Gel-casting method of silicon nitride ceramic material containing silicon metal powders

A technology of gel injection molding and silicon nitride ceramics, which is applied in the field of gel injection molding of silicon nitride ceramic materials containing metal silicon powder, and can solve the problem of difficult gel injection molding near-net size molding and firing temperature High and unsatisfactory sintering shrinkage, etc., to achieve ideal sintering shrinkage, promote reaction sintering, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

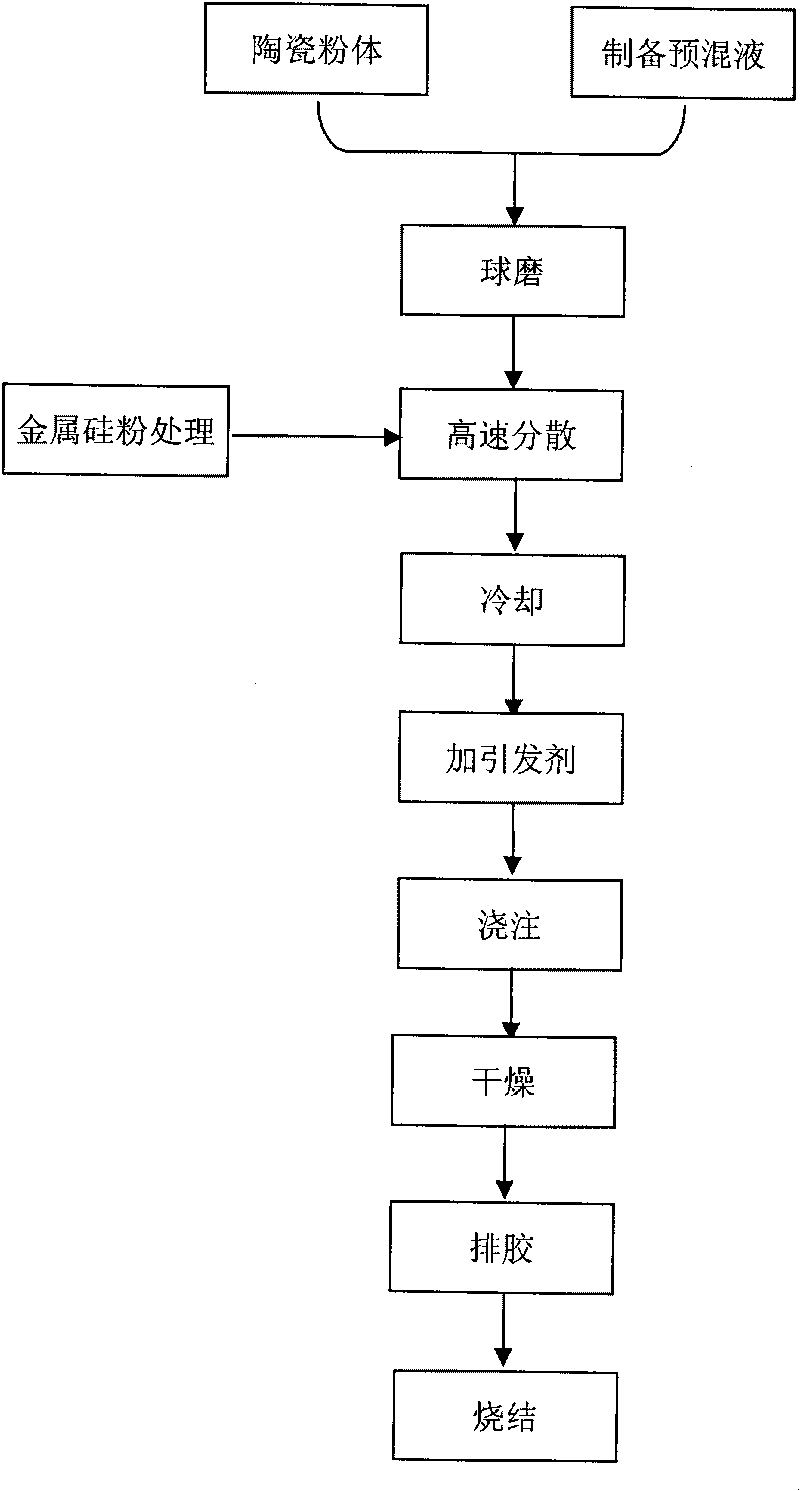

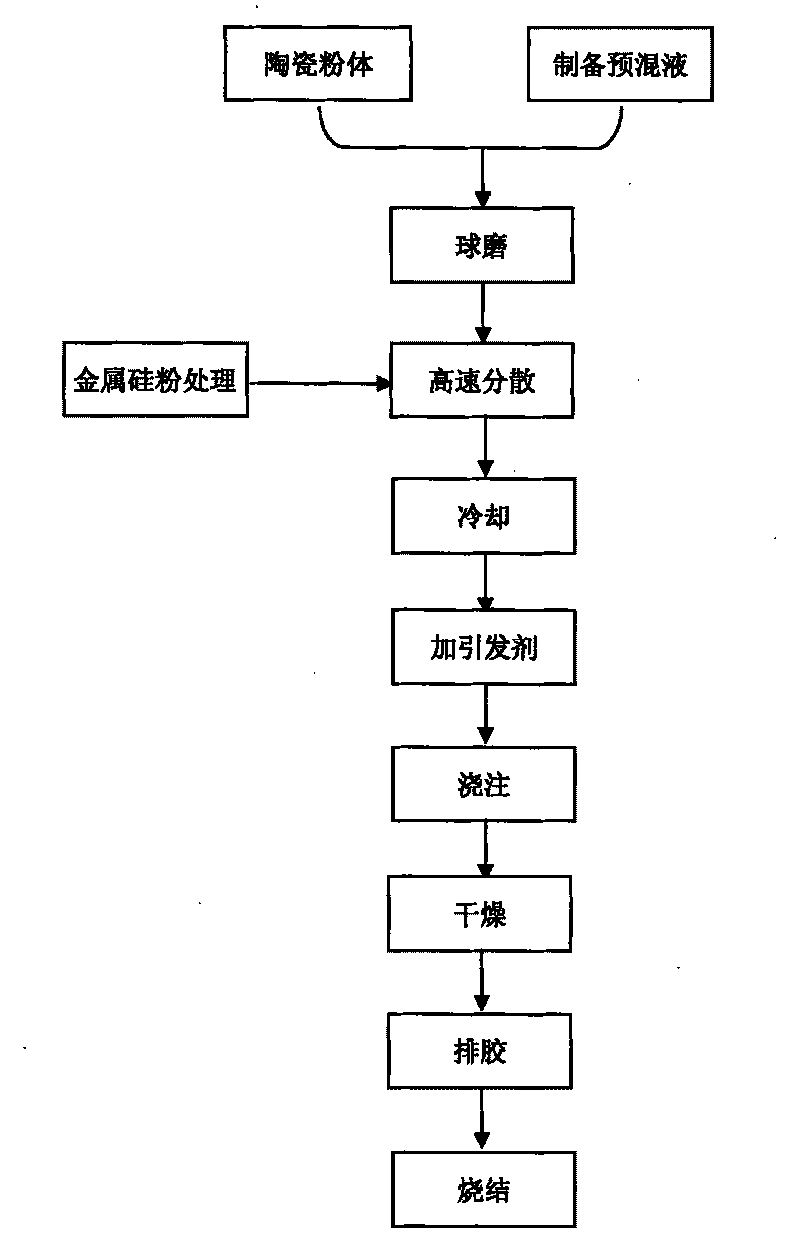

Method used

Image

Examples

Embodiment 1

[0048] (1) Pretreatment of metal silicon powder: Weigh 630g of metal silicon powder, mix 945g of agate balls and 630g of deionized water according to the ratio of material:ball:water of 1:1.5:1, and ball mill for 72h; then put the slurry in a beaker Place in the slurry for 5 days, stirring from time to time; after 5 days, add 3.15g of polysiloxane surfactant to the slurry, and stir for 2 hours; dry in an oven at 100°C to obtain metal silicon powder A, and set aside.

[0049] (2) Slurry preparation: Weigh 16 g of acrylamide, 1.6 g of methylene acrylamide, and 0.7 g of dispersant ammonium polyacrylate, dissolve in 181.7 g of water, filter to remove impurities, and obtain a clear solution, which is the premix. Take premix 50g, weigh MgO35g, weigh Y 2 o 3 35g, placed in a ball mill jar, mixed and ball milled for 24 hours to obtain a sintering aid slurry, immediately pour it into a beaker, slowly add the metal silicon powder A treated in step (1), and gradually add 150g of the rem...

Embodiment 2

[0054] (1) Pretreatment of metal silicon powder: Weigh 630g of metal silicon powder, mix 945g of agate balls and 630g of deionized water according to the ratio of material:ball:water of 1:1.5:1, and ball mill for 24h; then put the slurry in a beaker Place in the slurry for 4 days, stirring from time to time; after 4 days, add 0.25g of polysiloxane surfactant to the slurry, and stir for 2 hours; dry in an oven at 100°C to obtain metal silicon powder B, and set aside.

[0055] (2) Weigh 40 g of acrylamide, 2 g of methylene acrylamide, and 1.0 g of ammonium polyacrylate as a dispersant, dissolve them in 157 g of water, filter to remove impurities, and obtain a clear solution, which is the premix. Take premix 100g, 5g, weigh Si 3 N 4 215g, weighing Y 2 o 3 8g, weigh 7g of MgO and place it in a ball mill jar, mix and mill it for 24 hours, pour it into a beaker immediately, slowly add 250g of metal silicon powder B processed in step (1), and gradually add 100g of the remaining pr...

Embodiment 3

[0060] (1) Pretreatment of metal silicon powder: Weigh 630g of metal silicon powder, mix 375g of agate balls and 250g of deionized water according to the ratio of material:ball:water of 1:1.5:1, and ball mill for 24h; then put the slurry in a beaker Place in the slurry for 2 days, stirring from time to time; after 2 days, add 1.26g of polysiloxane surfactant to the slurry, and stir for 2 hours; dry in an oven at 100°C to obtain metal silicon powder C, and set aside.

[0061] (2) Weigh 20g of acrylamide, 1.5g of methylene acrylamide, and 1.4g of ammonium polyacrylate as a dispersant, dissolve them in 178.5g of water, filter to remove impurities, and obtain a clear solution, which is the premix. Take 50g of the premixed solution, weigh Si 3 N 4 50g, weighed Al 2 O10g, weighing Y 2 o 3 10g, placed in a ball mill jar, mixed and ball milled for 24 hours to obtain a sintering aid slurry, immediately pour it into a beaker, slowly add 630g of the metal silicon powder C processed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com