Growing method of gallium nitride

A growth method, gallium nitride technology, applied in the field of gallium nitride epitaxy, can solve the problems of difficult to obtain high-quality device-grade gallium nitride materials and gallium nitride materials, and achieve low-cost and highly controllable growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

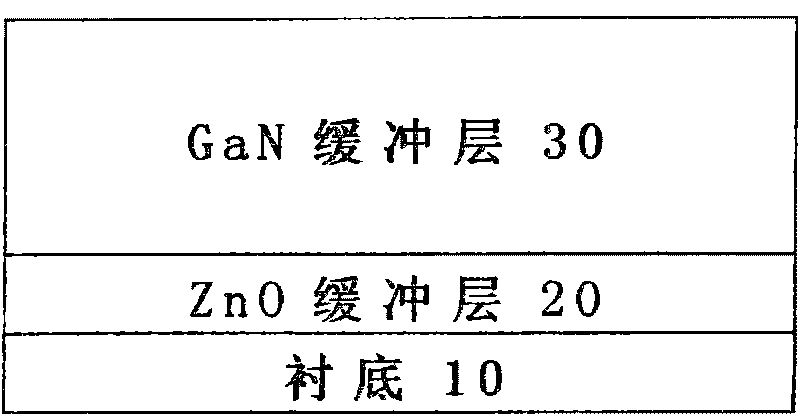

[0028] Please refer to figure 1 As shown, firstly, a zinc oxide buffer layer 20 is grown on the m-plane sapphire substrate 10 by magnetron sputtering, and the thickness of the buffer layer is 200nm. For comparison, we also choose not to grow the zinc oxide buffer layer 20 at the same time. The m-face sapphire was used for experimental control;

[0029] Then, a gallium nitride epitaxial layer 30 of 50 microns was grown on the sapphire with and without the zinc oxide buffer layer 20 grown by the HVPE method. In order to avoid the reaction of zinc oxide in a reducing atmosphere, nitrogen was used as the carrier gas;

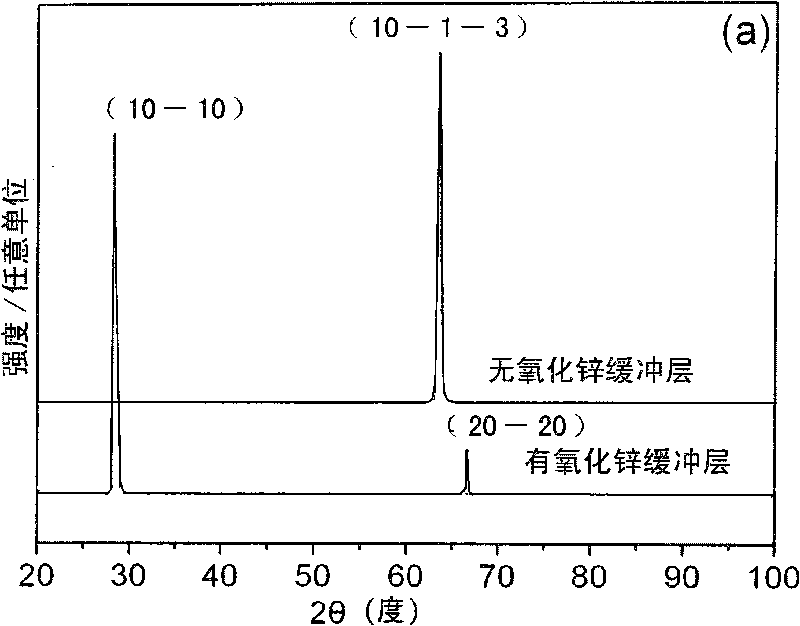

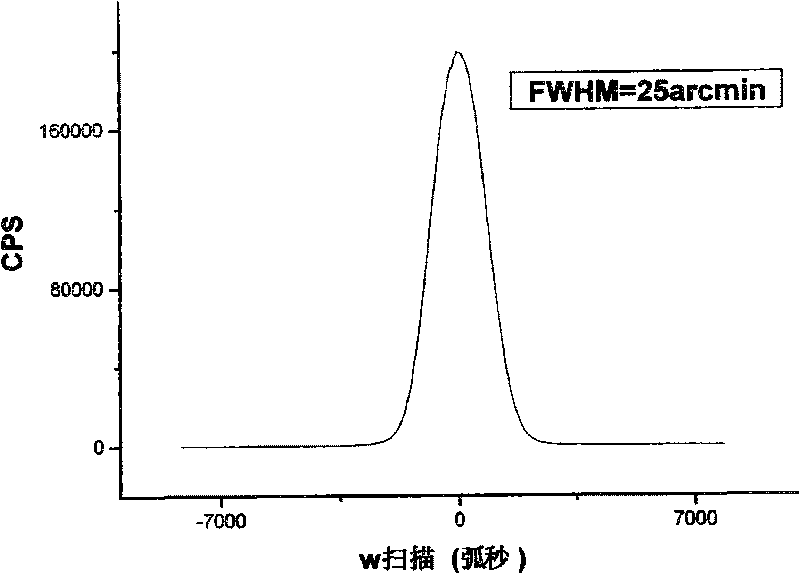

[0030] The grown gallium nitride was subsequently characterized by XRD, and it was found that the gallium nitride epitaxial layer 30 without the zinc oxide buffer layer 20 had a (10-1-3) plane orientation; while the gallium nitride grown with the zinc oxide buffer layer 20 The orientation of the epitaxial layer 30 is the m(10-10) plane orientation, (such as figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com