Clear oral preparation with coenzyme Q10 and preparation method thereof

A technology for oral preparations and coenzymes, which is applied in the field of clear oral preparations containing coenzyme Q10 and its preparation, can solve the problems of poor stability, complicated preparation process and unsuitable storage for a long time, and achieves the effects of convenient storage, simple equipment and improved curative effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Coenzyme Q in this example 10 Components and percentages by weight of the semi-clear oral preparation composition are:

[0028] Coenzyme Q10: 4%, emulsifier: 8%, co-emulsifier: 1.5%, stabilizer: 5%.

[0029] The emulsifier is Span 60 and Tween 20 in a ratio of 1:1.

[0030] Described co-emulsifier is polyethylene glycol.

[0031] The stabilizer is sodium carboxymethylcellulose.

[0032] The preparation process of the coenzyme Q10 semi-clear oral preparation composition in this example is as follows: at a temperature of 80°C, first dissolve coenzyme Q10 in the emulsifier and co-emulsifier of the prescribed amount, add carboxymethyl cellulose sodium Aqueous solution, 30 minutes after high shearing at 2000rpm to prepare the final solution.

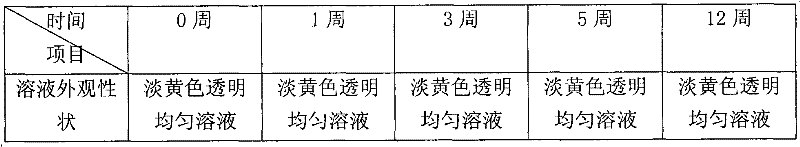

[0033] The beneficial effects of this embodiment are: (1) The appearance of the prepared microemulsion composition is light yellow and clear liquid. (2) After diluting the prepared microemulsion composition 50 times, the measured ...

Embodiment 2

[0035] Coenzyme Q in this example 10 Components and percentages by weight of the semi-clear oral preparation composition are:

[0036] Coenzyme Q10: 0.5%, emulsifier: 2%, co-emulsifier: 1.5%, stabilizer: 5%.

[0037] Described emulsifier is sucrose ester.

[0038] Described co-emulsifier is polyethylene glycol.

[0039] The stabilizer is sodium carboxymethylcellulose.

[0040] Coenzyme Q in this example 10 The preparation process of the semi-clear oral preparation composition is as follows: at a temperature of 35°C, coenzyme Q 10 Dissolve in the prescribed amount of sucrose ester and polyethylene glycol, add an aqueous solution containing sodium carboxymethylcellulose, and shear at 4000 rpm for 15 minutes to prepare the final solution.

[0041] The beneficial effects of this embodiment are: (1) The appearance of the prepared microemulsion composition is light yellow and clear liquid. (2) after the microemulsion composition of preparation is diluted 50 times, measure mean...

Embodiment 3

[0043] Coenzyme Q in this example 10 Components and percentages by weight of the semi-clear oral preparation composition are:

[0044] Coenzyme Q10: 2%, emulsifier: 5%, co-emulsifier: 10%, stabilizer: 5%.

[0045] The emulsifier is sucrose ester, the co-emulsifier is propylene glycol, and the stabilizer is xanthan gum.

[0046]Coenzyme Q in this example 10 The preparation process of the semi-clear oral preparation composition is as follows: at a temperature of 55°C, coenzyme Q 10 First dissolve in the prescribed amount of sucrose ester and polyethylene glycol, add an aqueous solution containing xanthan gum, and prepare the final solution after 10 minutes of high-speed shearing at 20,000 rpm.

[0047] The beneficial effects of this embodiment are: (1) The appearance of the prepared microemulsion composition is light yellow and semi-clear liquid. (2) After the prepared microemulsion composition is diluted 50 times, the measured average particle diameter is 70nm, which meets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com