Method for production of processed livestock meet food or processed sea food, and enzyme preparation for improvement of processed livestock meet food or processed sea food

A technology of processed food and manufacturing method, which is applied in the field of the manufacture of processed animal meat or aquatic product processed food and the enzyme preparation used for the modification of animal meat processed food or aquatic product processed food, and can solve the problems of food taste design restrictions and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

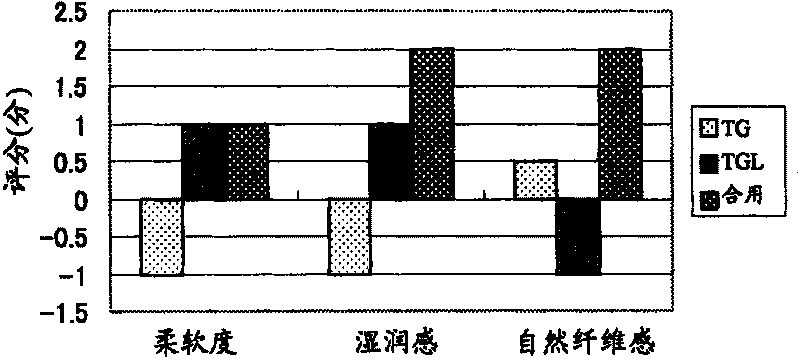

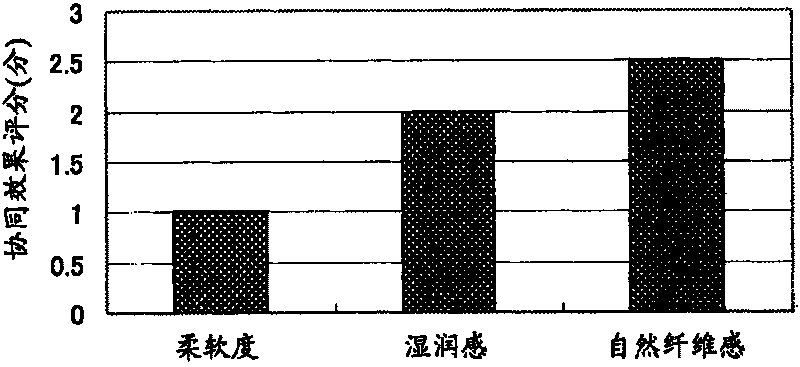

[0033] Example 1: Fried Chicken

[0034] After removing the skin and fat of chicken thigh meat (a whole domestic piece of meat), soak it in a dipping sauce equivalent to 120% of the meat (20 parts by weight for 100 parts by weight of meat) (equivalent to 120% of the meat) の洛け込み油に洛けin a marinade liquid of 120% to meat), turn over at 5°C for 2 hours. When turning over, use "3-joint tumbler" (manufactured by TOUNICHI). The compounding ratio of the dipping juice is as shown in Table 1, and the enzyme uses "transglucosidase L" (produced by Amano Enzyme Co., Ltd.) (hereinafter referred to as TGL), as "ACTIVA" TG of transglutaminase preparation (Ajinomoto Co., Ltd. production) (hereinafter referred to as TG), and "Matsutani Momiji" (manufactured by Matsutani Chemical Industry Co., Ltd.) was used for the processed starch. The test groups were the control group without enzyme addition, the group with only TG added, the group with only TGL added, and the combined group with TG and TGL ...

Embodiment 2

[0038] Example 2: Fried Chicken

[0039] After removing the skin and fat from the chicken thigh meat (a whole piece of domestic meat), cut it into small pieces of 23-25g each. Mix and dissolve the enzyme preparation comprising enzyme and starch in water to prepare the dipping juice of the composition shown in Table 2, add 150% water (100 parts by weight of meat corresponds to 50 parts of dipping juice) to soak the meat slices, and use a small rotary The cylinder (manufactured by TONICHI MFG. Co., Ltd.) was tumbled under vacuum at 5°C and 34 rpm for 30 minutes.

[0040] Table 2: Composition of maceration juice, sensory evaluation results, yield of trial product

[0041]

[0042] As the enzyme preparation, TGL, TG, and waxy corn starch "MD" (manufactured by Nippon Food Chemicals Co., Ltd.) were used as starch. After turning it over, let it stand at 5°C for 30 minutes, then sprinkle it with Arrowhead mushroom powder, fry it at 175°C for 4 minutes and 30 seconds in a fryer "H...

Embodiment 3

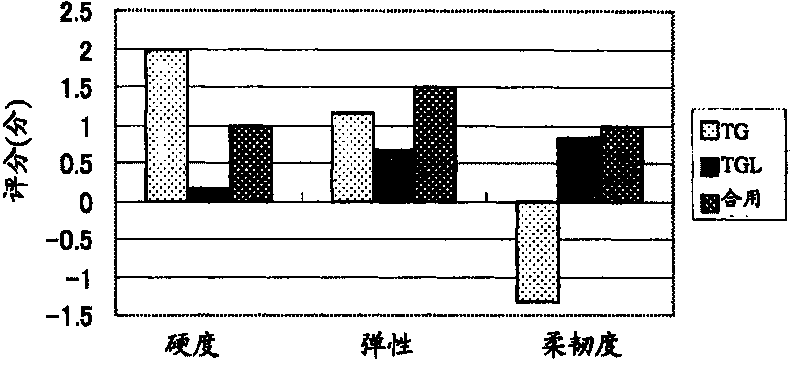

[0043] Example 3: Sausage

[0044] Thaw frozen pork foreleg (from Denmark), mince the lean meat part, add salt (Table 3 B) and part of crushed ice according to the compounding in Table 3, use a low-noise cutting machine "MK13" ( MULLER company) for cutting. When the temperature of the trial product reached 4°C, seasonings (C in Table 3) and some crushed ice were added and then cut. When the temperature reached 6°C, pork back fat was added, and when the temperature reached 10°C, proteins (C in Table 3 A), enzyme and remaining crushed ice, cut. The test groups were the control group without enzyme addition, the group with only TG added, the group with only TGL added, and the combined group with TG and TGL added together, a total of 4 test groups. In addition, the amount of TGL in the combination group was about 800 units per 1 unit of TG. It was taken out when it reached 12° C., and packaged in a collagen package “NIPPI CASING” (manufactured by NIPPI COLLAGEN Industries, Ltd....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com