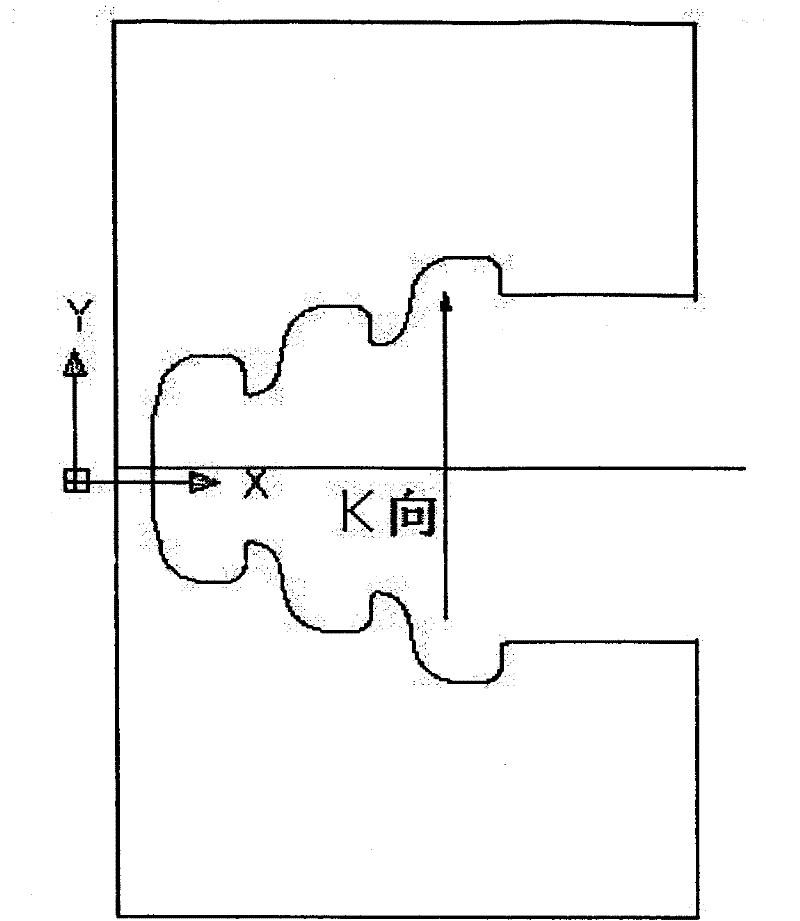

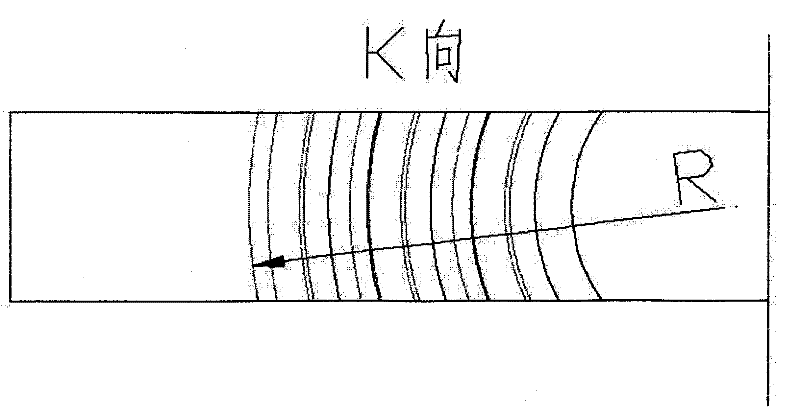

Method for processing slots on turbine rotor for mushroom-shaped blade roots

A steam turbine blade and processing method technology, which is applied in metal processing equipment, manufacturing tools, milling machine equipment details, etc., can solve the problems of poor structural rigidity of machine tools, affecting machining accuracy and smoothness, and large tool consumption, etc., and meet the requirements of reducing size , Reduce tool consumption and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

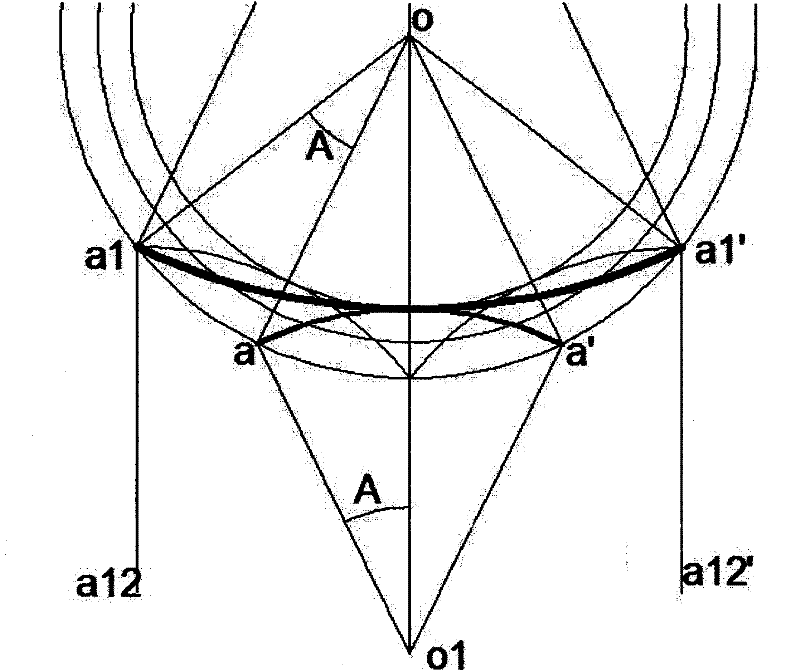

Embodiment Construction

[0052]In order to ensure the accuracy of the fungus-shaped blade root groove line without over-cutting or under-cutting, it must be strictly ensured that the tool axis vector at the contact point between the cutter and the blade root arc surface is consistent with the normal direction of the arc surface during the cutting process, that is, : The tool axis vector always points to the arc center. In machine tools where the tool cannot swing, this requirement can only be achieved by the rotation of the workpiece and the linear movement of the tool. That is: when the tool cuts the inflection point of the arc curve, the tool axis coincides with the normal line of the point; when the tool cuts other points of the arc curve, the tool axis is parallel to the normal line of the point, and the tool axis due to the rotation of the workpiece Changes in the position of the point of contact with the arc are compensated by the linear movement of the tool. After equidistant interpolation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com