Carbon compound cathode material for ultracapacitor battery

A technology for supercapacitor batteries and anode materials, applied in the field of electrochemistry, can solve the problems affecting the high rate of supercapacitor batteries, large capacity and high energy density performance, inability to maximize supercapacitor batteries, poor conductivity of lithium titanium oxide, etc. problems, to achieve good lithium ion intercalation/deintercalation performance, good electric double layer energy storage and lithium ion de/intercalation energy storage characteristics, good high rate charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

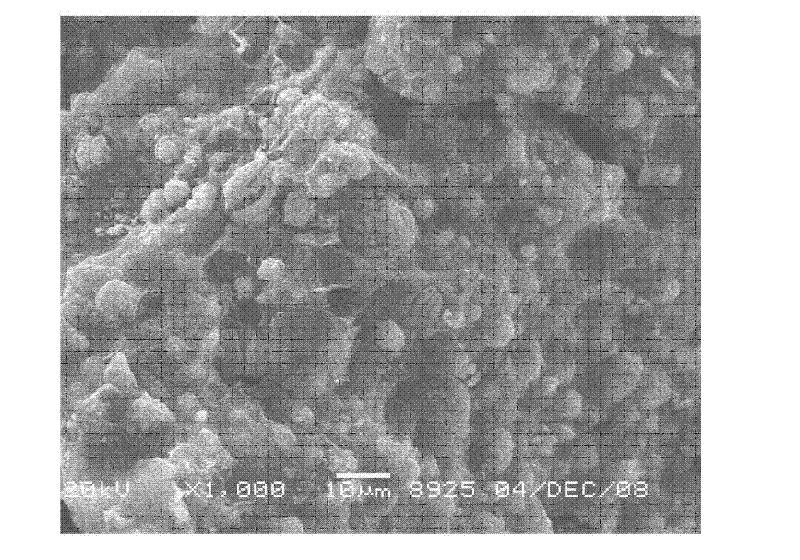

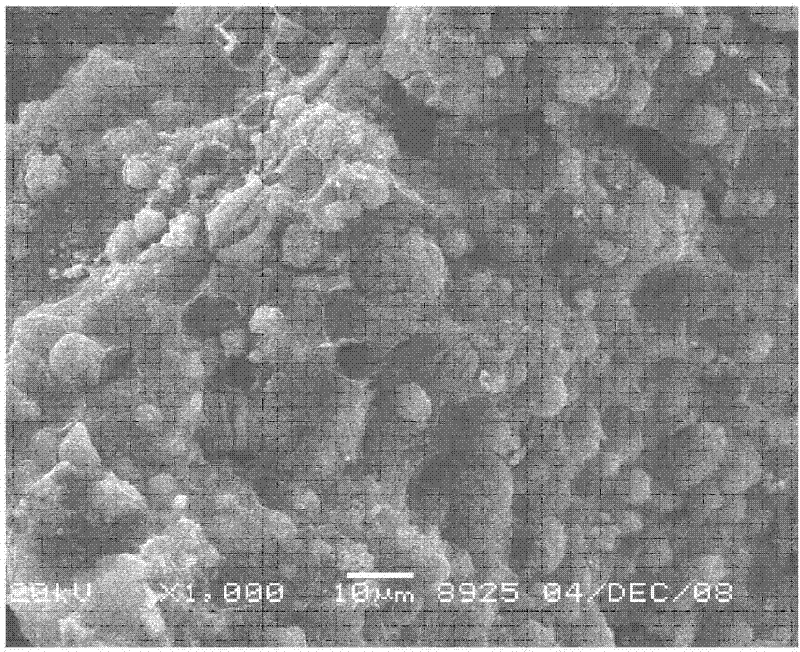

Image

Examples

Embodiment 1

[0028] 1. Add 100 grams of surface-nanoized natural graphite, 100 grams of resin, and 300 g of NaOH template agent with a particle size distribution of 1-2 nm, medium particle 5-50 nm, and large particle 60-100 nm, and add them to methanol for mechanical ball milling for 1 hour, then , and evaporated to dryness at a low temperature of 50-60°C to obtain a precursor;

[0029] 2. Heat the prepared precursor to 200°C at a heating rate of 5-10°C / min under an ammonia protective atmosphere, and then heat it to 600°C at a heating rate of 1-5°C / min. , cooled with the furnace after constant temperature for 2h; the core-shell material of the three-dimensional hierarchical hole shell coated with micropores was obtained on the core material; detected by the nitrogen adsorption-desorption isotherm method, the pore size distribution of the micropores was: the pore size of the macropores was 50-120nm, medium pore diameter is 3-50nm, and small pore diameter is less than 2nm.

[0030] 3. Remov...

Embodiment 2

[0038] 1. Add 100 grams of surface-nanometerized artificial graphite, 100 grams of resin, and 300 g of NaOH template agent with a particle size distribution of 1-2 nm, medium particle 5-50 nm, and large particle 60-100 nm, and add them to methanol for mechanical ball milling for 1 hour, then , and evaporated to dryness at a low temperature of 50-60°C to obtain a precursor;

[0039] 2. Heat the prepared precursor to 300°C at a heating rate of 5-10°C / min under an ammonia protection atmosphere, and then heat it to 700°C at a heating rate of 1-5°C / min. , cooled with the furnace after constant temperature for 5h; the core-shell material of the three-dimensional hierarchical pore shell coated with micropores was obtained on the core material; the nitrogen adsorption-desorption isotherm method was used to detect the distribution of the micropore diameter: the macropore diameter was at 50-120nm, medium pore diameter is 3-50nm, and small pore diameter is less than 2nm.

[0040] 3. Rem...

Embodiment 3

[0048] 1. Add 100 grams of mesophase carbon microspheres (CMS) with surface nanometerization, 100 grams of resin, and 300 g of NaOH template agent with a particle size distribution of 1-2nm, 5-50nm, and 60-100nm, into methanol Mechanical ball milling for 1 hour, and then evaporating to dryness at a low temperature of 50-60°C to obtain the precursor;

[0049] 2. Heat the prepared precursor to 400°C at a heating rate of 5-10°C / min under an ammonia protection atmosphere, and then heat it to 800°C at a heating rate of 1-5°C / min. , cooled with the furnace after constant temperature for 10h; the core-shell material of the three-dimensional layered hole shell coated with micropores was obtained on the core material; detected by the nitrogen adsorption-desorption isotherm method, the pore size distribution of the micropores was: macropore pore size 50-120nm, medium pore diameter 3-50nm, small pore diameter less than 2nm.

[0050] 3. Removing the template agent: use dilute nitric acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com