Bridged polysilsesquioxane, monomer thereof and preparation method for two

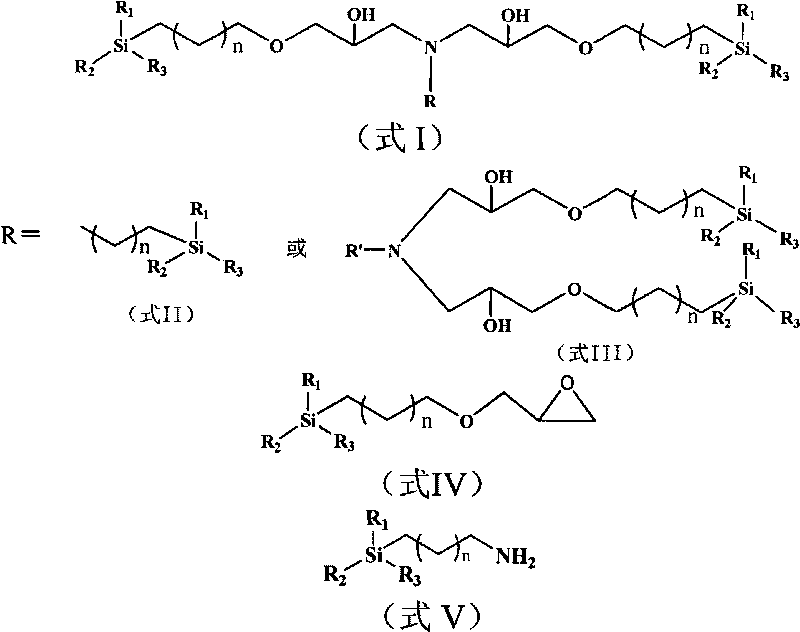

A technology of polysilsesquioxane and silane monomers is applied in the field of bridged polysilsesquioxane and its monomers and their preparation. High yield, simple synthesis method, mild process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Under nitrogen protection, 45ml of 3-(2,3-epoxypropoxy)propyltrimethoxysilane was added to a three-necked flask equipped with a condenser, a thermometer and a dropping funnel, and then 18ml of 3-aminopropyl Trimethoxysilane, heated to 70°C, reacted for 48 hours to obtain a light yellow bridging monomer.

[0030] There are 9 trialkoxy groups in the bridging monomer obtained, take 5ml of the bridging monomer and dissolve it in 10ml of tetrahydrofuran, add 1ml of formic acid aqueous solution with a mass percentage concentration of 88%, and leave it open at 50°C for 24 hours. A bridged polysilsesquioxane is obtained.

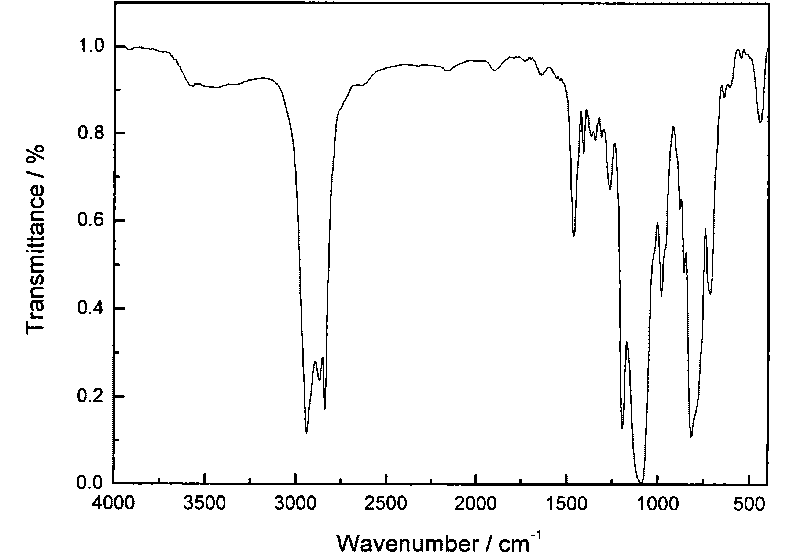

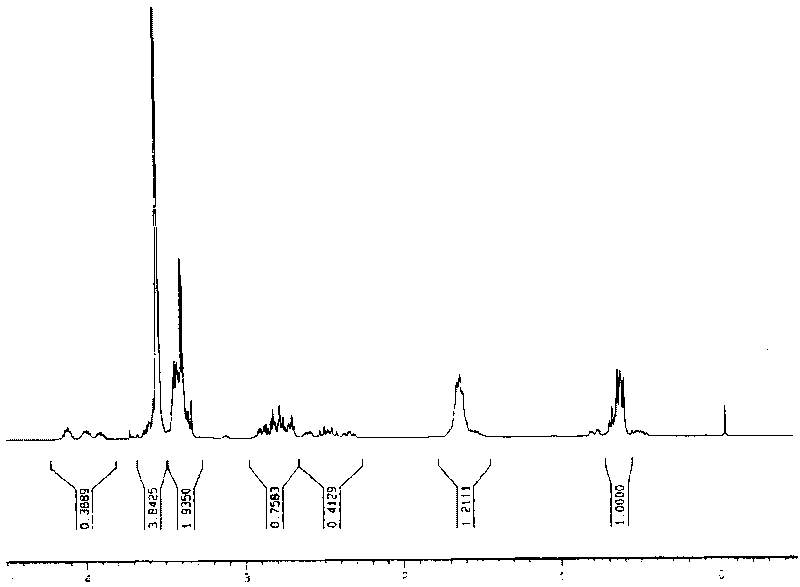

[0031] The infrared and nuclear magnetic resonance spectra of the compound are as follows figure 1 with figure 2 shown. It can be seen from the figure that the structure of the compound is correct.

Embodiment 2

[0033] Under nitrogen protection, 23ml of 3-(2,3-epoxypropoxy)propyltrimethoxysilane was added to a three-necked flask equipped with a condenser, a thermometer and a dropping funnel, and then 12ml of 3-aminopropyl Triethoxysilane, heated up to 70°C, reacted for 48 hours to obtain a light yellow bridging monomer.

[0034] There are 9 trialkoxyl groups in the bridging monomer obtained. Dissolve 5ml of the bridging monomer in 10ml of methanol, add 1ml of formic acid aqueous solution with a mass percentage concentration of 88%, and leave it open at 50°C for 24 hours. A bridged polysilsesquioxane is obtained.

Embodiment 3

[0036] Under nitrogen protection, 43ml of 3-(2,3-epoxypropoxy)propylmethyldimethoxysilane was added to a three-necked flask equipped with a condenser, a thermometer and a dropping funnel, and then 16ml of 3- Aminopropylmethyldimethoxysilane, heated to 70°C, reacted for 48 hours to obtain a light yellow bridging monomer.

[0037] There are 6 trialkoxyl groups in the bridging monomer obtained. Dissolve 5ml of the bridging monomer in 10ml of tetrahydrofuran, add 1ml of formic acid aqueous solution with a concentration of 88% by mass, and leave it open at 50°C for 36 hours. A bridged polysilsesquioxane is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com