Porous membrane material continuous radiation grafting method and support equipment therefor

A technology of radiation grafting and porous membrane is applied in the field of equipment matched with the continuous radiation grafting method, which can solve the problems of difficult industrialization of the pre-radiation grafting process, damage to the substrate, and large radiation absorbed dose of the substrate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

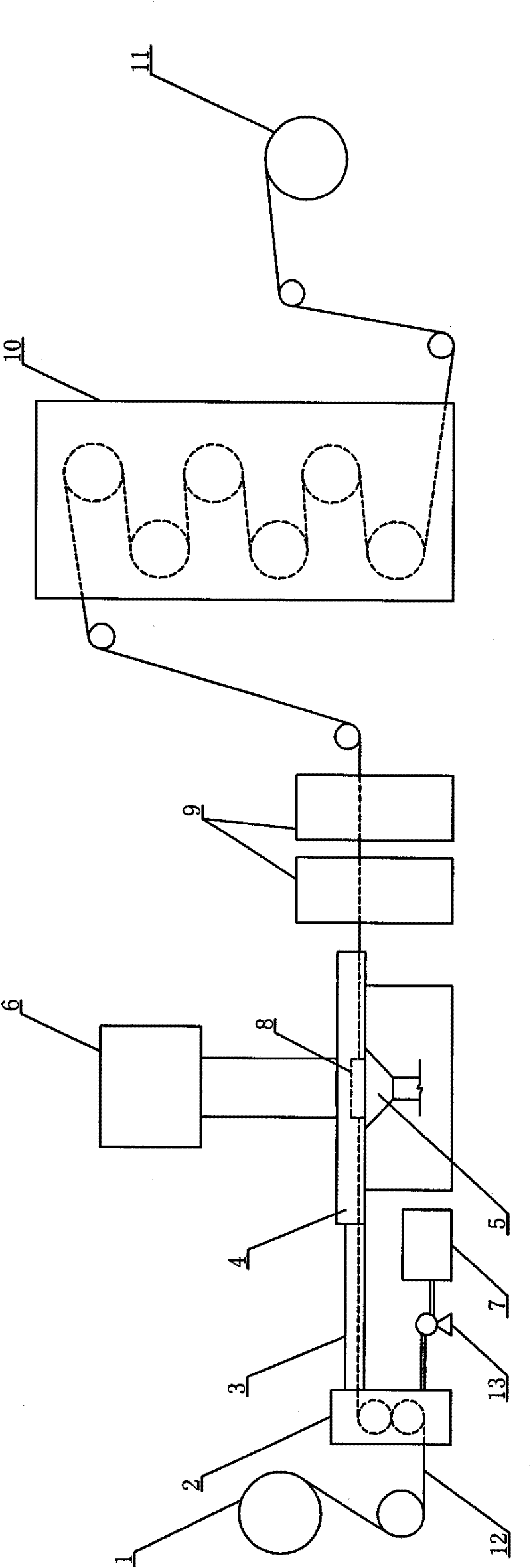

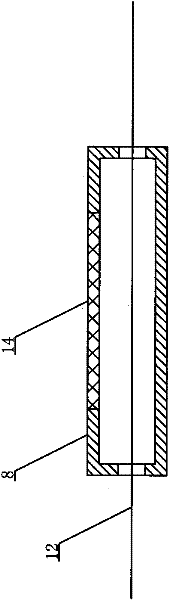

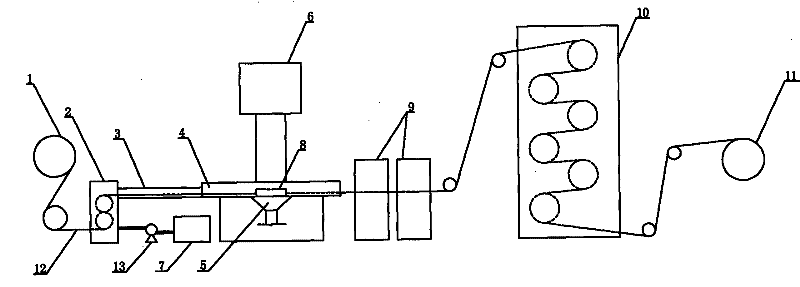

[0029] like figure 1 and figure 2 As shown, the supporting equipment for the continuous radiation grafting method of porous membrane materials mainly includes an unwinder 1, a coating device 2, an irradiation chamber 4 connected to an electron accelerator 6, a washing device 9, a drying device 10, and a winder 11 and the guide device (composed of a series of guide rollers in this embodiment) that runs through each part in turn. The irradiation room 4 is provided with an irradiation box 8 with a titanium window 14. The electrons are accelerated by the electron accelerator 6 and injected into the irradiation room 4, and then injected into the irradiation box 8 through the titanium window 14. The irradiation box 8 can provide The porous membrane material 12 passes through the inside thereof. The lower part of the irradiation chamber 4 is equipped with an exhaust device 5 to remove ozone and heat generated by radiation in time. The coating device 2 relies on the storage tank 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com