Method for bulking crop straws by using solar energy

A technology for crop straw and puffing treatment, applied in the fields of application, food science, animal feed, etc., can solve the problems of restricting the development of value-added utilization of straw, insufficient biochemical treatment, and inability to obtain biomass raw materials, so as to improve the value of industrial raw materials, The effect of solving the competition between humans and animals for food and good disinfection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

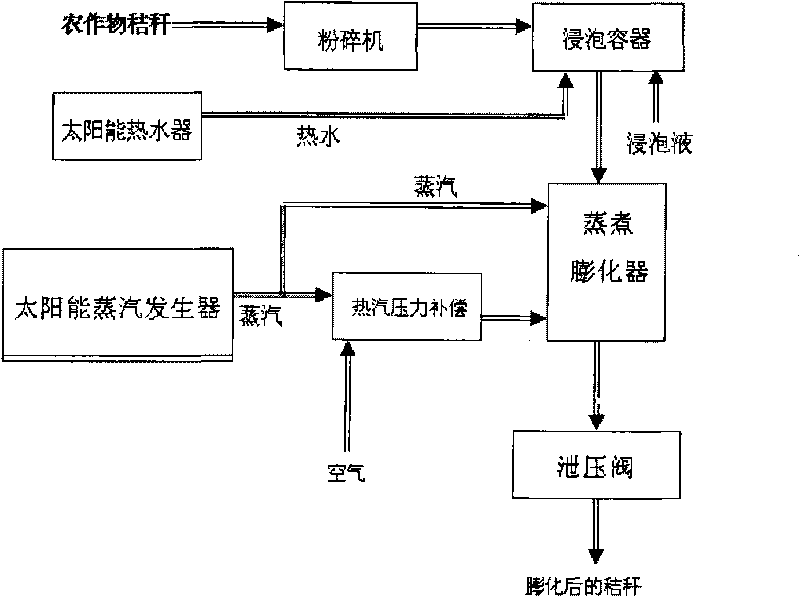

[0030] A. After the crop stalks are removed, air-dry to dry, and then pulverize with a conventional pulverizer in the prior art to obtain straw powder;

[0031] B, straw powder is sent in the conventional soaking container in the prior art, and by the mass ratio of 40% of the total amount of straw, add the ammoniacal liquor and urea aqueous solution that temperature is 20 ℃ in straw powder, this aqueous solution is to use existing The hot water heated by the conventional solar thermal heater in the technology is prepared and soaked for 30 hours, wherein the nitrogen-containing ratio of ammonia water and urea aqueous solution is a mass ratio of 0.3%;

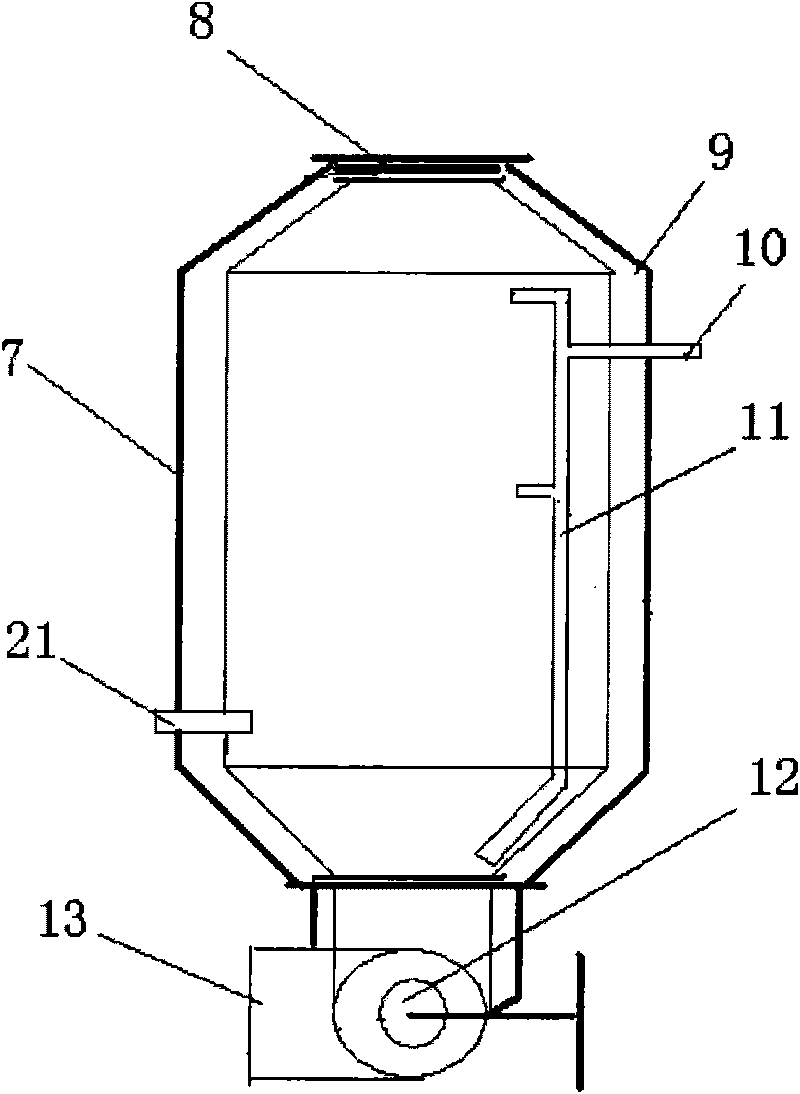

[0032] C. Send the stalk powder soaked in step B into the cooking puffing device, feed the steam generated by the solar steam generator until the pressure is 0.4MPa, the temperature is 135°C, and cooking and sterilizing for 30 minutes;

[0033] D. Open the pressure relief valve at the bottom of the cooking puffing device to insta...

Embodiment 2

[0035] A. After the crop stalks are removed, air-dry to dry, and then pulverize with a conventional pulverizer in the prior art to obtain straw powder;

[0036] B, straw powder is sent in the conventional soaking container in the prior art, and by the mass ratio of 50% of straw total amount, add the ammoniacal liquor and urea aqueous solution that temperature is 30 ℃ in straw powder, this aqueous solution is to use existing The hot water heated by the conventional solar heat heater in the technology is prepared and soaked for 20 hours, wherein the nitrogen-containing ratio of ammonia water and urea aqueous solution is a mass ratio of 3%;

[0037] C. Send the straw powder soaked in step B into the cooking puffing device, and feed the steam generated by the solar steam generator and the compressed hot gas generated by the hot gas pressure compensator until the pressure is 1 MPa and the temperature is 180 ° C. Cook and sterilize 10 minutes;

[0038] D. Open the pressure relief v...

Embodiment 3

[0040] A. After the crop stalks are removed, air-dry to dry, and then pulverize with a conventional pulverizer in the prior art to obtain straw powder;

[0041] B, the stalk powder is sent into the conventional immersion container in the prior art, by the quality of 45% of the stalk total amount, in the above-mentioned stalk powder, adding temperature is 15 ℃, concentration is the sulfuric acid aqueous solution of 1% mass ratio, this aqueous solution Prepared with hot water heated by conventional solar heaters in the prior art, soaked for 30 hours;

[0042] C. Put the straw powder soaked in step B into the cooking puffing device, feed the steam generated by the solar steam generator, and at the same time, fill it with the compressed hot gas generated by the hot gas pressure compensator until the pressure is 0.8 MPa and the temperature is 150°C, cook and sterilize for 20 minutes;

[0043] D. Open the pressure relief valve at the bottom of the cooking puffing device, and instan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com