Efficient compound anti-swelling oil displacement agent and method for preparing same

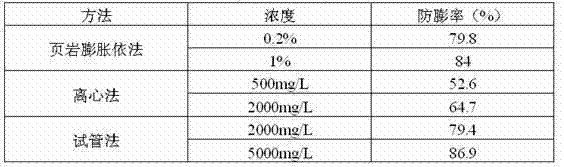

An oil displacement agent and high-efficiency technology, applied in the field of high-efficiency composite anti-swelling oil displacement agent and its preparation, can solve the problems of not considering the expansion of rock formations, not paying attention to the geological characteristics of reservoirs and the physical properties of crude oil, etc., and achieve good calcium soap dispersion performance, improving oil washing efficiency, and good wetting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

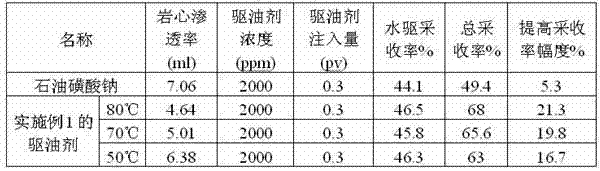

Examples

Embodiment 1

[0044] At normal temperature and pressure, to the 2m with condenser 3 Add 800kg of polyacrylamide and 400kg of dichloroethane into the stainless steel reaction kettle, start stirring, react at 90°C for 15 hours, control at 0.6MPa, add 300kg of sodium octylbenzenesulfonate, 200kg of potassium alginate and 100kg of NaOH, and react for 10 hours. Pass condensed water, cool down to 30°C, add 300kg of KCl, and continue stirring for 1 hour to obtain 2 tons of the product, which is stored and packaged.

Embodiment 2

[0046] At normal temperature and pressure, to the 2m with condenser 3 Add 882kg of polyacrylamide and 441kg of dichloroethane into the stainless steel reaction kettle, start stirring, react at 80°C for 14 hours, control at 0.6MPa, add 252kg of sodium octylbenzenesulfonate, 168kg of potassium alginate and 63kg of NaOH, and react for 8 hours. Pass condensed water, cool down to 15°C, add 294kg of KCl, and continue stirring for 1 hour to obtain 2 tons of product, which are stored and packaged.

Embodiment 3

[0048] At normal temperature and pressure, to the 2m with condenser 3 Add 800kg of polyacrylamide and 400kg of dichloroethane into the stainless steel reactor, start stirring, react at 90°C for 12 hours, control at 0.5MPa, add 300kg of sodium octylbenzenesulfonate, 200kg of potassium alginate and 100kg of NaOH, and react for 6 hours. Pass condensed water, cool down to 30°C, add 300kg of KCl, and continue stirring for 0.5 hours to obtain 2 tons of the product, which is stored and packaged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com