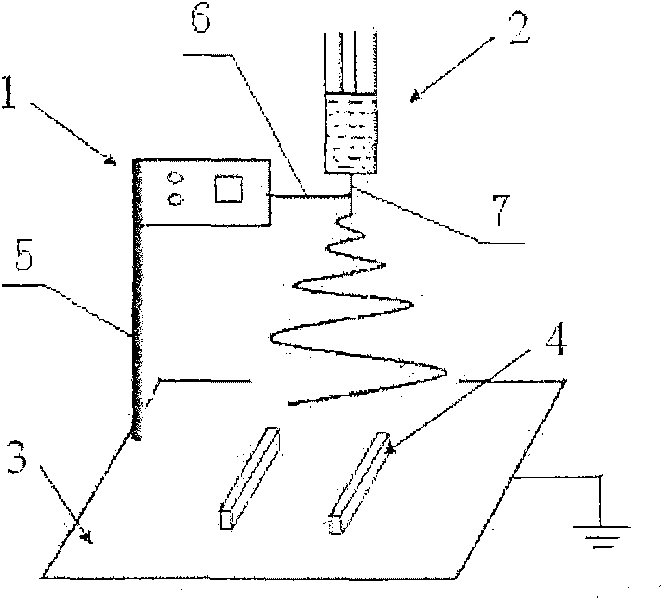

[0027] Embodiment 1, the concrete steps are as follows:

[0028] 1. Using 4,4'-diaminodiphenylsulfone and terephthaloyl chloride as monomers, and using dimethylacetamide DMAc as solvent, directly polycondensed to obtain PSA-DMAc solution, and obtained PSA-DMAc by calculating the quality of raw materials The mass percentage concentration of the solution is 32%, and then the solvent DMAc is added to dilute to obtain a pure PSA spinning solution with a mass percentage concentration of 16% for use.

[0029] 2. Preparation of oil-phase magnetic Fe 3 O 4 For solution, see Li LIU, Qinghua JIAO, Cheng PENG, Shijiang HE, Lihua WANG. Ultrasonic-assisted synthesis and strepavidin conjugation of amino-magnetic nanoparticles, Nuclear Science and Techniques, 19(6):370-375.

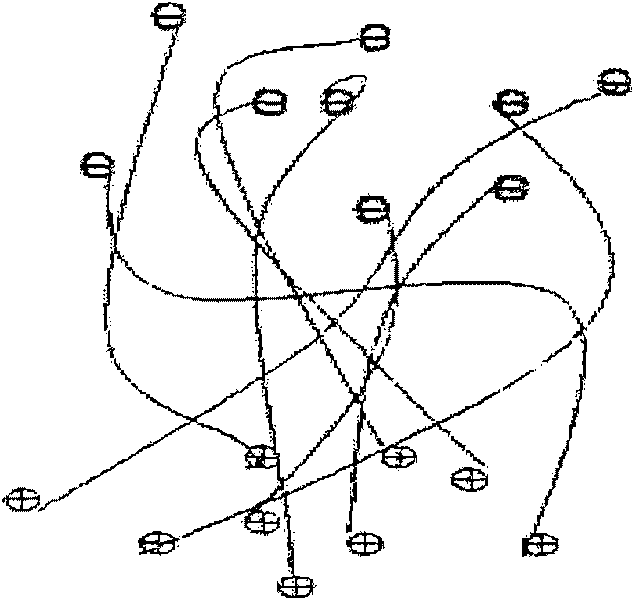

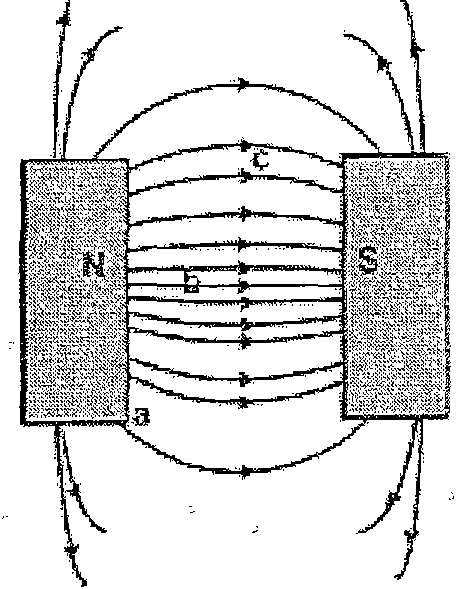

[0030] 3. At room temperature, place the homemade Fe 3 O 4 The solution was added dropwise to the pure PSA spinning solution, and ultrasonically dispersed for 12 h to obtain a magnetized PSA spinning solution for us...

Embodiment 2

[0032] Example 2: This example is basically the same as Example 1, the difference is: no oil-phase magnetic Fe is added to the PSA spinning solution 3 O 4 solution; a pair of parallel permanent magnets 4 are not placed on the aluminum foil receiver 3. The morphology of the spun fibers is shown in the attached Figure 5 .

Embodiment 3

[0033] Embodiment 3: This embodiment is basically the same as Embodiment 1, the difference is that a pair of parallel permanent magnets 4 are not placed on the aluminum foil receiver 3 . The morphology of the spun fibers is shown in Image 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com