Heat-reflecting insulating coating for outer surface of building and preparation method thereof

A technology for heat-insulating coatings and outer surfaces, which is applied in the field of heat-reflecting heat-insulating coatings for building exterior surfaces and its preparation, and can solve the problems of less heat-reflecting functional pigments, affecting solar heat reflectivity, and adding too many fillers, etc. Achieve the effect of simple and convenient construction process, reduce heat conduction, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to describe in detail the technical content, achieved objectives and effects of the present invention, the following will be described in detail in combination with the embodiments.

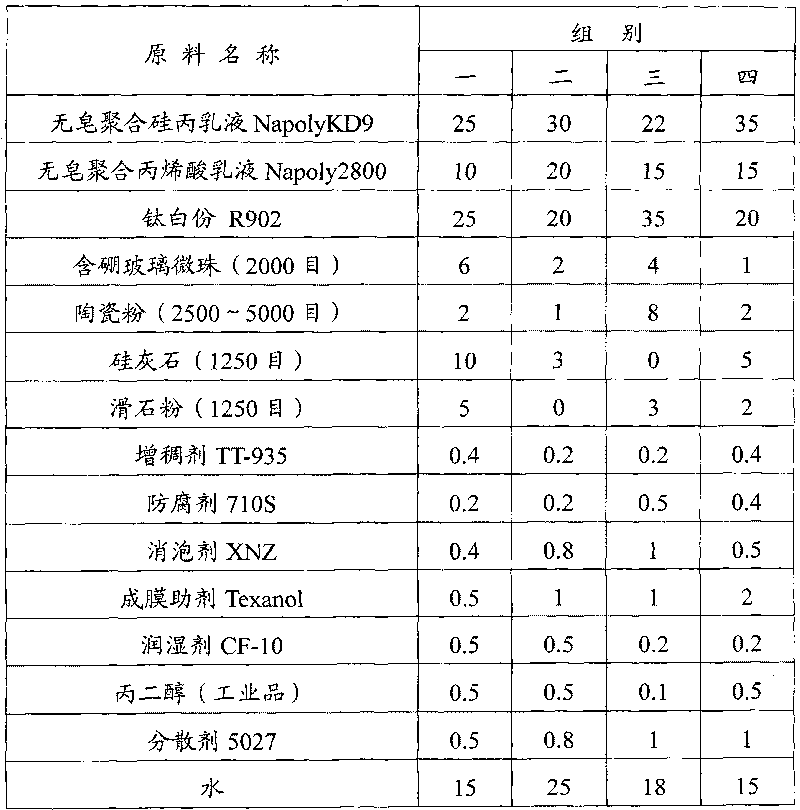

[0046] Prepare the raw materials according to the formula and the number of servings described in Table 1:

[0047]

[0048] Table 1

[0049] The soap-free polymerized silicon-acrylic emulsion described in this example is NapolyKD9 from National Starch Chemical Company of the United States, and the soap-free polymerized acrylic acid emulsion is Napoly2800 from National Starch Chemical Company of the United States. In practical applications, the water-based soap-free polymeric copolymer emulsion can also use the following models of American National Starch Chemical Company: NapolyKD6, NapolyAD36, NapolyAD66 or DirtshieldK2 of American Rohm and Haas Company or Bailimo product AC-1360.

[0050] The model of titanium dioxide described in this embodiment is R-902 from DuPont Compan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com