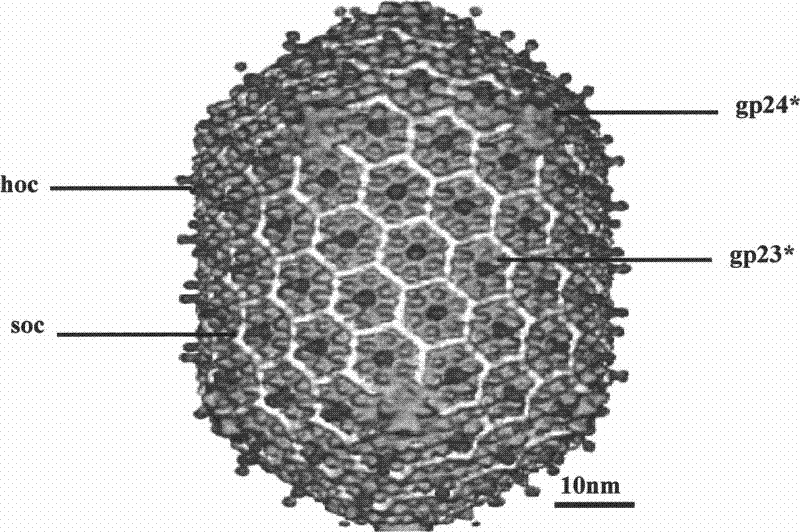

Preparation method of T4 bacteriophage supported precious metal nano-particle catalyst

A nanoparticle and bacteriophage technology, applied in the field of catalysis, can solve the problems of reducing catalytic activity and increasing production cost, and achieve the effects of high electrocatalytic activity, reduced economic cost and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Proliferation and enrichment of T4 phage

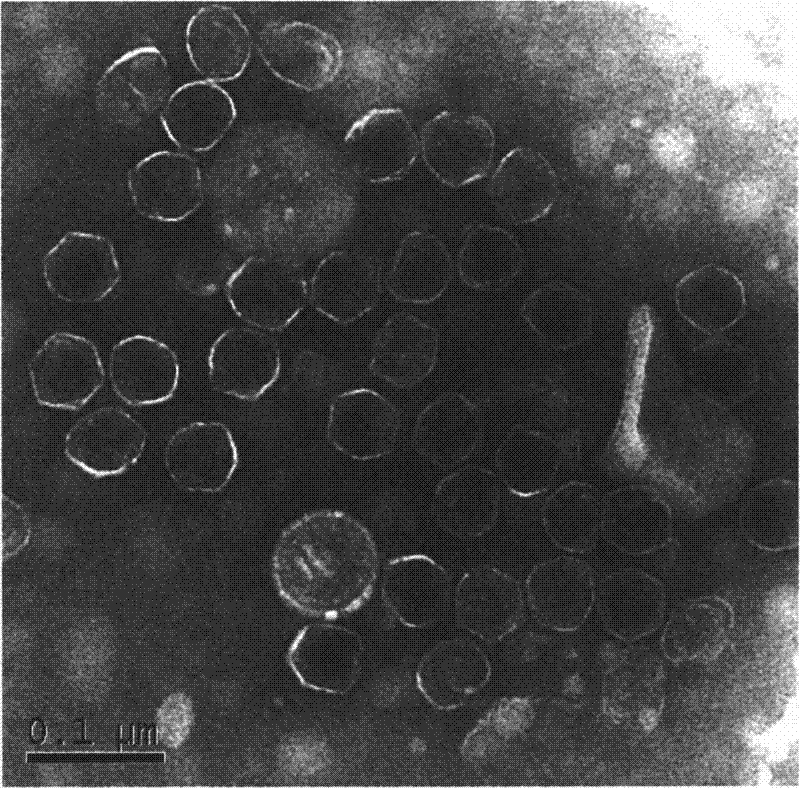

[0028] The T4 phage was inserted into 50 mL of pre-incubated E. coli suspension with a concentration of 10 mg / mL, and cultured on a shaking table at 37° C. at 120 r / min for 12 h. The obtained suspension containing T4 phage and Escherichia coli fragments was centrifuged at 4°C for 15 min at 4000, 5000, and 6000 r / min in sequence, and the precipitate was discarded each time, and the supernatant was taken. Then the supernatant containing pure T4 phage was ultracentrifuged at 4°C and 45000r / min for 3h. The obtained T4 phage precipitate was collected and dispersed in 2.5 mL deionized water. Its morphology was observed under a transmission electron microscope. figure 2 .

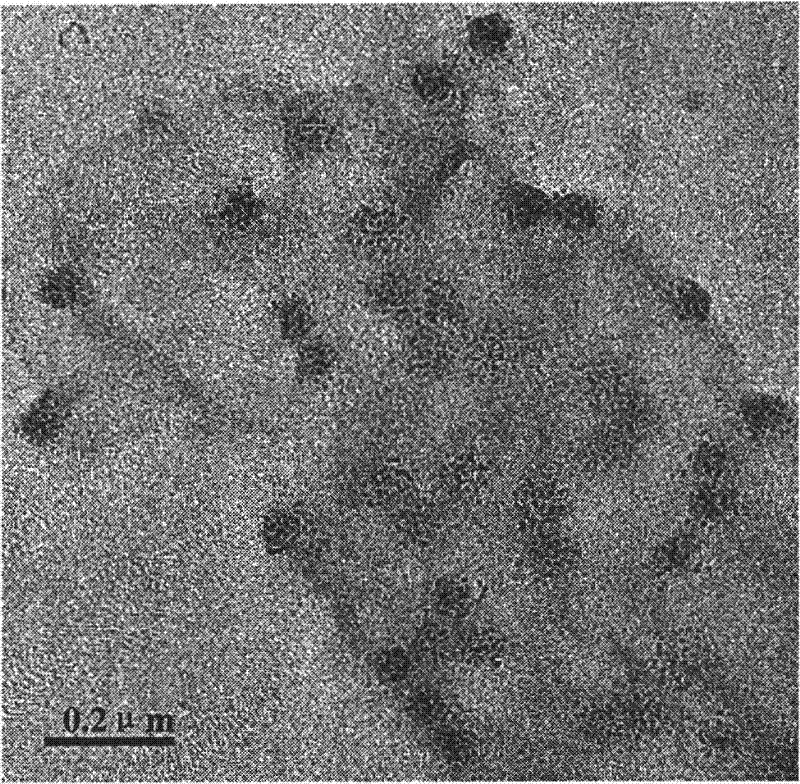

[0029] 2. Preparation of T4 phage-loaded Pt nanoparticles catalyst

[0030] Add 200 μL of the enriched T4 phage suspension to 200 μL of 5 mM PtCl 4 Mix well in the solution, and incubate at 4°C for 10 hours on a shaker at 60 r / min. Afterwards, ultracentri...

Embodiment 2

[0032] 1. Proliferation and enrichment of T4 phage

[0033] See step 1 of Embodiment 1, the process is exactly the same.

[0034]2. Preparation of T4 phage-loaded Rh nanoparticles catalyst

[0035] Add 200 μL of the enriched T4 phage suspension to 200 μL of 5 mM RhCl 3 Mix well in the solution, and incubate at 4°C for 10 hours on a shaker at 60 r / min. Afterwards, ultracentrifuge at 4°C, 45000r / min for 3h, collect the obtained precipitate, and disperse in 200μL deionized water. Then add 75 μL freshly prepared 5 mM NaBH dropwise 4 solution, that is, the T4 phage-loaded Rh nanoparticle catalyst was prepared.

Embodiment 3

[0037] 1. Proliferation and enrichment of T4 phage

[0038] See step 1 of Embodiment 1, the process is exactly the same.

[0039] 2. Preparation of T4 phage-loaded Pd nanoparticles catalyst

[0040] Add 200 μL of the enriched T4 phage suspension to 200 μL of 1 mM PdCl 2 Mix well in the solution, and incubate at 4°C for 10 hours on a shaker at 60 r / min. Afterwards, ultracentrifuge at 4°C, 45000r / min for 3h, collect the obtained precipitate, and disperse in 200μL deionized water. Then add 60 μL freshly prepared 5 mM NaBH dropwise 4 solution, that is, the T4 phage-loaded Pd nanoparticle catalyst was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com