Method for carrying out immersion plating on marine climate-resisting engineering parts

A marine climate and parts technology, applied in hot dip plating process, metal material coating process, coating and other directions, can solve the problems of difficult surface shape, size control, difficult to handle large area parts, high vapor deposition cost, and achieve material The effect of low cost, improved air scouring and erosion ability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) After the parts are cleaned and degreased, they are treated with pickling and rust removal, and rinsed with deionized water.

[0037] (2) Activation treatment in a mixed solution of ethylene glycol 600ml / L, acid ammonium fluoride 45g / L, nickel chloride 30g / L, boric acid 60g / L, lactic acid 35ml / L, acetic acid 230ml / L, temperature 40°C , time 40min, rinse with deionized water, and dry.

[0038] (3) Put the parts treated in (1) to (2) into the atmosphere protection furnace and preheat at 500°C for 20 minutes.

[0039] (4) In the atmosphere protection melting furnace, immerse the preheated steel parts in the plating solution for 1 minute, and rotate the parts during the immersion process.

Embodiment 2

[0041] (1) After the parts are cleaned and degreased, they are treated with pickling and rust removal, and rinsed with deionized water.

[0042] (2) Activation treatment in a mixed solution of ethylene glycol 900ml / L, acidic ammonium fluoride 25g / L, nickel chloride 10g / L, boric acid 20g / L, lactic acid 10ml / L, acetic acid 70ml / L, temperature 50°C , time 35min, rinse with deionized water, and dry.

[0043] (3) Put the parts treated in (1) to (2) into the atmosphere protection furnace, and preheat at 600°C for 15 minutes.

[0044] (4) In the atmosphere protection melting furnace, immerse the preheated steel parts in the plating solution for 3 minutes, and rotate the parts during the immersion process.

Embodiment 3

[0046] (1) After the parts are cleaned and degreased, they are treated with pickling and rust removal, and rinsed with deionized water.

[0047](2) Activation treatment in a mixed solution of ethylene glycol 700ml / L, acid ammonium fluoride 35g / L, nickel chloride 20g / L, boric acid 50g / L, lactic acid 20ml / L, acetic acid 180ml / L, temperature 60°C , time 30min. Rinse with deionized water and dry.

[0048] (3) Put the parts treated in (1) to (2) into the atmosphere protection furnace, and preheat at 650°C for 10 minutes.

[0049] (5) In the atmosphere protection melting furnace, immerse the preheated steel parts in the plating solution for 5 minutes, and rotate the parts during the immersion process.

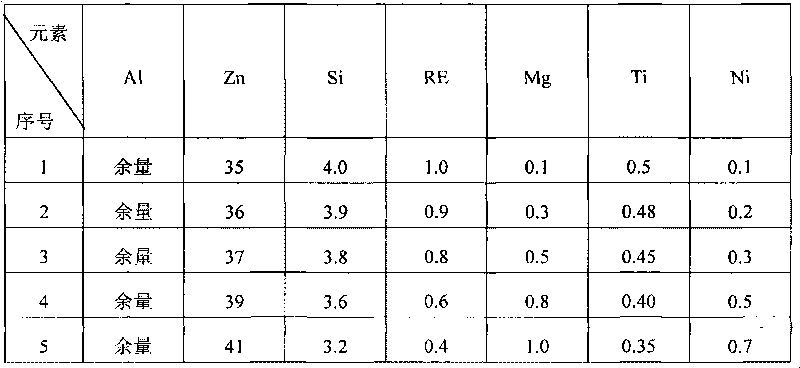

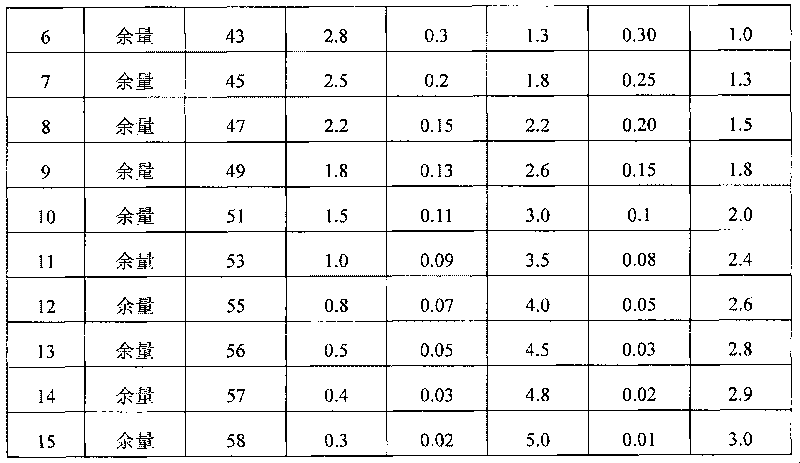

[0050] Wherein, the composition and content of the plating solution in Examples 1-3 are shown in Table 1 below, and it should be noted that in Table 1, only some preferred embodiments of the plating solution of the present invention are provided, although the microalloy of Table 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com