Method for producing fruit granule-containing dairy products

A technology for fruit granules and production methods, applied in dairy products, milk preparations, applications, etc., can solve the problems of destroying fruit pulp granules, destroying the integrity of fruit granules, etc., so as to reduce shearing effect, reduce the degree of damage, and ensure continuous sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

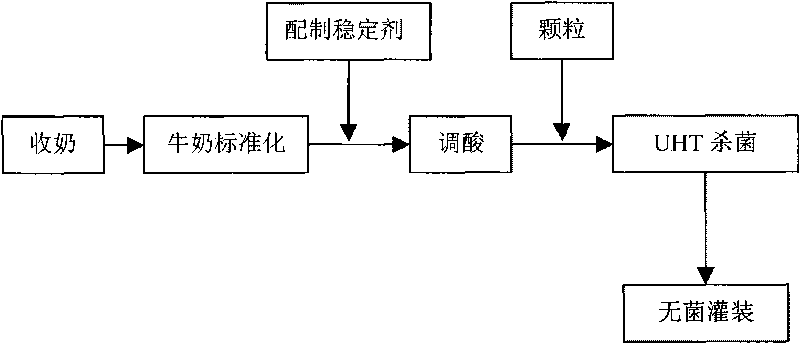

Method used

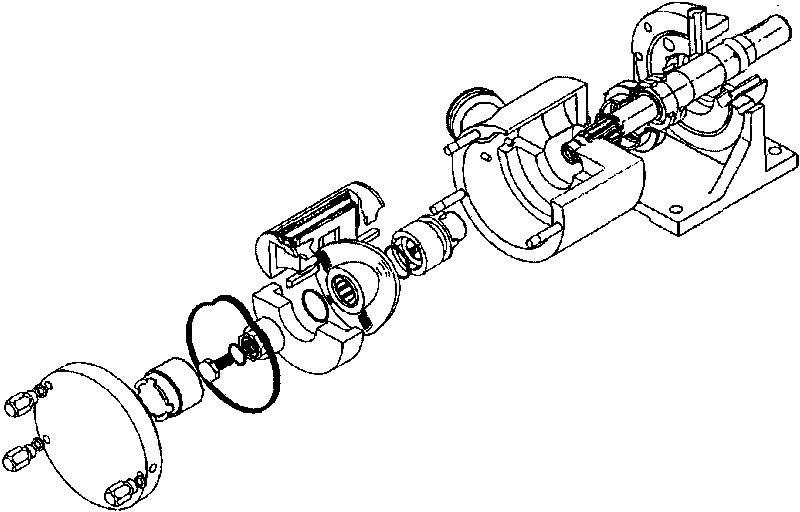

Image

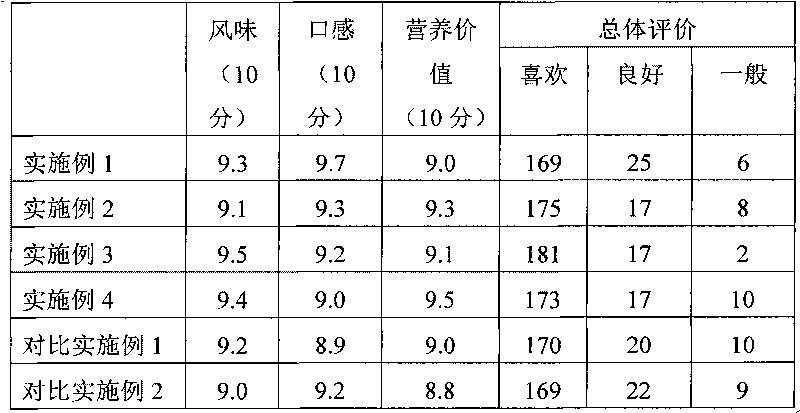

Examples

Embodiment 1

[0026] Embodiment 1 prepares liquid milk beverage containing apple particles

[0027] Milk: 42.0 parts, white sugar: 9.5 parts, apple granules: 5.0 parts [particle size (cm): 5×5×5], stabilizer combination I: 0.45 parts (0.3 parts of pectin, 0.1 parts of sodium alginate, two Acetyl tartrate monoglyceride 0.05 parts), sodium citrate: 0.08 parts, food flavor: 0.01 parts, citric acid: 0.03 parts, ingredient water: 42.93 parts.

[0028] Specific steps are as follows:

[0029] (a) The raw milk whose temperature does not exceed 8°C is used to remove mechanical impurities in the raw milk through the milk cleaning process; or fermented milk is used as the equivalent of milk to produce fermented dairy products;

[0030] (b) prepare stabilizer solution: water and stabilizer combination I are prepared as 70:1 by weight;

[0031] (c) mixing the acidity regulator and water in a ratio of 1 to 100 and stirring evenly;

[0032] (d) mix the above three kinds of raw materials in (a) and (b),...

Embodiment 2

[0036] Embodiment 2 prepares the liquid milk drink containing pear particle

[0037] Milk: 35 parts, white sugar: 12 parts, pear granules: 10.0 parts [particle size (cm): 3×3×3], stabilizer combination II: 0.3 parts (sodium alginate 0.2 part, propylene glycol alginate 0.1 part ), citric acid: 0.02 parts, lactic acid: 0.01 parts, edible essence: 0.08 parts, and batching water 42.59 parts.

[0038] Specific steps are as follows:

[0039] (a) Use raw milk whose temperature does not exceed 8°C to remove mechanical impurities in the raw milk through a milk cleaning process, or use fermented milk as the equivalent of milk to produce fermented dairy products;

[0040] (b) preparing stabilizer solution: water and stabilizer are prepared in a weight ratio of 80:1;

[0041] (c) mixing the acidity regulator and water in a ratio of 1 to 110 and stirring evenly;

[0042] (d) Mix the above three raw materials in (a) and (b), adjust the pH to 3.8 with the solution in (c), and constant vol...

Embodiment 3

[0046] Embodiment 3 prepares the liquid milk beverage containing pomelo capsule

[0047] Milk: 50 parts, white sugar: 8 parts, pomelo capsule: 12 parts [particle size (cm): 2×2×10], stabilizer combination III: 0.6 (propylene glycol alginate: 0.5 part, pectin 0.1 part) , malic acid: 0.18 parts, edible essence: 0.07 parts, and ingredient water 29.15 parts.

[0048] Specific steps are as follows:

[0049] (a) Use raw milk whose temperature does not exceed 8°C to remove mechanical impurities in the raw milk through a milk cleaning process, or use fermented milk as the equivalent of milk to produce fermented dairy products;

[0050] (b) preparing stabilizer solution: water and stabilizer are prepared in a ratio of 30:1 by weight;

[0051] (c) mixing the acidity regulator and water in a ratio of 1 to 50 and stirring evenly;

[0052] (d) Mix the three raw materials in the above (a) and (b) evenly, adjust the pH to 4.2 with the solution in (c), and constant volume;

[0053](e) Adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com