Hand-holding power tool and processing method of outer shell thereof

A technology of electric tools and treatment methods, which is applied in the direction of manufacturing tools, pre-treated surfaces, and portable mobile devices, etc., can solve the problems of low dielectric strength, thin spray coating, short service life, etc., and achieve safe and reliable electrical insulation performance, Increase corrosion resistance, smooth and bright surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

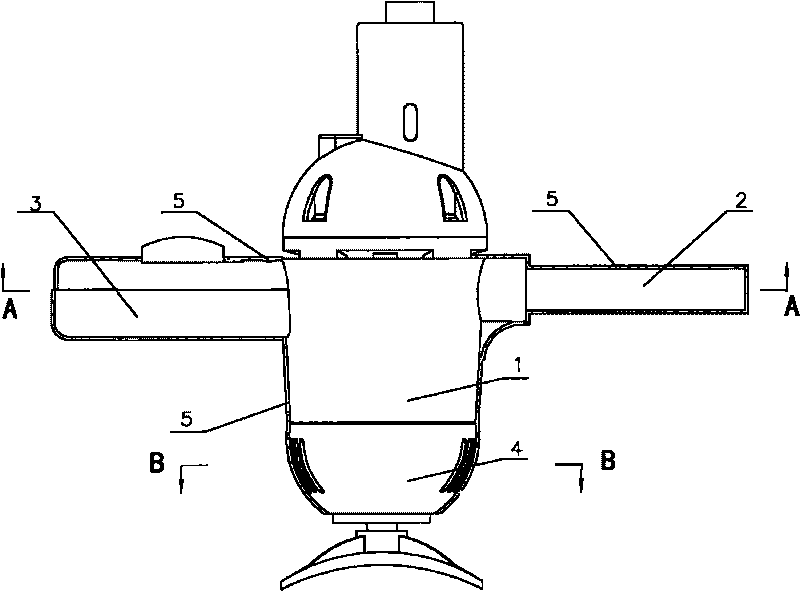

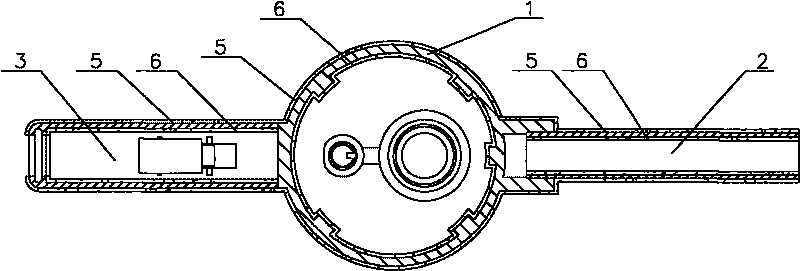

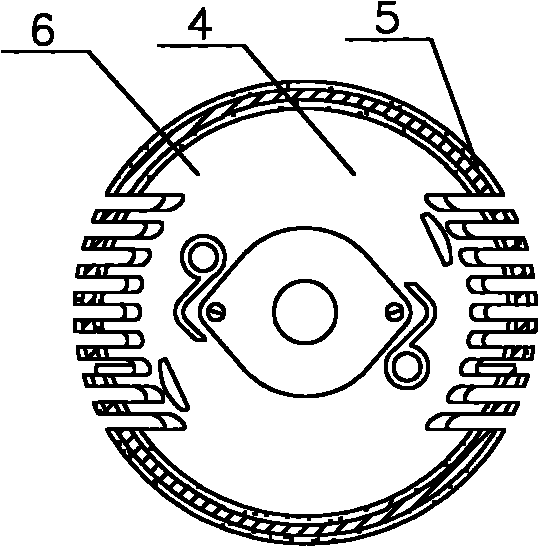

[0043] Such as Figure 1 to Figure 3 As shown, a hand-held electric tool taking a hammer drill as an example includes a hammer drill upper body shell 1, a hammer drill lower body shell 4, a first handle shell 2 and a second handle shell 3, and the hammer drill upper body shell 1, The outer surfaces of the lower body shell 4 of the hammer drill, the first handle shell 2 and the second handle shell are all provided with an outer surface coating 5, the upper body shell 1 of the hammer drill, the lower body shell 4 of the hammer drill, and the first handle shell 2 and the inner surface of the second handle housing 3 are provided with an inner surface coating 6 .

[0044] The material for making the inner and outer surface coatings is polyethylene. Because the friction degree of the inner surface of the hammer drill is small, the thickness of the inner surface coating 6 is set to 0.40mm, and because the friction degree of the handle part is large, the outer surfaces of the first h...

Embodiment 2

[0052] Such as Figure 4 to Figure 5 As shown, a common handle is taken as an example, including a handle shell 7, an outer surface coating 5 is provided on the outer surface of the handle shell 7, and an inner surface coating 6 is provided on the inner surface of the handle shell 7. The material of making the inner and outer surface coating of the handle shell 7 is polyvinyl chloride. Because the degree of friction of the inner surface of the handle housing 7 is small, the thickness of the inner surface coating 6 is set to 0.50 mm, and because the degree of friction of the outer surface of the handle housing 7 is large, the thickness of the outer surface coating 5 is set to 0.60 mm. mm.

[0053] The processing method of the handle shell 7, (the handle shell 7 is made of aluminum alloy.) The method comprises the following steps:

[0054]1. Surface treatment of the handle shell 7: first put the handle shell 7 into an aqueous solution containing a concentration of 20g / L phosph...

Embodiment 3

[0059] Such as Figure 6 , Figure 7 As shown, the hand-held power tool taking the sand mill as an example includes an upper body shell 8 of the sand mill and a lower body shell 9 of the sand mill, and the upper body shell 8 of the sand mill and the lower body shell 9 of the sand mill The outer surface coating 5 is arranged on the outer surface, and because the friction degree of the inner surface of the sand mill is small, no coating can be arranged on the inner surface. The material for making the outer surface coating 5 is polytetrafluoroethylene. The thickness of the outer surface coating 5 is set to 0.48mm.

[0060] The processing method of the shell of the hand-held electric tool sand mill, (in this embodiment, the upper body shell 8 of the sand mill and the lower body shell 9 of the sand mill are collectively referred to as the shell, and the shells are all made of aluminum alloy.) The method includes the following steps:

[0061] 1. Surface treatment of the shell: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com