Preparation method for cross-linking polyvinyl alcohol furfural nanofiltration membrane

A technology of polyvinyl furfural and polyvinyl alcohol, which is applied in the field of preparation of hydrophilic charged membranes, can solve problems such as difficulty in regulating the filling amount of nano-silica, and achieve novel preparation methods, good selectivity, and good affinity water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Heat and stir 3% polyvinyl alcohol (PVA) and appropriate amount of water in a flask until the solution becomes transparent, add hydrochloric acid dropwise to adjust the pH value, add 10 mL of furfural (Fu), and stir until transparent. Add 5g of maleic anhydride dropwise, until it dissolves completely, filter the obtained PVFu solution to remove impurities, degas it with a vacuum pump for 2 hours, then pour it into a metal frame with a porous polysulfone base film, and keep it for 3 Minutes, use a rubber roller to remove the PVFu solution remaining on the surface of the polysulfone, vacuum dry at 100°C for 2 hours and take it out to obtain a PVFu nanofiltration membrane. Wherein the porous polysulfone base membrane is selected from polysulfone and polyethersulfone.

[0030] With 2000ppm (one millionth of the mass concentration) of Na 2 SO 4 , NaCl, PEG200, MgCl 2 , PEG600 aqueous solution, test the initial performance of the membrane under the pressure of 1MPa. The o...

Embodiment 2-5

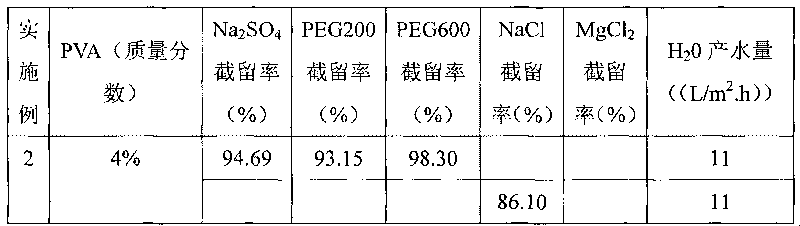

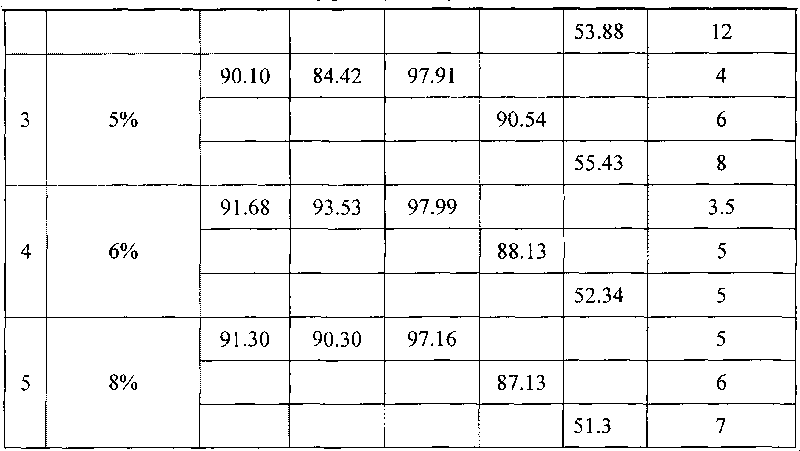

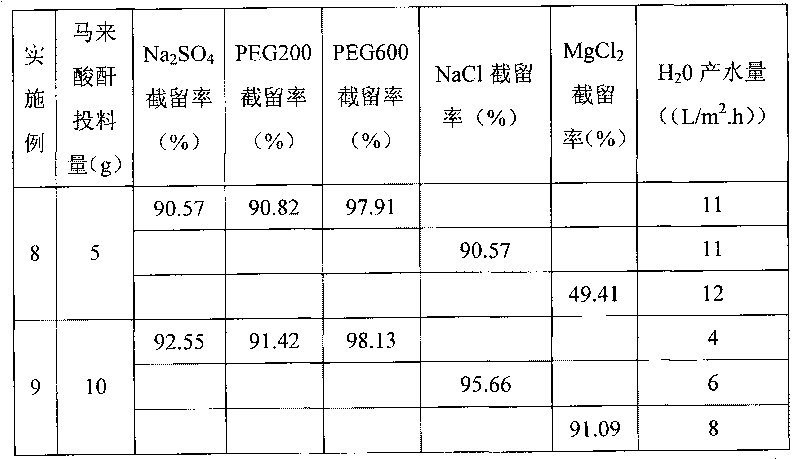

[0032] Keep the addition of furfural (Fu) 10mL and maleic anhydride 5g unchanged, change the feeding amount of polyvinyl alcohol, other operating conditions are all the same as in Example 1, and the results are as shown in table 1

[0033] Table 1

[0034]

[0035]

Embodiment 6

[0037] Heat and stir 5% polyvinyl alcohol (PVA) and appropriate amount of water in a flask until the solution becomes transparent, add hydrochloric acid dropwise to adjust the pH value, add 10 mL of furfural (Fu), and stir until transparent. Filter the obtained PVFu solution to remove impurities, use a vacuum pump to defoam for 2 hours, then pour it into a metal frame with a porous polysulfone bottom film, keep it for 3 minutes, and use a rubber roller to remove the residue on the surface of polysulfone. The PVFu solution was vacuum-dried at 90° C. for 2 hours and taken out to obtain a PVFu nanofiltration membrane. Wherein the porous polysulfone base membrane is selected from polysulfone and polyethersulfone.

[0038] With 2000ppm (one millionth of the mass concentration) of Na 2 SO 4 , NaCl, PEG200, MgCl 2 , PEG600 aqueous solution, test the initial performance of the membrane under the pressure of 1MPa. The obtained results are as follows: 2 SO 4 The desalination rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com