Nano-hydroxyapatite/N-malely chitosan composite material, preparation method and application thereof

A nano-hydroxyapatite, acylated chitosan technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, catalytic reactions, etc., can solve the problem of reducing the contact rate of the degree of freedom of the catalytic active center , The catalyst preparation method is difficult to repeat, the catalytic activity and selectivity are reduced, etc., to achieve good complexing ability, improve chemical reaction activity, and excellent mechanical and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

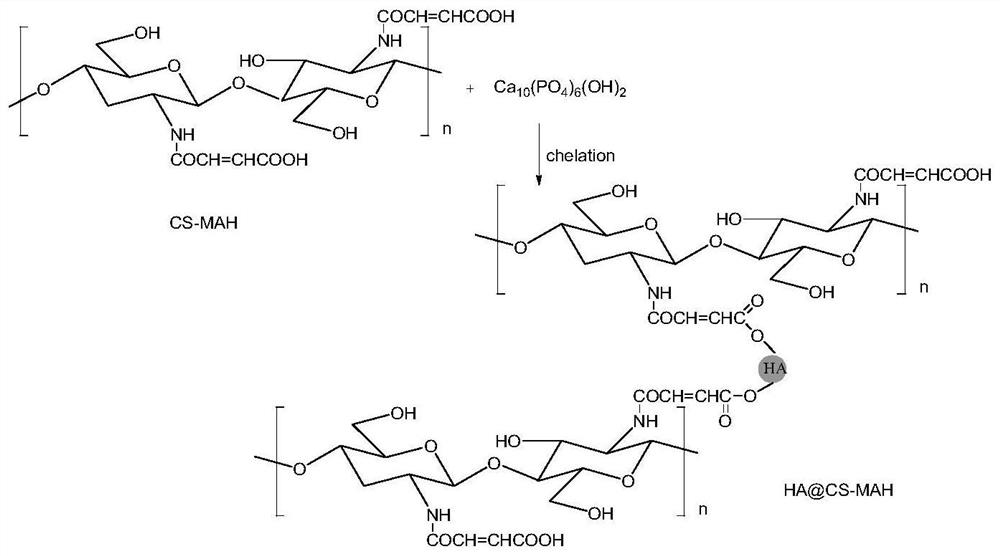

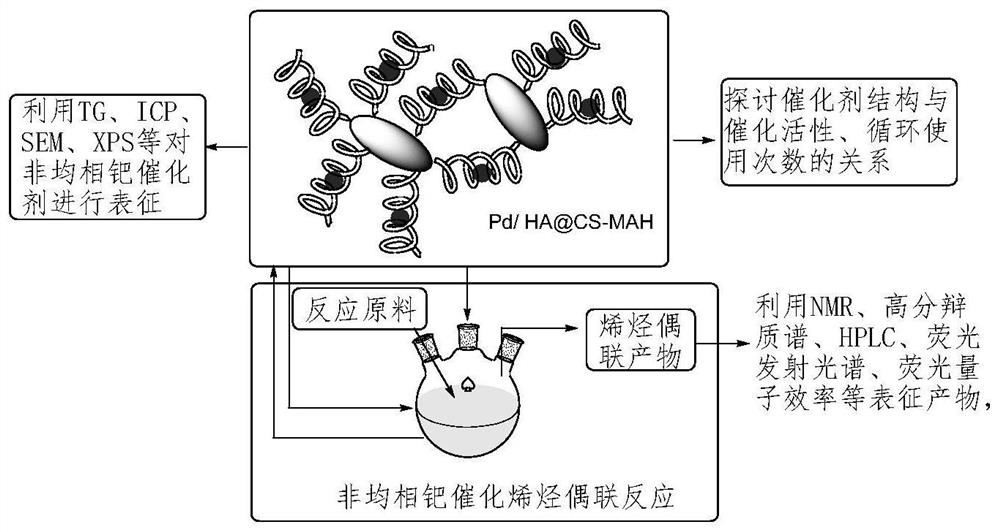

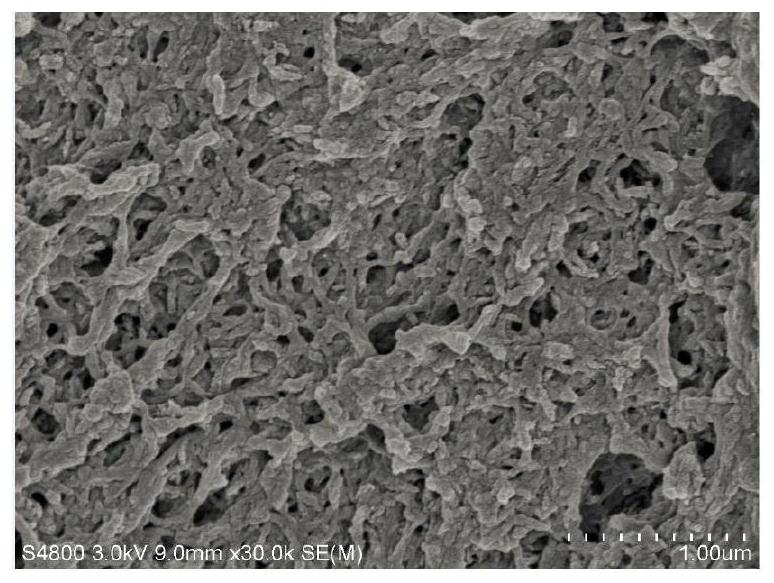

[0043] 1. Preparation of nano-hydroxyapatite / N-maleoylated chitosan composites

[0044] (1) Take the oyster shell and put it in a beaker after cleaning and air-drying, add a sodium hypochlorite solution with a mass fraction of 5%, soak at room temperature for 1 week, fully remove the protein, take out the oyster shell, rinse it repeatedly with water for 3 times, dry it, and crush it over 200 Mesh sieve, add sodium pyrophosphate into the reaction kettle, the molar ratio of calcium in oyster shells and phosphorus in sodium pyrophosphate is 5:6, add appropriate amount of deionized water, stir magnetically for 30min, seal the reaction kettle, and put it in an oven at 220 ℃ hydrothermal reaction for 6 hours; after the reaction, the reaction kettle was cooled to room temperature, and the product was taken out, washed with deionized water and absolute ethanol for 3 times, and dried at 80 ℃ to obtain nano-hydroxyapatite;

[0045] (2) Weigh 1.60g of chitosan and dissolve it in 100mL of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com