Method for controlling X-ray exposing clearance

A technology of exposure gap and control method, which is applied in the field of exposure technology, can solve the problems that the parallelism between the mask and photoresist is difficult to ensure, and the X-ray gap is difficult to control, so as to reduce the exposure problem, solve the parallelism, and protect the mask. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0024] Control of example 1.1 μm gap (polymer material, etching process)

[0025] (1) Fabrication of 1 μm steps

[0026] Take a piece of silicon nitride mask (7.5mm×7.5mm silicon nitride wafer, 3mm×3mm film window), place it on the glue spinner, drop the polymer solution PMMA 950, spin coating at 500 rpm Coating for 10 seconds, spin coating for 30 seconds at 2000 rpm, then place the silicon nitride mask coated with PMMA on a hot stage at 180 degrees, bake for 90 seconds, and dry the solvent in PMMA to obtain the thickness PMMA of about 1 μm; expose the 3mm×3mm window of the silicon nitride mask, and protect other places, etch with a reactive ion etching machine, with an etching power of 35 watts and an oxygen flow rate of 30 liters / min. 3min, PMMA is removed, and a polymer step with a thickness of about 1 μm is obtained in the non-window area of the mask;

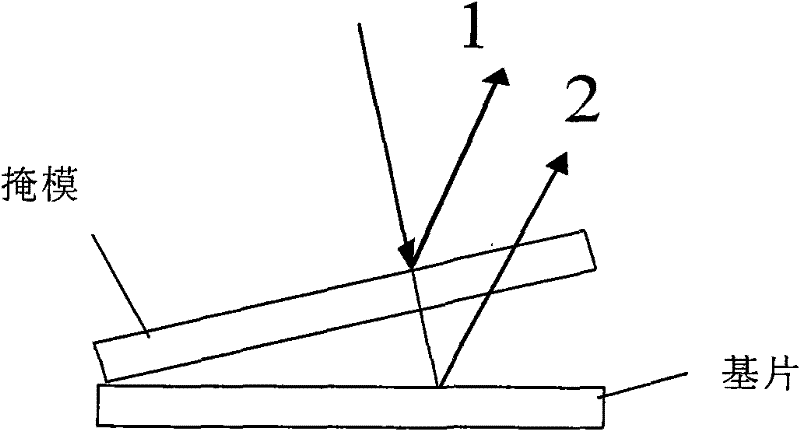

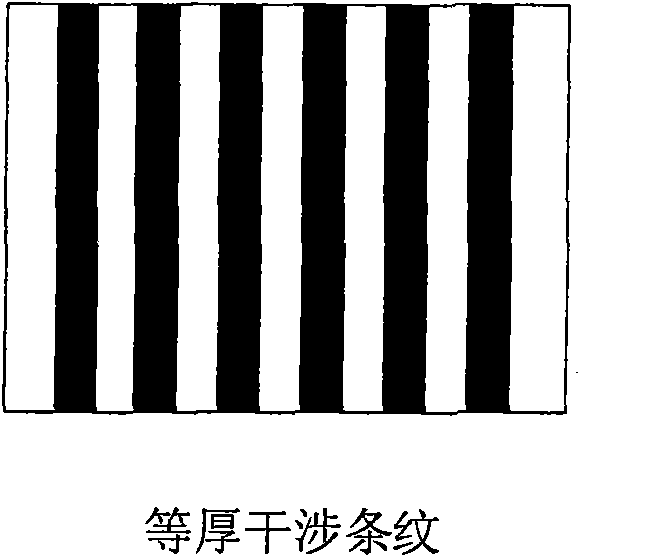

[0027] (2) Place the sample coated with photoresist on the fixture, with the photoresist facing up; then place the st...

example 210

[0030] Example 2.10μm gap control (photoresist material, exposure process)

[0031] (1) Fabrication of 10μm steps

[0032]Take a piece of silicon nitride mask (7.5mm×7.5mm silicon nitride wafer, 3mm×3mm thin film window), put it on the adhesive machine, drop the photoresist solution AZ9260, and spin coat at 500 rpm Coating for 10 seconds, spin coating at 1500 rpm for 30 seconds, then place the silicon nitride mask coated with AZ9260 on a hot stage at 100 degrees, bake for 10 minutes, and dry the solvent in AZ9260 to obtain the thickness AZ9260 photoresist layer of about 10 μm; use a photomask with a window size of 3mm×3mm or larger to perform UV exposure on the silicon nitride mask, use g-line exposure for 90 seconds, and then develop with 6‰ NaOH for 3 minutes , rinse with deionized water for 1 minute, remove the photoresist of the window, and obtain a photoresist step with a thickness of about 10 μm in the non-window area of the mask;

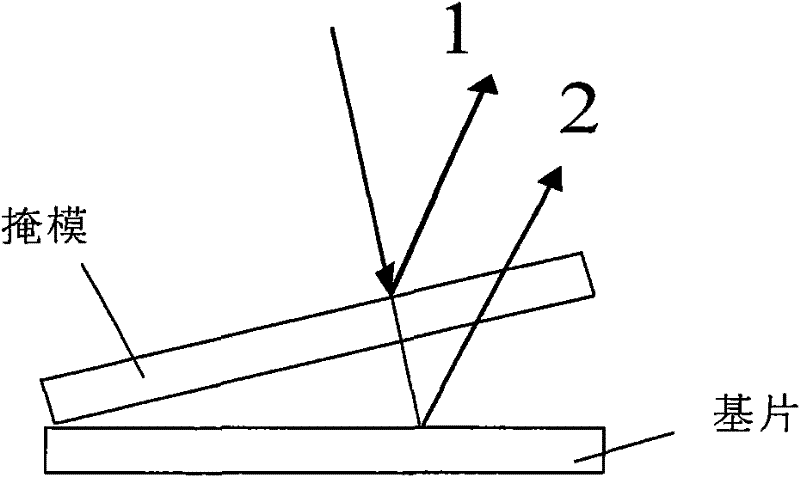

[0033] (2) Place the sample coated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com